Types of primers for liquid wallpaper and which one to choose, how to apply it yourself

Liquid wallpaper is a modern finishing material that can change interior design in a relatively short time. However, before applying such compositions, the walls must be primed without fail. Without this procedure, the material will not adhere to the surface. There are several types of primers for liquid wallpaper, which differ both in composition and characteristics.

Hardware Features

The primer is produced as a ready-to-use mixture. In some cases, these products come in powder form, which must be diluted in water before application.

The primer for such wallpaper is characterized by high viscosity, due to which the material binds microcracks, dust and small particles of dirt. After application, the mixture penetrates the surface to a depth of 1 millimeter, forming a uniform and even layer on the walls.

Primer compounds are distinguished by the following characteristics:

- prevent the formation of mold and mildew;

- form a water-repellent layer on the surface;

- hide minor flaws;

- avoid the appearance of stains on the decorative coating.

Primer mixes used to prepare the surface for liquid wallpaper application are available in the following shades:

- transparent;

- pink;

- light gray;

- White.

It is recommended to apply transparent primers under light liquid wallpaper. In other cases, the composition is selected based on the recommendations of the finish manufacturers.

A white primer is optimal when liquid wallpaper is applied to a dark surface. In such cases, the protective material allows you to see the existing defects. Also, the white floor does not allow the dark background of the base to show through the liquid wallpaper.

Due to the fact that primers have a different base, the technical characteristics of the product are also determined by the type of components used. But in each case, such materials strengthen the walls.

Varieties of primer for liquid wallpaper and recommendations for choice

In order to choose the right primer mixture, the area of application of the material must be taken into account. Based on this, such compositions are divided into the following types:

- Deep penetration primers. Ideal for treating bricks, concrete and other mineral substrates. Such soils penetrate deep into the structure of the material, binding the small particles together and strengthening the surface.

- Impregnation for wood. These products contain antiseptic agents that increase surface protection against fungi, molds and insects.

- For metals. These soils contain substances that prevent the formation of corrosion.

- Insulators and moisture modifiers. They are used for wall decoration in rooms with constant high humidity. Modifiers contain substances that prevent the negative effects of alkalis.

- Concrete contact, or primer-mastic. As the name suggests, these mixes are used for finishing concrete substrates.

When choosing a primer for liquid wallpaper, it should be borne in mind that this finishing material does not tolerate constant contact with water. Therefore, the protective base must be moisture resistant.

According to the base, primers are divided into alkyd, quartz (adhesive) and others.

Acrylic

Acrylic primers are distinguished by the following characteristics:

- good viscosity;

- fast drying;

- does not emit an unpleasant odor;

- increases adhesion;

- penetrates deep into the structure of the material;

- hides minor flaws.

Such soils are recommended for processing:

- concrete;

- cement base;

- concrete blocks;

- bricks;

- drywall.

After drying, acrylic primers create a moisture-resistant layer that prevents the formation of mold and mildew, and also increases the life of the base. Such mixtures are versatile and affordable.

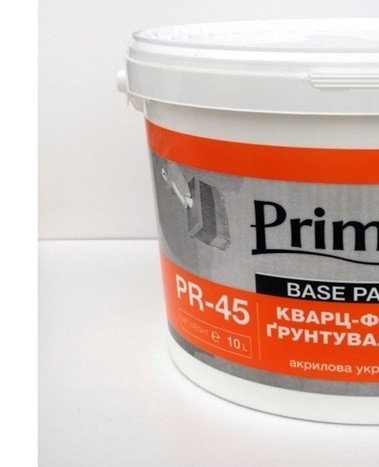

Quartz primers

Such primers, or contact with concrete, are able to penetrate deep into the structure of the material and bind small components of the base, thereby increasing the strength of the latter. These mixtures contain quartz sand, due to which, after drying, a rough layer is formed, which improves the adhesion of the finish. Thanks to this component, the risk of rolling liquid wallpaper is eliminated.

Quartz primers are recommended for applications where the finish is applied over mineral substrates. Also, this protective material is used if you plan to make colorful patterns on the walls.

Others

To prepare the base for liquid wallpaper, water repellents are used, which also have deep penetration, but, due to their special composition, provide increased protection against moisture. This material has the following characteristics:

- resistant to alkalis and salts;

- strengthens the base;

- prevents the penetration of moisture through the base;

- suitable for concrete and wooden substrates.

Alkyd primers are used for finishing metal and wood surfaces. The composition of such mixtures includes components that are distinguished by anti-corrosion and antiseptic properties. It is forbidden to apply alkyd primers on a plaster base.

Advantages and disadvantages of using

Before applying liquid wallpaper, the surface must be primed. This is due to the fact that the mixtures used in such cases differ in the following characteristics:

- increase the adhesion of liquid wallpaper to the surface;

- reduce the consumption of finishing materials;

- form a crystal lattice, which increases the life of the wallpaper;

- speed up work on the application of liquid wallpaper;

- form a protective layer against moisture;

- prevent the destruction of the base;

- eliminate microcracks.

Among the disadvantages of primers are the following:

- due to the increased viscosity, a number of mixtures dry longer, therefore, the duration of finishing work increases;

- due to improper preparation of the solution, visible stains may appear on the surface of the liquid wallpaper.

It is recommended to purchase primers of the same brand as the liquid wallpaper. In this case, maximum adhesion and protection against negative factors are achieved.

