Types of primers for polystyrene and rating of the best brands, rules of application

Recently, the coating of exterior surfaces of buildings has become increasingly popular. It helps to improve the decorative properties of the coating and increase the heat-saving characteristics of the structure. To achieve high-quality results, use a special mousse primer. It provides reliable protection of the surface from the negative influence of external factors.

Foam primer: composition and characteristics

Facade polystyrene foam has a fairly dense structure and does not absorb moisture. According to building codes, it must be primed. Thanks to this, it is possible to increase the adhesion of the treated surface with the applied plaster and glue. The soil also helps to reduce water absorption from the porous substrate.

Performing foam priming before using plaster is considered an important technological operation.With its help, it is possible to increase the adhesion of finishing mortar mixtures and level the layers. The primer helps absorb excess material when grouting plaster.

Many primers contain germicidal ingredients. After treating the walls, they reduce the risk of mold and mildew.

In terms of composition, alkyd, polyvinylacetate, phenolic primers are distinguished. These are also glyphtal, perchlorovinyl, acrylic. The composition should be selected taking into account the performance characteristics of the plaster or tile mortar. It is also influenced by the application domain.

Purpose and scope

According to their technical characteristics, primer mixtures are divided into means for increasing the strength of the coating and the adhesion of the base with finishing materials. Depending on this, their purpose is also different:

- Reinforcing primers should be used for porous surfaces. The main advantage of such solutions is considered to be a large depth of penetration. It reaches 100 millimeters. In addition, after the layer dries, a high-strength protective film appears on the walls.

- An adhesive primer mixture is used as an intermediate layer, which improves the quality parameters of the finish. Such a primer should be used before applying plaster and decorative types of coating.

Advantages and disadvantages of using a primer under the foam

The floor for penoplex has many advantages. The main advantages are:

- increase the adhesion of the base with finishing materials;

- ease of use;

- increased heat-saving properties;

- prevention of mold and mildew formation.

At the same time, the material is also distinguished by some disadvantages:

- the need for careful preparation of the surface for the application of the material;

- the need for a good choice of composition;

- high labor intensity.

Soil types and selection recommendations

For painting

Before painting the moss, experts recommend treating it first with soil. To do this, you must do the following:

- Remove excess objects from the coating surface.

- Clean the surface.

- Remove dust and foam fragments.

- Apply the primer to the prepared surface. The number of layers is determined by the quality of expanded polystyrene and the characteristics of the planned paint.

Due to strict adherence to the sequence of work, it is possible to preserve the technical indicators of the foam and ensure its protection from the influence of external factors.

Under cast

Today, plastering on polystyrene foam panels is not uncommon. In addition to decorative properties, this method allows you to additionally insulate surfaces. In this case, land use is of great importance. The durability of decorative and textured plaster depends on its application.

In this case, a textured material, such as bark beetle, should be applied over a primer containing a quartz filler. Experienced craftsmen advise using the composition Ceresit CT 16. This is a polymer acrylic mass, which contains grains of quartz sand. If coloring with a facade dye is planned, it is worth using Ceresit CT 17 universal primer.

liquid glass

When dyeing polystyrene, it is important to choose the right composition. It must be elastic and resistant to temperature fluctuations and precipitation. Modern paintings fully meet these requirements.However, almost all of them contain aggressive substances that cause the destruction of the foam structure.

To avoid problems, it is worth using protective substances. For this purpose, liquid glass is usually used. It is a solution of sodium or potassium silicate. Due to the high tension of the foam fragments, a reliable obstacle to the penetration of liquid glass into the structure is obtained. As a result, it is possible to obtain a high-quality protective film.

To make liquid glass more elastic, it is recommended to add a primer to it, rather than water. Moreover, it must be universal.

Ranking of the best brands

For application on polystyrene, it is allowed to use the following types of primer mixtures:

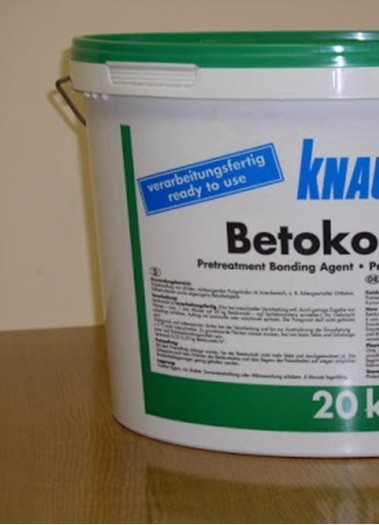

- Knauf Betokontakt. This solution does not penetrate deeply into the substrate. It mainly permeates the surface to a maximum depth of 4 to 5 millimeters. At the same time, the composition provides high adhesion of the porous surface. After the liquid dries, a rough coating forms. Even a dry finish clings to it perfectly.

- Eskaro Aquastop Professional. This product has moisture insulating properties. It is distinguished by its concentrated composition. The penetration depth is 6 to 10 millimeters. The undoubted advantage of the mixture is considered quick drying - it takes no more than 1-2 hours.

