Composition and types of mirror paints, application instructions and notation of marks

Mirror paint can give the surface an unusual silver, dark or golden sheen. At the same time, these materials provide corrosion protection. Mirror paints, when dry, provide superior abrasion resistance and are suitable for a wide range of surfaces including metal, wood, plastic and ceramic.

Mirror paint: composition and form of release

Paints with a mirror effect are available in spray cans, which facilitates the application of the composition to the prepared surface. The basis of this material is nitrocellulose varnish. At the production stage, this component is mixed with aluminum powder and other substances that ensure an even distribution of the composition on the working surface.

Nitrocellulose varnish is responsible for creating a strong film. The mirror effect of this painting is ensured by the aluminum powder.

The final result, which is obtained after drying this material, depends on the characteristics of the additional components.That is, the additives are responsible for ensuring that the base varnish lies evenly on the surface, and the aluminum powder forms a reflective layer.

Scope

Mirror effect paint is suitable for:

- metals;

- ceramic;

- Plastic;

- concrete;

- drink;

- glass.

In this regard, the field of application of this dye is wide. But most often such a coating is used for processing body parts, mirror housings, etc. Also, the material can be used for painting walls in interiors, decorative structures and other products.

Advantages and disadvantages of using

The benefits of a mirror effect tint are:

- ease of application;

- the ability to resist corrosion and mechanical stress;

- high adhesion;

- wide range of applications, not limited to one material;

- dries quickly;

- does not impose strict requirements on storage conditions.

Among the disadvantages of such a dye, the following can be distinguished:

- the work plan must be carefully prepared before application;

- painting work should not be carried out in a room where dust particles are present in the air;

- The mirror spray is suitable for painting small areas.

Also, this should include the fact that colors often differ in tonal saturation. That is, after surface treatment with two or more cartridges, one part of the material may be darker or lighter than the other. Therefore, it is recommended to purchase only one brand of mirror paint.

Varieties

Regardless of the type of manufacturer, each mirror paint is available as a one-component or two-component composition.

Monocomponent

One-component formulations are convenient because they are immediately ready for use: it is enough to shake the canister, after which the material can be applied to the surface. Some manufacturers package these paints in jars.

One-component compositions are mainly used for the treatment of insignificant surface surfaces. This is due to the fact that this type of paint is not able to recreate a full-fledged mirror effect: the difference in gloss compared to polished metal becomes immediately noticeable.

One-component aerosols are difficult to apply. When working with such paint, it is necessary to take into account many nuances, on which the result depends. The disadvantages of such compositions include the fact that these materials dry quickly. Due to this, the paint does not have time to penetrate the structure of the surface, so the dried film peels off early and does not tolerate mechanical stress.

In addition, single-component aerosols are characterized by high consumption.

Bi-component

Two-component formulations differ from the previous ones in that they are produced mainly in banks. These products are based on acrylic or epoxy resin. The disadvantages of two-component formulations include the fact that the material must be mixed with a hardener before application. At the end of the work, the dried film must be painted over with varnish.

At the same time, two-component compositions are able to recreate a mirror-like shine on the surface, comparable to polished metal. The dried coating is characterized by increased resistance to mechanical stress and heat treatment. In addition, two-component formulations are slowly consumed.

Difference in shades

The type of shade of mirror paint is determined depending on the type of component with which the base varnish is mixed. Most often, aluminum powder is used for these materials, which gives the surface a silver color. There are also compositions of other shades on the market:

- the association of the varnish and the yellow metal makes it possible to obtain a golden dye;

- the mixture of aluminum powder and translucent black pigment produces a dark finish.

Some paint manufacturers offer a tinting service. In this case, the final shade is determined according to the type of pigment used.

Step by step instructions

The main difficulty when painting with mirror compounds is that the surface must be carefully prepared. In addition, these materials do not tolerate contact with dust and other contaminants. If small particles get into the material, noticeable irregularities will remain after drying on the surface.

In this regard, work on painting materials with mirror effect compositions should be carried out in rooms with functional ventilation, but without drafts. To finish the surface with such compounds, you will need a spray gun. Depending on the type of material to be painted, it is also necessary to prepare a plane, a hair dryer, a spatula and other tools.

