Types of antifreeze adhesives for granite for outdoor use, rules of use

Facing the facades, marble plinths, granite makes the architecture more expressive. Natural stone is very durable and extends the life of brick and concrete walls. The coating is influenced by solar radiation, rain, snow, wind, temperature differences. For outdoor use, a frost resistant granite adhesive is required. Inside, especially in swimming pools, artificial reservoirs, the glue must be waterproof.

Basic Adhesive Requirements

Marble and granite give exterior and interior cladding a noble and expensive look. Its service life depends on the glue with which the stones are connected to the surface of facades and flooring.

Versatility

The adhesive composition should be equally effective when performing external and internal work, resistant to temperature extremes.

Strength

The glue should be inert to alkalis, acids and ultraviolet light.

Sustainability

The density of the adhesive should not change for a long time, so that compression and cracking do not occur.

Solidification rate

The faster the marble or granite slabs are glued, the higher the quality of work.

Which glue is right

The choice of glue depends on the characteristics specified by the manufacturer and the price.

cement based

The adhesive composition includes cement grades M400, M500, M600. Inexpensive funds are used for interior and exterior work. Frost resistance depends on additives.

Polyurethane

Synthetic adhesive based on polyester. Produced in the form of putty. Curing speed depends on air temperature. The composition does not interact with aggressive media.

Properties deteriorate with prolonged high humidity.

Polyester

Two-component composition for bonding marble, available in three consistencies:

- fluid;

- viscous;

- solid.

The multi-color range allows you to use it to decorate mosaic panels.

Epoxy

The two-component composition has good adhesion properties on concrete, metal, stone, withstands low temperatures. It is used for exterior and interior cladding of structural elements of buildings.

Impregnating

Adhesives of this type are produced in the form of a gel that penetrates into the pores of the stone, the cracks. After hardening, it acquires monolithic properties with a stone, amenable to grinding, polishing. The tool is used for outdoor work due to its resistance to low temperatures and atmospheric influences.

Review of the best manufacturers

Manufacturers from Germany, Russia and Italy have a high rating in the marble and granite adhesive market.

Elastorapid

The Italian company Mapei specializes in the production of construction chemicals. Under the Elastorapid brand, its assortment is sold through distributors in the Russian Federation. One of the products is hard paste adhesives. The main components are silicate sand and latex. The formulations are safe for health and the environment.

Kreps Plus

The largest Russian manufacturer of dry building mixtures. The basis of adhesives for ceramics and stone is cement, river sand, modifiers.

Eunice

The United group of companies occupies a leading position in the production of building materials in the Russian Federation and the CIS countries. The product range includes more than 90 references, including adhesives for tiles and natural stone. The basis of the adhesives is high-quality cement and modifying additives.

Keraflex

The company was founded in 2004 in the Ryazan region. Specialization - dry mixes, including adhesives for tiles, artificial and natural stone.

Keralastic T

Under the Keralastic and Keralastic T brands, Mapei manufactures two-component polyurethane adhesivesThe compositions are used for interior and exterior coatings. Official distributor in Russia - StroyServis.Su.

Ceresit

The German brand Ceresit has been known since the beginning of the 20th century.

In the Russian Federation, the company opened four factories:

- in Kolomna;

- Chelyabinsk;

- Nevinnomyssk;

- Ulyanovsk.

One of the company's activities is tile adhesive. The products are certified and are in high demand due to their high quality.

Belfix

Yunis Group of Companies Publications glue under the Eunice Belfix brand for laying decorative materials on floors and walls. Products are certified in accordance with the legislation of the Russian Federation.

Ranking of the best brands

Brands based on cement, polyester, epoxy resins are in demand.

United Granite

Composition: cement, mineral and chemical additives. We recommend use in a temperature regime not higher than +30 and not lower than +5 degrees. Objective: fixing large format slabs of natural and artificial stone on the facades of buildings.

The basis can be:

- concrete;

- gypsum;

- brick;

- cement;

- asphalt.

The pot life of the solution is approximately 5 hours.

Litokol Litoelastic A + B

Epoxy adhesive belongs to the class of two-component reagents, which contains resin and hardener. It is used in civil and industrial construction for coating vertical and horizontal surfaces. Has increased strength, frost resistance.

Professional Quick Stone

The adhesive composition withstands temperature extremes from -50 to + 70 degrees, has good adhesion. Objective: covering the facades with natural stone.

Knauf Flysen

Dry adhesive cement for bonding marble and granite tiles with dimensions of 30 x 30 centimeters or more.

Knauf flysen more

Cement-based adhesive for interior and exterior coating of floors, stairs, skirting boards and facades.

Quarzo Tenax solido

Polyester adhesive sealant from the Italian manufacturer. White paste that can be tinted with Tenax dyes. Appointment: for facing of horizontal surfaces, repair, reconstruction of natural stone compositions.

Bellinzoni-2000 putty

Cream polyester putty from the Italian company Bellinzoni has a wide range of colors, applicable up to a temperature of 0 degrees. Available in a liquid and thick consistency. Objective: to work with natural and artificial stone.

Akepox 1005

Liquid epoxy adhesive. It is used for laying, repairing light natural stones. Resistant to weathering, low temperatures.

Isomat Ak-Epoxy Normal

2-component, solvent-free epoxy adhesive. They are used for covering floors and walls, on all types of surfaces, for exterior and interior work.

