5 types of reflective paints and how to apply them, consumption per 1m2

The advent of paints and varnishes using fluorants and phosphors has expanded the possibilities for decorating buildings, interiors, furniture, tableware and clothing. The painting of flowers and the human body with reflective paints created a new direction in art. Luminous enamels are widely used in the development of safe circulation.

Content

Reflective paint: material characteristics

A paint that has the ability to glow in the dark is called reflective/retro-reflective. The reason for the glow is due to the property of the main paint element to emit light waves. This physical phenomenon is called luminescence.

Fluorescence is a special case of luminescence. The difference is that the fluorescent glow occurs instantly under the influence of ultraviolet radiation and disappears just as instantly when dimmed.

Substances containing phosphors emit "cold" light in the dark, regardless of the influx of external energy, because they received an energy recharge during daylight hours.

On this basis, fluorescent and luminescent paints are distinguished. The composition of dyes includes substances with varying degrees of energy absorption and emission.

Composition and properties

A fluorescent coloring composition is an emulsion whose base can be:

- the water;

- urethane alkyd resin;

- polyurethane resin;

- an epoxy resin.

The second component is a fluorescent pigment made from resins capable of absorbing and emitting light.

The third element is a dye that gives the radiation a given shade of color. As a filler, rhodamine (fluorine dye), cationic or acidic pigments are used.

The use of fluorescent paint makes it possible to highlight decorative elements, to make road users more visible.

Disadvantages of fluorescent paints:

- low light;

- do not form an even, glossy finish;

- the maximum temperature threshold does not exceed 200 degrees.

The listed disadvantages reduce the scope of this type of reflective paints.

Luminescent paints stay bright for 8-24 hours. The coloring agent consists of 2 components: phosphorus and varnish.

A phosphorus is a mixture of aluminum oxide and rare earths. The glow is explained by their chemical interaction resulting from irradiation with light waves of artificial or natural origin (lighting lamps or the sun).

Thanks to additional components, light-absorbing compositions with special properties are obtained:

- moisture resistant;

- compatible with all types of varnish;

- creating an even glow of the entire painted surface.

Depending on the degree of transparency, the varnish can be colored or colorless. Colored varnishes applied to the surface look like ordinary paints in daylight. The composition based on colorless varnish becomes visible only at night. The tonal range of colorless varnishes, unlike colored varnishes, consists of 2 shades: blue or green-yellow.

The decrease in luminosity of luminescent paints is restored by "charging" from any light source in half an hour.

Adhesion to the surface is ensured by special additives for each type of material:

- for plastic - a mixture of polyurethane and inorganic resins;

- metal and glass - polyphenyl resins;

- concrete - polyurethane resins;

- fabrics, flowers, human body - an aqueous solution of acrylic paint.

Water resistance properties are provided by the introduction of acrylic varnish into the composition.

Scope

Reflective paints have a wide range of applications, as they form good adhesion to many surfaces, allowing you to provide a safe environment for humans, create an exclusive interior or image.

Fluorescent and luminescent coatings are used:

- In traffic signs on highways.

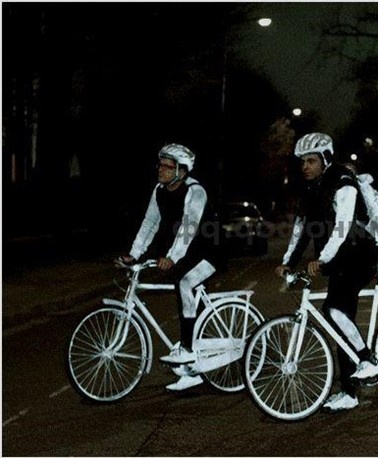

- For applying stripes and symbols to special and children's clothing.

- In decoration:

- furniture;

- dishes;

- Christmas tree decorations;

- facades of buildings;

- cars;

- public places;

- animals;

- flower sets;

- garden and personal plots.

Reflective paints have become one of the means of body art, avant-garde art, where the object of creating an image is the human body.

