Cold Weld Bonding Instructions, Best Brands and How to Apply

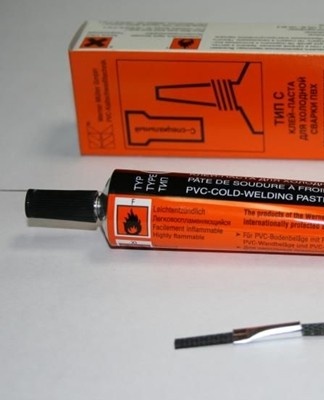

Cold welding with glue solves many heterogeneous problems: the polymer composition reliably holds the parts to be joined, creating a joint insensitive to stress and temperature. This method has been called welding because of its unique strength characteristics. And you don't need to heat anything: you need to prepare the mixture at room temperature, apply to the repair area, connect.

general description

It is not correct to call this method "welding". The actual welding process is associated with high-temperature diffusion of particles from a special electrode into the body of the metal to be welded. In this case, the parts can deform and even crack. The cold method is devoid of these drawbacks and in terms of the strength of the resulting seam it can compete with others.

Composition and properties

By purchasing a cold welding kit, the consumer receives a ready-to-use one- or two-component composition (sometimes with reinforcing additives).There are also heat resistant options. The adhesive is polymer based (epoxy resin). When combined with a hardener, a chemical reaction occurs, a strong seam is formed.

Varieties and producers

The industry has mastered the production of cold welding of the following types:

- for motorists;

- for plumbing work;

- for bonding metals;

- universal.

There are domestic and foreign brands. We study the compositions in order to choose the one you need.

Universal

As the name suggests, this composition is suitable for most situations. Withstands temperatures up to 260 degrees without destruction. In some cases, where welding is required underwater or particularly strong, these properties will not suffice. In everything else, the quality offer of the universal remedy is more than sufficient.

For metal products

As a polymer for assembling ferrous or non-ferrous metal products, ductile iron must have specific properties. This includes strong stitching and adding additional components.

Welding under water

A non-standard way of joining parts - under water - will be in demand in plumbing, when it is impossible to drain the working area.

For auto repair

Car enthusiasts often need to repair cracks, through holes in body parts, and eliminate leaks in the radiator. Cold welding will ensure flawless work performance even at home without resorting to expensive service.

Review of popular brands and manufacturers

To understand unknown names and brands, consider the most popular of them. At the same time, we will study a brief description of the composition, advantages and disadvantages.

diamond

Russian manufacturer producing universal glue. Delivered in plastic tubes, inside which is a mixture wrapped in polyethylene. It consists of two layers: outside - resin, inside - hardener. It will be enough to roll a small sausage in your hands, mixing the components so that the mixture hardens. Disadvantages: not resistant to high loads, suitable for home use.

Polymet

Another national manufacturer recommended for critical connections, including those operating at high temperatures.

weicon

Cold welding for a wide range of applications. Focused on the repair of metal products in titanium, aluminum, steel, copper, plastic, wood and concrete. It is well sawn, drilled, sharpened (frozen). Withstands up to 300 degrees.

hi-speed

Adhesive is shown as ironwork oriented. One of the types is called "high-speed steel". Withstands a seam shear force of 1.2 thousand Newtons.

Recommended to complete a car enthusiast's travel kit.

Poxipol

Universal composition for home, summer cottages, garage repairs. Binds plastic, metal, wood, not afraid of snow, rain, dust.

Abro

American glue recommended for motorists. Suitable for repairing damage to crankcase, battery, bodywork or even engine block. It is used as a composition for the restoration of sanitary ware, withstands high temperatures. Black color. Oil resistant.

Permatex

A universal compound that can resist shear and pull-out loads. Gives a stable result, is irreplaceable in the household.

mastix

The composition of the mastic is tested for resistance to contact with water, in the repair of heating radiators.It can work even without drying the contact surfaces.

Henkel

The German manufacturer is known for its Supermoment product. Differs in stable indicators of seam strength, but it cannot withstand large tensile loads.

Wurth Liuguid Metal Fe 1

The products of the manufacturer from the Federal Republic of Germany demonstrate, in a pull-out test, resistance to a force of 2 megapascals, but cannot withstand shear stress.

Kerry "Thermo"

A highly specialized composition with metallosilicates, oriented at temperatures up to 900 degrees. Suitable for automotive repairs, filling cracks and sinks.

Homakoll s401

Designed to assemble PVC, linoleum. Provides a durable and elastic seam. This limits the scope of application of the glue.

Amethyst

Cold welding for metal and plastic. It gives a good result, made in Russia. The frozen composition lends itself to mechanical processing - it is sharpened, cut, sawn.

How to use correctly

In order for the seam to be really strong, certain conditions will have to be met. Surfaces should be prepared, cleaned with fine grit emery paper and wiped with acetone. Depending on the application, cold welding can join parts, restore geometry, seal cracks and crevices. The product is completely ready to use once the mixture has hardened.

Coaching

First of all, they study the instructions for use to ensure that the composition is suitable or not for the given needs. Cleaning of dirt, dust, grease, traces of corrosion will increase the strength of the seam, ensure contact between the surfaces to be glued. This also includes degreasing and some roughing for better grip.

Manual

Instruction - the main document of the adhesive, its "passport".The mode of application, the duration of polymerization are indicated there. Specified in the instructions and the materials for which cold welding is intended. Therefore, before starting work, it should be studied as carefully as possible. The method of applying the glue is also indicated there:

- by dots;

- sewing;

- at the joint.

Point

If the instructions prescribe applying the glue pointwise, then this must be done.

Suture

This method can be used to create a strong, load-bearing joint.

End

It is used to join parts into a joint, with minimal consumption of glue and a visually invisible seam.

Tavrovaya

The T method is used when connecting on the contact area. For example, in electrical engineering.

Shear welding

Shear welding makes it possible to join pipes of different diameters when one part is inserted into another.

Additional tips and tricks

Cold welding is used everywhere, but most often it is used by motorists. When the muffler burns out, the crankcase or the radiator leaks, a tube of glue is irreplaceable.

In order for the choice of composition to justify expectations and not disappoint you, they carefully study the operating conditions of the assembly or part, as well as the instructions on the package with glue. For high temperature environments, a suitable product is required. The same applies to parts in contact with liquids.

Oil-resistant adhesives deserve special mention, there are also such adhesives. Metal is best connected by compounds with additives that improve adhesion and joint strength. Cold welding does not tolerate pressurized fluids well.Universal adhesives, in fact, have a narrow scope: if special working conditions are required, it is better not to save money, but to purchase a specialized product with the required properties.

The quality of the joint and the durability of the restored product largely depend on the preparation of the surfaces to be bonded. This involves cleaning, degreasing, dusting, removing traces of moisture and roughening with fine sandpaper. And you can use a ready-made knot, a glued part, not until the seam is finally cured. The setting time of the composition can be found in the instructions.