Material Cost Calculator

The online calculator allows you to calculate the approximate material consumption depending on the type of surface to be treated, the primer and other factors.

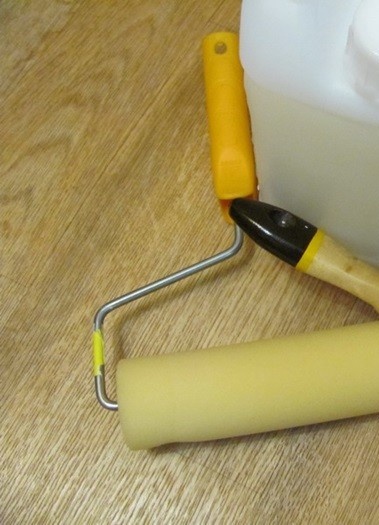

Tools needed for work

You will need brushes or rollers to apply the primer. The former are used in the following cases:

- for treatment of hard-to-reach places, joints, narrow areas and surfaces adjacent to sockets and other functional holes;

- for the application of contact concrete, because the brushes capture the particles of quartz sand better than the roller.

To transport the primer, foam rubber rollers or with a stack are used. Also, similar mixtures can be sprayed onto the surface using cartridge guns. This is convenient when a large area is required.

In addition, to prepare the surface for liquid wallpaper, it is recommended to purchase a container of soil mixture and other tools that may be needed to clean the base.

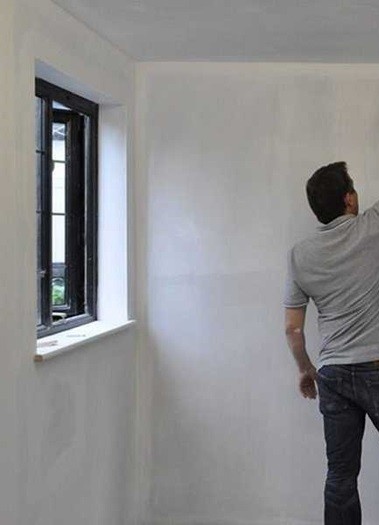

Soil application

When applying primers for liquid wallpaper with your own hands, it is recommended to first prepare the base. For this, the following activities are carried out:

- Old finishing materials are cleaned. An organic solvent may be needed to remove the paint.

- Falling plaster is removed. If necessary, the material is removed from the entire surface of the wall.

- Cracks, potholes and other flaws are putty.

- Stains are removed and the base is degreased.

- The base is cleaned of dust and other contaminants, after which it is dried.

You should also remove the furniture from the room and close off the areas that need to be protected from the primer.

When working with such mixtures, the following recommendations should be observed:

- The walls should be primed in 2-3 layers, the primer is abundantly applied to the surface.

- After applying the primer, the surface can not be treated for 12-24 hours (the period depends on the manufacturer's recommendations) so that the layer has time to acquire the specified strength.

- Primer should be applied evenly. To avoid spreading of the material, the roll should be performed several times in the same place, moving in different directions.

Concrete and plaster

It is recommended to putty concrete surfaces before priming. After that, you can apply the protective mixture in 2 thin layers. Also, before starting work, the base can be impregnated with compounds that prevent the spread of moisture.

If traces of mold are found on the surface of the concrete, first apply water-repellent and antiseptic materials, and then a primer.

When working with plaster walls, the base should be tapped to detect voids. If they are discovered, the finishing material in these areas is removed. For the application of the first coat on the plaster, it is recommended to take a concrete contact. This material is deeply penetrating. The final coat can be applied with a universal primer.

plasterboard

Drywall absorbs moisture well. Therefore, such a base should be treated with a deep-penetrating primer, applying the mixture in 2-3 layers. Before starting work, it is recommended to putty the entire drywall, and not just the joints. On the screw caps, paint or an alkyd primer should be applied.

In wood

Before finishing, wooden walls are treated with antiseptic compounds that prevent the spread of dampness, mold and mildew. In this case, it is recommended to use alkyd or acrylic primers.

If you are working with resinous wood, which over time shows resins on the surface, shellac mixtures should be used in such circumstances. Such formulations also penetrate deep into the material, providing protection against rotting and smoothing the base.

painted walls

If the old paint cannot be removed before priming the base, the surface is pre-sanded with fine sandpaper. This will roughen the base, which will increase the permeability of the material and allow the applied mixture to penetrate deeper.

Before starting work, painted walls should also be degreased. After that, you need to apply an antifungal mixture to the base, then a quartz primer.

Drying time

The drying time is indicated on the container with the primer mixture. The applied protective layer hardens completely in less than 24 hours.

Errors when working with the material

Basically, errors in priming are due to non-compliance with the technology of preparing a working solution and surface preparation. In the first case, more water is often added than recommended by the manufacturer. Due to this, the floor acquires a liquid consistency and flows from the wall.

When finishing glossy painted surfaces, the wall should be sanded with sandpaper. This layer does not allow the primer to pass through. For this reason, the wallpaper will run after applying the protective base.

Rough walls are also necessarily primed. This is explained by the fact that such a base without preliminary preparation will absorb moisture from the wallpaper, so the finishing material will not be fixed on the base.

Recommendations from the masters

If the store does not have a quartz primer, you can buy a deep-penetrating composition and mix it with fine-grained seeded sand.At the same time, protective materials prepared at home from water-based paint and PVA cannot be applied under such wallpapers.These compositions do not have the required characteristics.

It is also recommended to wait until the primer is completely dry before applying the next one.