Varieties and recommendations for choice

Manufacturers offer consumers light-accumulating paints of four types:

- aerosols;

- enamels;

- ink;

- powder.

The variety of consistencies of use formulations expands the possibilities of using electroluminescent paints.

Aerosol

The aerosol form of reflective paint is most common in everyday life. The finished composition is sold in cans. Its application does not require special skills.

Fluorescent spray paint is used to paint:

- metal;

- in wood;

- ceramic;

- glass;

- concrete surfaces.

Advantages of spray paint:

- high strength of the coating;

- ease of use;

- fast drying.

Disadvantages of composition:

- sun exhaustion;

- compliance with safety measures during work;

- danger of high temperatures.

Aerosols are most often used to solve creative problems.

Acrylic

Reflective acrylic paints make it possible to create a decorative coating:

- on metal;

- TREE;

- glass;

- Plastic;

- textiles;

- natural stone;

- paper.

Advantages of acrylic compounds:

- high-quality adhesion;

- lack of toxicity;

- fire safety.

Defaults:

- low moisture resistance;

- destruction of the coating under the influence of detergents;

- sunburn.

In terms of quality characteristics, acrylic paints for facades are superior to paint materials for interior work.

interior enamel

Luminescent paint is used in interior decoration. The rich palette of the glow allows you to emphasize the design feature in residential premises and entertainment centers.

The coloring composition can be applied:

- on the walls;

- ceiling;

- doors;

- stage.

In this case, the manufacturer's recommendations should be taken into account, since in each version the paint should have certain characteristics in terms of wear resistance, moisture resistance.

Advantages of the coloring composition:

- scentless;

- harmful effects on the skin;

- applicable in the design of children's rooms.

Defaults:

- "Fading" of the pigment in the bright sun (fluorophore);

- delamination of the coating under the influence of moisture;

- grain.

Ink

Fluorescent ink is used in printer cartridges.

The coloring composition makes it possible to obtain:

- interior printing;

- protective coatings;

- barcodes.

To achieve a rich color spectrum, standard dyes are used as an additive.

Advantages of ink:

- use in protection against counterfeiting of financial documents;

- consumers against counterfeits;

- the opportunity to realize creative ideas.

Defaults:

- "Burnout" of the fluorophore in the bright sun;

- high price.

Glowing ink is irreplaceable in the work of forensic specialists.

Powder

Fluorescent powders are available in different colors and are used to make:

- gels;

- paints;

- varnish;

- shines.

Phosphorus can be used dry, without mixing with other components. It is also the main element of fluorescent lamps.

Advantages of luminous pigments:

- compatibility with other dyes;

- use in different forms;

- safety.

Default:

- the grain of the coating;

- discoloration with prolonged exposure to sunlight;

- does not apply as a separate component (fluorophore).

The quality of paint materials depends on the dispersion of the powder.

Application recommendations

When using reflective paints, it is necessary to observe the technological requirements for the paint.

Fluorescent coatings are additionally covered with a layer of photo-protective or waterproof varnish. Aerosol and paints are thoroughly mixed before painting.

On metal

Metal surfaces are often tinted with aerosol fluorescent compounds. The finely dispersed composition forms good adhesion to metal if the emulsion is based on epoxy or alkyd-urethane resin. Glow paint for metal should contain polyphenyl or acrylic resins.

On the clothes

For dyeing textiles, fluorescent and luminescent paints, based on a water-acrylic emulsion, are used. Release form - aerosol or canned. Glow paints for clothing should be made of acrylic.

On concrete

Concrete coatings are painted with fluorescent and luminescent compositions based on polyurethane resins.

Staining technique and number of layers

Painting any surface begins with the preparatory stage. Metal surfaces are pre-cleaned from rust. To do this, use chemical descalers, then sandpaper and degrease. If there are scratches, dents, they must be cleaned, degreased, putty and leveled with emery cloth. Undamaged areas should be dry and clean: rinsed with water and degreased.

Then a primer is applied, intended for the metal and suitable for the composition of the enamel. The aerosol is applied in 2-3 layers with a time interval of 10 minutes to an hour, depending on the air temperature.

