How to paint a brazier and the 7 best brands, how to apply it correctly

When the question arises of how to paint a metal brazier, it is recommended to pay attention to a special type of painting materials called thermal paint. Not all paints are suitable for painting a surface that is heated during operation. Manufacturers produce special heat-resistant paint materials that can withstand high temperatures, do not ignite and change color.

Grill Painting Functions

With the help of paints and varnishes (LKM), metal barbecues are given a more decorative look and the desired color. To paint these metal objects, several types of special paints are used (heat-resistant, heat-resistant, fire-resistant).

Ordinary compositions for coloring barbecues are not used. These metal objects become very hot during operation. Therefore, for their painting, special thermal paints are chosen, which are able to withstand high temperatures and not ignite.

Braziers are usually made of iron.Since the metal is susceptible to corrosion, the compounds must also protect the surface from rust formation. With the help of paint, they try to extend the service life of a metal product. Reasons to paint the barbecue:

- to give a more decorative look;

- for protection against precipitation (when used outdoors);

- to protect against rust;

- to protect the barbecue from deformation during heating;

- facilitate the management of the subject;

- extend the operating period.

As a rule, thermal paint for barbecues is silver, gray or black. Some manufacturers produce compositions of different shades for coloring heating objects.

Benefits of using heat resistant paint

Heat-resistant paints are used for painting objects heated during operation. Such paint materials are able to withstand periodic temperature increases while not changing their decorative qualities (does not fade, crack, change color).

Thermal paints are generally made up of resins, metal powders (zinc or aluminum), additives and pigments. Metal is used in the composition of certain paint materials to give them thermal resistance and protection against corrosion. Resins improve adhesion to the surface of the object to be painted and also give elasticity to the coating.

Benefits of using heat resistant paint:

- the coating can withstand temperature rise up to + 400 ... + 800 ° C and above;

- after drying, a strong, elastic and hard film is formed;

- a film layer protects the metal from the formation of rust;

- painting gives the surface a decorative look;

- the coating protects the metal from destruction;

- LMC does not turn on;

- the coating prolongs the life of the object.

The thermal paint is applied to a dry and clean external surface. After drying, the paint layer must be heated. This procedure starts the coating curing process. The film becomes strong and heat resistant.

The inside of barbecues can only be painted with refractory compounds. Such paint materials can withstand heating up to +1000 ° C and above.

Appropriate dyes

To paint barbecues, paints and varnishes based on resins, metal powders (aluminum or zinc), pigments, various additives and solvents are used. Each type of paint material has its own advantages and disadvantages.

Based on alkyd resins

Heat-resistant compounds based on alkyd resins can withstand temperatures up to +600°C. Creates a matte finish. Available in the form of liquid paints in spray cans or in spray cans.

Silicone

Heat-resistant compounds based on silicone resins can withstand heating up to +500 degrees and more. The coating does not soften with increasing temperature. The film formed on the surface repels water.

organosilicon

Heat-resistant organosilicon paint materials withstand +700 ° C and above. The composition of such paints usually includes resins, aluminum (zinc) powder.Organosilicon paints and varnishes are one-component and two-component. Marked with the letters "KO".

On acrylic epoxy paint

Heat-resistant compounds based on acrylics, epoxy resins and powder (zinc, aluminum) can withstand heating up to +400°C and more. They form a strong film that resists mechanical stress.

Popular manufacturers

Thermal paints for painting barbecues are produced by various manufacturers. For painting metal products, as a rule, paints based on resins and metal powders (zinc or aluminum) are used. The metal used in the composition of certain paint materials creates an anti-corrosion protection on the surface.

Tikkurila

Products of the Tikkurila company can withstand +400 degrees and more. Thermal paints are produced on the basis of alkyd, silicone and other resins. Various additives, pigments, as well as metal powders (zinc, aluminum) are introduced into paint materials.

Certa

Thermal paints of the Certa brand are distinguished by a wide range of colors. They create a film on the surface which can be heated up to +1200°C.The company produces heat-resistant paints based on organosilicon and other resins.

Hansa

Hansa brand thermal paints (+800 degrees Celsius) are made on the basis of resins and metal powder (zinc), as well as various additives and pigments.

Hammerite

Hammerite produces a wide range of paints for painting metal products and objects. Many types of paint materials are applied directly to rust. The assortment of this company includes thermal paints that can withstand + 80 ... + 120 ° C and more.