- "Optimist G 103". This product is considered environmentally friendly. The solution is suitable for use on a variety of surfaces, and foam is no exception. After drying, the agent reliably protects the coating from fungus, bacteria and mold. It takes about 2 hours to dry.

How to properly prime for waterproofing

In order for the primer to give the desired results, it is important to follow the application instructions carefully. In this case, it is necessary to take into account many nuances.

Soil consumption and features of the preparation of the solution

Most often, the consumption of potting soil is indicated on the package. This parameter is directly affected by the composition of the substance:

- Acrylic primers - their consumption is 80-120 grams per square meter.

- Deep penetration primers - 50-150 grams of the mixture is needed per 1 square meter.

- Quartz-filled formulations - you need to use 150-200 grams of the mixture per square meter.

Taking into account the standard values, it is possible to easily determine the amount of soil needed for work. To prepare the composition for application, it must be thoroughly mixed. If the mixture is too thick, it is recommended to add water to it. In this case, it is worth focusing on the instructions.

Tools required

To carry out the work, it is recommended to prepare the following items:

- Polyurethane floats.

- Mixing buckets.

- Construction mixer with a metal whisk.

- Master okay.

- Mesh or grinding block.

- A set of paint spatulas of different widths.

- Ruler with level.

You will also need a special adhesive, a dry plaster mixture, a primer and a substance for finishing the decoration. For finishing the foam, it is recommended to use special plaster compounds. They are mineral and acrylic.

Surface preparation and leveling

The coating should be applied on a flat surface. To assess whether the expanded polystyrene plates are fixed evenly, it is recommended to apply a plaster ruler to the base. It is also allowed to use a wide spatula.If the joints of adjacent slabs are at the same level, the surface is considered flat.

It is recommended to pay particular attention to the joints between the plates. They must be well sealed. In this case, the excess mounting glue must be cut off.

To improve the adhesion of the leveling layer to the foam, it must be processed with a needle roller. In this case, the plaster will penetrate deep into the pores.

Mesh Installation and Priming Technique

To prime the surface, it is recommended to proceed as follows:

- Prepare a primer mixture. To do this, mix well. If the consistency is too thick, you can add a little water following the instructions.

- Apply the primer with a wide paintbrush or a regular flat paintbrush. It is also allowed to use a sprayer or paint roller. After the work is finished, the tools should be cleaned well.

- After the floor is completely dry, the surface will become more resistant to the influence of mechanical factors.

To improve the adhesion of the plaster on the smooth foam plates, it is recommended to use a reinforcing mesh of polyester fiberglass. To fix this, you can use the following methods:

- Attach a mesh reinforcement strip to the foam board. Its length should be 1-1.5 meters. Above with a wide spatula it is necessary to apply an adhesive composition and level it on the surface of the reinforcing layer. The mesh should be immersed in the applied solution and, so to speak, immersed in the glue.

- Spread the adhesive on the board using a spatula and spread it evenly over the surface. Lay strips of masking net on fresh mortar and smooth with a layer of glue.

When comparing these methods, the second is considered the preferred option. When applied under the reinforcing mesh, voids are not formed without glue. As a result, the fixation is much stronger.

Coat drying time

Many factors affect the drying time of the floor. These include the type of mixture and the conditions for carrying out the work. The duration can vary from 30 minutes to 12 hours.

Continuation of work

After fixing the reinforcing mesh, it must be covered with a prepared adhesive, smoothed with a plastic trowel and sanded with a special mesh. At the same time, it is allowed to start this procedure after incomplete drying of the composition.

Some masters carry out this procedure only the next day - after the solution is completely dry. However, scrubbing a dry coating is very problematic. In this case, it is necessary to constantly wet the surface with water and apply a lot of effort when grinding.

At the final stage, a decorative finish is performed.For exterior work, special facade plasters have been invented. They are resistant to temperature fluctuations and weather changes. The properties of plaster are influenced by the type of binder and the presence of additional ingredients. The most commonly used are mineral, acrylic and silicate plasters.

To perform the procedure, you must do the following:

- Prepare the working solution. This applies to the mineral mixture. Thoroughly mix the finished composition.

- Apply plaster. At this stage, it is necessary to plan the finishing structure. The thickness of the layer should not exceed 40 millimeters. The next layer can only be applied after the previous one has dried.

- Do the grouting. This is done after the layer is half dry.To form an unusual structure of the facade, it is worth using a special roller.

Recommendations from the masters

When priming foam, you must adhere to the following rules:

- after the end of the procedure, sand the spots;

- protective equipment must be applied to the fiberglass mesh;

- when using pigments, you must first do a trial batch.

The use of a foam primer helps to improve the adhesion of the base to finishing materials and protect the coating from the negative influence of external factors. In this case, it is important to strictly follow the instructions for use of the substance.