How to quickly paint a metal fence, the choice of composition and the rules of application

A metal fence is durable, reliable, aesthetic, but, like a wooden fence, it needs protection from adverse factors. The choice of coloring compositions for metal is large, the paint should give the surface a decorative look, be resistant to temperature extremes and precipitation, and protect against corrosion processes. There is a clear technology on how to paint a metal fence, it must be followed step by step to achieve the desired result.

Content

- 1 Basic requirements for the coloring composition

- 2 Suitable types of paints

- 3 How to choose the right paint primer

- 4 Varieties of painting tools

- 5 Stages of painting a new fence with your own hands

- 6 How to properly remove paint (LCP) from an old fence

- 7 The procedure for applying paint to an old fence

- 8 Solve common problems

Basic requirements for the coloring composition

When choosing a paint, special attention is paid to two characteristics: resistance to temperature fluctuations and adhesion capacity (the degree of adhesion to a metal surface).

The correspondence of the different coloring compositions to the specified requirements is shown in the table:

| Kind of paint | Compliance | Inconsistency |

| alkyd | excellent grip | loss of stability with increasing temperature |

| oil | resistance to humidity and overheating up to 80°C | burns quickly, cracks |

| acrylic | strong adhesion for a long time, no burnout and cracking, pronounced anti-corrosion properties | |

| universal | excellent adhesion with coating of surface imperfections, resistance to mechanical stress and all weather factors, painting an unprepared metal fence is allowed |

For painting a non-ferrous metal fence, it is advisable to take acrylic or a composition based on an organic solvent. For galvanized surfaces, acrylic and alkyd compounds are optimal. Oil and anti-corrosion paints are good for a ferrous metal fence.

If you want to paint your fence in an antique style, you can use acrylic with a brass, bronze or copper effect. Also, to get the effect of antiquity, you can apply crackle varnish, quaintly crackling when dry.

Suitable types of paints

It is difficult to choose the right paint, because the choice in the construction market is wide. When buying, you should familiarize yourself with the technical characteristics and composition. You must purchase a coloring matter suitable for the surface to be painted.

Black-smith

Universal paint that reliably adheres to any metal surface, including colored, galvanized, cast iron, steel. If you paint a fence with blacksmith's paint, its service life without the slightest trace of corrosion will be at least 10 years. The painted surface is reliably protected against scratches, moisture, ultraviolet radiation and strong temperature fluctuations.

Blacksmith paint is available with bronze, copper, gold, silver, platinum effect, as well as with a greenish tint, giving the effect of antiquity. After purchasing blacksmith paint, it is advisable to purchase solvent and primer from the same manufacturer. When used together, the materials make the coating as strong and shiny as possible and improve adhesion.

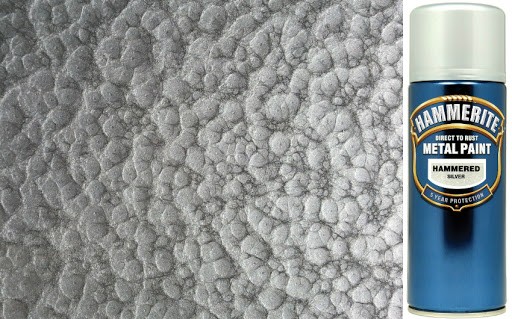

Molotkovaya

Another universal option for metal siding is recommended for fences affected by rust of varying degrees of intensity.

If you paint an iron fence with hammer paint, its appearance will change, surface defects will be smoothed out. Visually, it will seem that the fence is made by the method of artistic forging. To paint the fence with hammer compound, you do not need to prime it first, remove the oily layer. Excellent adhesion and ability to neutralize grease stains. But you need to paint quickly, applying only one layer, otherwise the surface will turn out bumpy, ugly.

Thanks to its anti-corrosion effect, it is possible to paint a rusty fence without prior cleaning. The active components of the composition prevent rust from spreading, protect the metal surface from the negative effects of moisture for at least 10 years.

Acrylic

The most popular compound for painting a metal fence.

Acrylic adheres well to profiled sheets, cast iron, galvanized steel, non-ferrous metals. It is easily removed from the skin, so after work, just wash your soiled hands. Many manufacturers produce high-strength acrylic paint, which is not afraid of mechanical stress.

alkyd

Due to its excellent adhesion, it is ideal for coating galvanized metal. Creates a dense film on the surface of the fence with high resistance to moisture and mechanical friction.

Advantages of alkyd paint - quick drying, even application. However, the composition contains a considerable percentage of toxic components, so it is impossible to work without a respirator. Alkyd paint is also included in the fire hazard category because kerosene acts as a solvent component.

Oil

You can paint a fence with oil paint only as a last resort, if financial possibilities do not allow you to purchase a more suitable material. This composition is optimal for interior finishing works, has excellent moisture resistance. But outside, under the influence of ultraviolet radiation and other weather factors, it will quickly crack and fade.

Rubber

A type of acrylic paint, after drying, forms an elastic, stretchable coating. To create the rubber effect, acrylate latex is added to the acrylic, a coalescent is added to form a film after drying, and water acts as a solvent.

Aluminum, steel and galvanized fences can be painted with rubber paint.