Aquapox

The adhesive has an ultra-high fluidity, colorless, based on resins and hardener. Recommended for exterior bonding with granite or marble. The composition is resistant to aggressive environments.

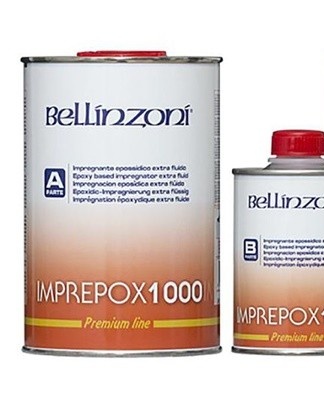

Imprepox

Liquid epoxy adhesive. Manufactured by Bellinzoni. Applications: surface restoration and bonding of all types of natural and artificial stone.

Somafix

Adhesive based on polyester resin. Purpose: glue marble and granite.

How to choose the right one

A high quality coating can be achieved provided the correct brand of glue is selected. This will determine the strength of adhesion of the stone to the base, which means the durability of the work done. Each option requires its own brand of glue, which must correspond to the type of facing and the type of stone. Stone tiles have different thicknesses and sizes.

Adhesives have different working times after preparation. The optimal retention period for adhesive properties is 3 hours. This allows tiles to be laid with good performance.

For facade works, the glue must have:

- a vertical retention indicator of 70-80 kilograms;

- frost and frost resistance to frost at least 35 times;

- waterproof qualities;

- resist low/high temperature cooling/heating;

- color matching.

The marble slabs are glued with colorless glue.

How to paste

The choice of brand depends on the location and type of stone tile to be bonded, as well as its condition.

From granite to granite

For carrying out work indoors, polyester glue is used, which can be used up to a temperature of 0 degrees. When choosing a composition, one should take into account its consistency:

- For a solid connection of horizontal plates, a liquid form is used.

- The semi-thick composition fills the pores of the stone, restoring its strength. Once hardened, it lends itself to grinding and polishing, creating a monolithic bond.

- The walls are covered with a thick glue which, due to its high viscosity, does not slip vertically holding the tiles.

When working with polyester compounds, add the hardeners specified in the instructions. In order for the junction to be inconspicuous, a transparent or a glue suitable for the shade is selected.

Marble tiles

For finishing marble, polyester and epoxy glue are used. Polyester glue can be liquid, semi-liquid and thick. It is used indoors. Add a hardener putty before use. Epoxy is used for interior and exterior wall cladding.

Granite tiles

Epoxy glue has a high degree of adhesion to the material, which makes it possible to glue granite not only on granite, but also on concrete, metal, wood. The composition can be used for interior and exterior coatings, as it retains properties from -30 to +60 degrees, it is resistant to moisture and ultraviolet light.

The liquid form is used for horizontal surfaces, thick - for vertical ones.After hardening, the glue is sanded and polished. An adhesive is prepared according to the instructions before starting work.

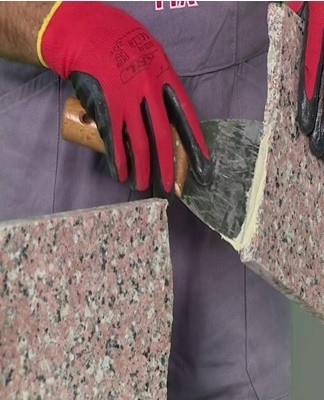

General rules for using glues for working marble and granite

The rules for using adhesives for natural stone differ depending on the place of facing. The general rule is to prepare the workplace and the equipment. They are cleaned of dust and dirt. The amount of adhesive should match the surface of the stone slabs to be bonded.

outdoor work

Exterior coating works are carried out with cement and epoxy compounds. Both types of glue are prepared just before gluing. Water or latex is added to the dry mix, and the hardener is added to the epoxy resin in the proportions indicated by the manufacturer.

It is necessary to use the adhesive within the specified time. The adhesive remaining over time loses its properties. You cannot add new portions to it and mix.

Internal work

Interior walls can be concrete, plaster, brick. Before proceeding to gluing, they must be cleared of paint, wallpaper. Floors and walls are checked with a level so that the stone slabs do not protrude above each other.

Additional tips and tricks

Epoxy and polyester glues are harmful to the skin. When working with them, you need to protect your hands with gloves. Cement mixes generate dust when agitated, lifting the smallest particles of cement and gypsum into the air.

To avoid getting into the lungs, it is necessary to prepare the glue in a respirator.

Different adhesives are used to create marble and granite coatings. The surface of the marble will stain if the adhesive contains dyes or salts. Granite has less porosity and does not require special care when choosing an adhesive.

Marble for exterior cladding is used in the climatic conditions of subtropical regions. In temperate zones and further north, it quickly loses its attractive appearance: it loses its color (dark), becomes dirty and cracks with frost. In cities with significant industrial and automobile emissions, it begins to crumble. It is imperative to impregnate marble surfaces from time to time with water and dirt repellent agents. After laying, granite does not require such protection if there is no constant humidity and pollution.

The thickness of the layer depends on the type of adhesive and the facing method. Liquid epoxy and polyester compositions are applied no more than 1-2 millimeters, semi-thick - up to 3 millimeters, thick - up to 4 millimeters. The layer of cement should not exceed 1.5 centimeters.