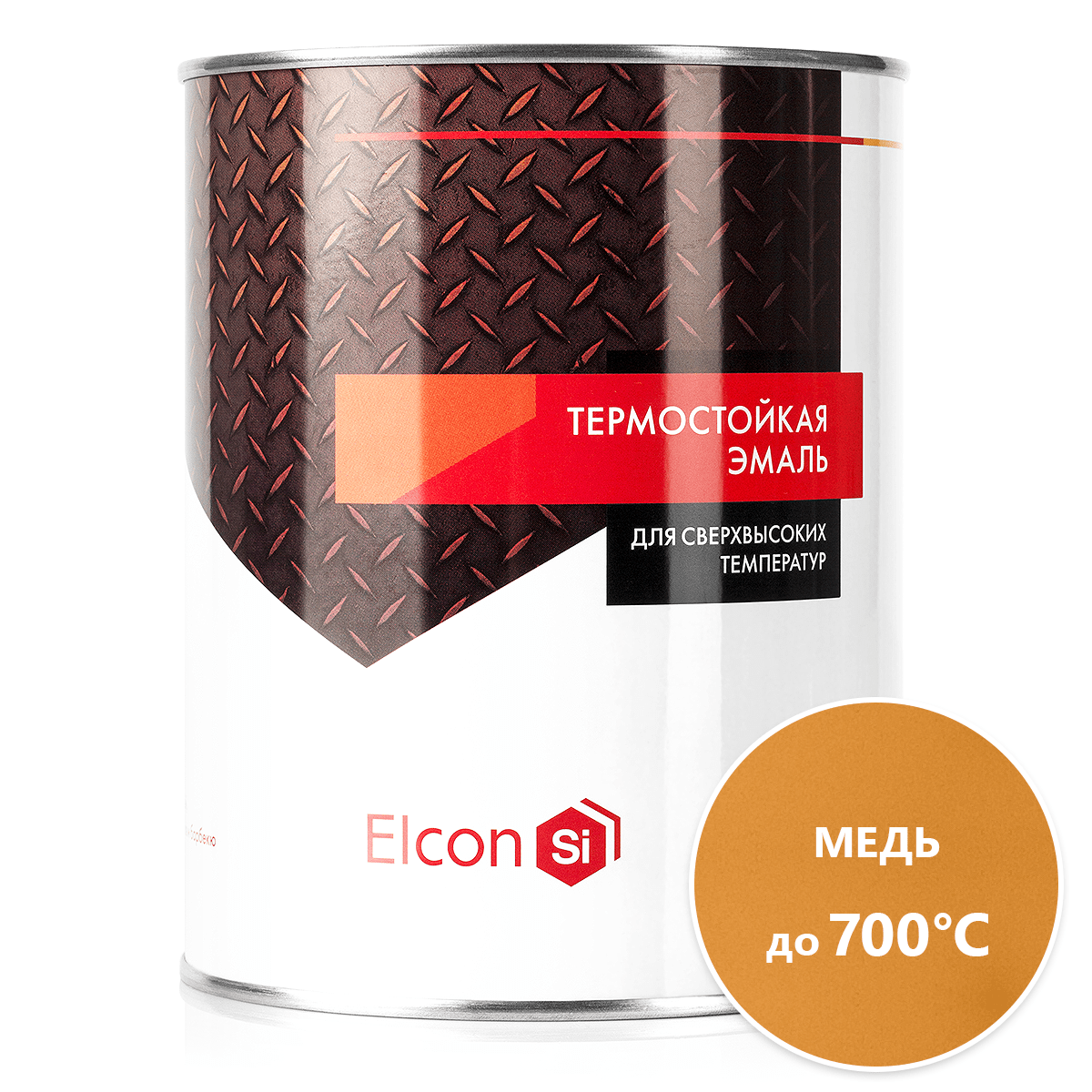

Elkon

When using heat-resistant enamels of the Elkon brand (+1200 ° C), the surface to be painted does not require prior priming.

Cheer

Heat-resistant enamels of the Kudo brand are made on the basis of resins (organosilicon) of various colors. They have different packaging (made in the form of aerosol cans).

Dali

Heat-resistant glazes of the Dali brand based on resins (organosilicon) can withstand temperatures up to +600 degrees and above. They are used for the protective and decorative painting of barbecues. Can be applied to cast iron, steel.

Preparatory work

Thermal paints are applied only on a clean and dry surface. It is recommended to remove the old coating layer before applying heat-resistant paints and varnishes. The smooth metal surface is sanded before painting. The base with rust is subjected to sandblasting, shot-blasting. Traces of metal corrosion (down to the smallest particles) are removed with sandpaper or a special tool (rust converter).

After cleaning, it is recommended to degrease the surface (with acetone, solvent, xylene, solvent), dry well.

How to paint correctly

The grill is painted at an air temperature of +10 degrees and above. The paint is applied on a perfectly dry and clean support. To apply paint materials, brushes, rollers, paint sprayers are used. Staining is done in 2-3 layers. During painting, take care to respect the interlayer drying interval (at least 1 hour). The painted surface is subjected to heat treatment for 1-2 hours (the grill is heated to 200 degrees).

Important subtleties

Thermal paint is applied to the surface in a thin layer.To dilute paints and varnishes, use the thinners specified by the manufacturer in the instructions. After applying the paint materials, wait for the paint to dry completely. Do not paint sticky or wet surfaces. A coat of paint applied to a wet base can swell.

Prevent rust

Rust converters are used to prevent corrosion of metals. These chemicals (primers) are applied before painting. Converters eliminate or transform rust into a protective anti-corrosion film.