Anti-corrosion or anti-rust

A universal paint that prevents corrosion processes can be used for painting a fence made of cast iron, steel, non-ferrous metal, as well as posts between fence sections, profiled sheets and fittings. No priming or degreasing is necessary. Paint is optimal for a fence on which corrosion has already begun, it does not allow the destructive process to develop further, which extends the life of the structure.

To test the anti-corrosion properties of a paint, an experiment can be carried out:

- Take a piece of metal from which the fence is made. Paint it.

- Wait a few days for the coating to dry well.

- Soak the painted metal in a container of saline solution (10 large spoonfuls per liter of water).

- See if corrosion processes appear on the metal.

Criteria for choosing the optimal composition

When choosing a paint suitable for painting a fence, consider the following criteria:

- the material from which the fence is made;

- weather conditions in different seasons of the year in the territory of the fence;

- a sufficient degree of adhesion;

- resistance to external influences;

- financial opportunities;

- expiration date.

How to choose the right paint primer

The function of the primer is to protect the surface of the fence from negative weather factors and corrosion processes. The material also makes the paint layer smoother and denser. The fence is primed before staining.

Primers are used:

- tread - forming a dense film with high resistance to mechanical damage and moisture;

- insulation - high strength, moisture resistant;

- passivation - resistant to temperature fluctuations, providing excellent anti-corrosion effect;

- phosphating - the formation of a phosphate film, increasing strength, resistance to corrosion and wear, used for any type of metal, but only after cleaning the surface.

To paint a metal fence, mainly primers that are effective against corrosion and prevent the formation of rust are used.

Varieties of painting tools

There are many tools suitable for painting the fence, everyone chooses the one that suits them best. Usually they use a brush, roller or spray gun to paint the fences. Tools can be used together, combined.

Roll

A paint roller is the best option if you need to paint a large, even surface. The tool provides even coverage, but you'll need to use a small brush to touch up corners, edges, and indentations.

The roller is not used for priming. Possessing a porous structure, it leaves the smallest air bubbles in the applied layer, due to which rust gradually appears.

Brush

The most common tool is available in different sizes and thicknesses.When you buy a brush, you have to bend the bristles in your hand. If a mechanical action causes the hairs to fall out, it is not worth buying such a brush, otherwise the surface of the fence will be covered with dried hairs.

Spray gun

A spray gun is the best option for painting a large area quickly. No special skills are required, the paint is sprayed from the bottom of the fence upwards at an angle of 90 ° to the surface.

Stages of painting a new fence with your own hands

To get a beautiful fence that will last a long time without repainting, you need to paint according to the following algorithm:

- Eliminates flaws. Thoroughly clean the surface of dirt and dust. Remove the fatty layer with a solvent. Galvanized metal fence must additionally be treated with ammonia.

- Wait for the surface to dry.

- Apply a primer. You can use a tinted coating that matches the color of the selected paint, this will give the fence a more intense color.

- Let the primer dry. When it dries, see if there are any uncovered areas. Cover them, wait for them to dry completely.

- Mix the paint well in a jar before use. If necessary, to achieve the desired shade, mix formulations, but from one manufacturer.

- Wear work clothes and personal protective equipment.

- Start dyeing. Apply one coat, wait for it to dry, then a second coat.

How to properly remove paint (LCP) from an old fence

To remove the old layer of paint, different methods are used:

- Manual, the slowest and most tedious, but the only one applicable to small fence elements. Used scrapers, emery board, metal bristle brush.

- Mechanical. A quick method, requires compliance with safety precautions. It involves the use of a grinder, sandblaster, drill with a grinding attachment.

- Chemical. Chemicals are used to dissolve old paint and remove rust.

- Thermal. A blowtorch or industrial hair dryer is used to soften the paint. The softened layer is scraped off with a scraper. You must work in a respirator, as the toxins evaporate from the molten paint.

The procedure for applying paint to an old fence

To paint an old fence:

- The paint is thoroughly mixed in a jar with any convenient device.

- Remove the old layer of paint, clean the surface.

- Apply a primer in several layers. Let dry.

- The first coat of paint is applied. For gratings and posts it is best to use a brush, for continuous coverage a roller or spray gun. Leave to dry for at least a day.

- A second coat is applied.

Solve common problems

Paint purchased in a large canister is inconvenient to use, it quickly deteriorates and thickens. It is best to pour it into a smaller container. This will make work more convenient and reduce material consumption. If thickened paint is purchased, it can be made normal by adding thinner. The main thing is not to overdo it, otherwise the composition will lose color saturation, it will be bad to go to bed.

An electric spray gun is not suitable for spraying hammer compound, it is better to use a pneumatic one for this purpose. However, an air sprayer will not withstand the application of acrylic, rubber and other dense paints, and they cannot be thinned, so you cannot do without a roller.

You need to start working outdoors when the temperature is +5 to +25 °C, the humidity does not exceed 80%. Otherwise, condensation will fall on the fence and rust will soon form.

If the fence is very rusty, it is easier to get rid of it, install a new one. If the rust has just started to spread, it is removed either with a chemical agent, according to the instructions, or mechanically, using emery paper, a grinding device or a wire brush . If after opening the box it turns out that the paint inside has formed lumps or has become covered with a dense film, the purchase will have to be discarded. It will not work well to paint the fence with such a composition.