Surface preparation

Regardless of where the dye is applied, the surface should be rinsed and dried before starting the procedure. In the next step, the following work is carried out:

- traces of rust or scale are removed (if the metal is painted);

- the old coating is removed (this applies to all surfaces, including plastic and plaster walls);

- the surface is treated with a solvent to remove traces of grease;

- the surface is leveled with putty (if the walls are painted).

When working with wood, it is recommended to level the material with emery paper or a grinder, gradually reducing the grain size. Plastic, unlike other materials, is damaged by old paint. In this case, coarse sandpaper is also used to level the surface.

At the end of the work, it is recommended to rinse the material again. Finally, the surface is primed with a thin layer. If stains occur, the applied material should be removed and this procedure should be repeated. If this is not done, after staining visible defects will remain on the surface.

Application technique

The technique for applying mirror paint is determined taking into account the type of material being processed. The following diagram applies to plastic:

- The surface is painted black.

- The material is polished to a mirror finish and treated with alcohol.

- Painted plastic is heated with a heat gun.

- The mirror paint is applied to the heated surface which, after drying, is repolished.

Also, the plastic can be painted according to the following scheme:

- The plastic is painted black, dried and varnished.

- The surface is dried again and polished.

- Mirror paint is applied to the material under high pressure and sprayed in a thin layer. This procedure can be carried out several times, depending on the effect that needs to be recreated on the surface.

- The material is placed in a special dryer heated to 60 degrees. Here the product should be kept for one hour.

- Three layers of fixing varnish are applied to the surface at intervals of 20 and 25 minutes, respectively.

- The plastic is dried and polished.

It is important that during the painting process each layer of the applied composition (paint and varnish) is completely dry. Otherwise, the risk of smudging and damage to the plastic remains.

When working with metal, they adhere to a different pattern. This approach is mainly used when painting a car body with high gloss compounds. Metal processing is carried out according to the following algorithm:

- The material is cleaned, dried and polished. As part of these procedures, it is necessary to remove traces of rust and other defects, including irregularities, using sandpaper or a grinder.

- The metal is primed and dried.

- A coat of black paint is applied to the body metal, which is polished after drying.

- Using a spray gun, a thin layer of mirror paint is applied to the metal and dried. This step can be repeated as many times as needed to achieve the desired effect.

- Dried paint is fixed with varnish.

Do not apply mirror paint with a brush or roller as this will cause smudging.

Drying time

Drying time depends on environmental conditions. At a temperature of +20 degrees, the paint acquires sufficient strength within 24 hours after processing.

Unusual effects and ways to design them

In addition to tinting, mirror paints are sometimes mixed during the production process with additional components, due to which the material becomes transparent after drying. However, with temperature fluctuations (increase or decrease), due to the peculiarities of these substances, the dried material begins to acquire a given shade.

This type of dyes are more often used in finishing car bodies. These materials are divided into 2 types: some are able to become transparent repeatedly when exposed to temperature, others - once.

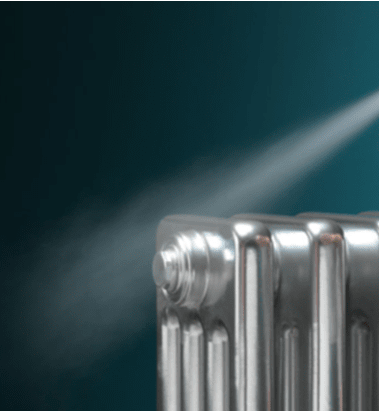

There are also mirror effect stains, which contain substances that give the surface a matte shine. These materials are mainly used for finishing plumbing fixtures or furniture fittings.

Ranking of the best mirror paints

The best mirror paints include the following brands:

- Peak power. The compositions of this brand belong to the budget group: one spray can costs about 350 rubles. The material is produced ready for use and is suitable for processing small areas.

- Bosnian Chrome. This company produces inexpensive mirror sprays that are used for processing small objects.To give a lasting effect, it is recommended to apply varnish after staining.

- Chrome effect. The best dyes with a mirror shine are produced under this brand. Chrome Effect is more expensive than the above products. This material is suitable for painting cars.

There are other manufacturers of mirror paints on the market. But those above are more popular.