The luminescent enamel is applied with a brush or spray gun. The staining technique does not differ from the standard. The choice of brush depends on the area and shape of the drawing. For a brighter shine, a white primer is also recommended.The number of layers depends on the thickness of the coating.

Wooden products are cleaned of the old layer of paint, irregularities are leveled with putty on the wood, sanded, dusted and degreased with an alkaline solvent. Next, the surface to be painted is primed: for fluorescent enamel - white, for luminescent - transparent.

Concrete surfaces should be thoroughly cleaned of dust, dirt, cracks should be repaired, leveled, degreased and a primer of the appropriate color should be applied.

The glass surface must be dry and clean before painting. It is recommended to apply a white primer on dark glasses. Enamel based on acrylic-polymer resins is applied in 2-3 layers with an interval of 3-4 hours at a temperature of +20 degrees.

Coating methods:

- brush;

- roll;

- buffer;

- filling;

- embedding.

- spray.

Clothes to be painted must be dry and clean. The most successful compositions of color and light are obtained on natural, synthetic and knitted fabrics of light and dark colors. Patterns are used to obtain a clear image. Enamel is applied in a single layer. After drying on the wrong side, the painted area is ironed with a hot iron.

Security measures

Personal protection measures must be observed during the manufacture of paint and paint. Varnishes and solvents in the composition of fluorescent and phosphorescent paints have a toxic effect on the human body during drying (with the exception of water-acrylic dispersions used for living organisms).

The staining process should be carried out in a well-ventilated area. Eyes and hands should be protected with goggles and gloves.The respiratory organs are protected by respirators. The paint should not be exposed to heat from radiators or direct flames.

The aerosol mixture in the can is under pressure. To avoid an explosion, the cylinder should not be heated above 50 degrees, kept in direct sunlight. Keep out of reach of children.

How long does reflective paint dry

The drying time of reflective enamel depends on the thickness of the coating, the air temperature, the emulsion base and the surface material. Water-based acrylic emulsions dry faster than epoxy and polyurethane emulsions. Concrete pavement requires a longer period for skin formation.

The minimum layer thickness is achieved using an aerosol. The drying period is 7-10 minutes at a temperature of +25 degrees. Considering the layers, the painting cycle lasts 30-45 minutes. Luminescent paint (one coat) dries for 30-60 minutes, depending on the material of the product to be painted, at a positive temperature of at least 20 degrees.

Calculation of consumption per square meter

The amount of paint needed to create a coating depends on the type and quality of the paint. Manufacturers in the instructions for use indicate for which surfaces the dye is intended and the rate of consumption. The average volume of a fluorescent enamel box is 400 milliliters. Depending on the thickness and color of the layer, the coverage area will be 80-120 square centimeters.

The consumption rate of luminescent enamel on a water-soluble base is, on average, 100 grams per 1 square meter, on a waterproof - about 250 grams / square meter, on acrylic - 10 liters / square meter. On a glass surface, 1 liter of enamel is enough to cover 12 square meters.

How to make DIY paint that reflects light

The reflective compound is easy to prepare at home.

This requires the following components:

- phosphor or fluorescent pigment;

- varnish;

- solvent.

The choice of pigment depends on the purpose for which the paint is made: to highlight or to reflect light. The quality of the coloring material affects the duration and luminosity of the luster of the painted surface.

The brand of varnish for the mixture is determined by the type of material:

- metal;

- concrete;

- Plastic;

- chipboard;

- TREE;

- the fabric.

The solvent is chosen according to the varnish.

In the manufacture of paint, an enamel or glass container is used. To obtain a homogeneous composition, you will need a mixer or a drill with a nozzle. The pigment to varnish ratio should be 1:3 (pigment: varnish). First, the pigment is poured, then the varnish is added. To obtain a more liquid consistency, pour in a solvent (no more than 1% of the total mass).

Mix well until a homogeneous composition is obtained. Phosphor and fluorescent give a single-color (bluish or yellow-green) glow. For a variety of shades, you can add a small amount of ordinary pigment to them.