How to repair different parts of the zipper and the tools you need with your own hands

Zippers are the most popular fasteners widely used in clothing, footwear, equipment and accessories. Manufacturers offer zippers made of metal, plastic, different in shape, type and method of connection. Mechanical stresses, manufacturing defects are at the origin of the failure of the fixing. How to repair a zipper yourself?

Reasons for the malfunction of the lock

Malfunctions in the operation of the zipper should be sought in its design features.

Lightning Elements:

- connections;

- lock connecting links (slider/dog/slider);

- lock suspension (puller/tongue);

- bottom stop;

- upper limiter;

- braid.

On two textile belts, metal or plastic links in the form of teeth or twisted rings are fixed in a checkerboard pattern. The connection/disconnection is carried out using a lock which slides freely along the ribbons. The width of the handle and the shape of the slider allow you to fix a link between two opposite links.

There are two grooves in the front of the slider. The width of each corresponds to the length of the pin. At the back, the grooves merge into one, equal to the width of the fastener. When securing, the links are captured by the slider and form a tight grip in the narrow channel. During unbuttoning, the reverse process occurs: the bifurcation of the canal uncouples the teeth.

Limiters determine the length of the tether, stop the movement of the dog. The purpose of the puller is to provide convenient use of the lock.

Failure of any of the listed items affects the function of the fastener. The main reasons for violations are the result of negligence, normal wear and tear, workmanship of poor quality materials, manufacturing defects.

The dog has moved

This type of failure occurs on a split model. The first reason is the divergence of the flanks of the shoe, guides and compressing the teeth. The second is the separation of the lower/upper tape stopper.

Runner spawns in a location

Sliding the slider on one side of the zipper occurs:

- due to the inclination of the links, which must be captured by the slider in parallel;

- uneven edge wear, leading to weakening of compression;

- break / loss of link.

Defects are typical for all types of fasteners.

The clasp is open or the slider gets stuck

The zipper ceases to be a clasp: the hammer connects the teeth, but they immediately move apart, or there is an obstacle to the movement of the slider. In the first case, the breakdown is due to wear of the grooves, which does not create the required pressure. The second reason is the "sticking" of the lining between the teeth. The third is the loss of teeth, which interferes with the sliding of the slider.

The dog is not fixed

The deformation of the sole leads to a deterioration of the fixation of the skate in the intermediate position.

Incorrect storage

Items with a zipper should not bend too much so as not to deform the teeth. The zipped storage protects the links from contamination by villi, grains of sand.

Weather

Metal locks without a protective strip will rust quickly when exposed to moisture.

Bad size

A dog whose size does not correspond to the teeth will not be able to chain them: too small will not slip, too large will not grip.

Types of lightning

Fasteners are classified according to the method of separation: total or partial. The use of one type or another depends on the functional purpose of the thing.

Unilateral

Detachable models are one-sided views. When detached, the fastener diverges into 2 sides, the slider remains on one of the halves. The design feature of split zippers is the presence of a pin and a split stopper with a sleeve. The connection is made using a pin which passes through the holes of the slider and is fixed in the cap. When disconnected, the pin remains on one half of the strip, the slider on the other.Single slot views can have 1 or 2 locks. Two-way zippers have a more massive stopper and a long pin. Such fasteners are used on outdoor sportswear.

Double sided

On double-sided fasteners, the ratchet always connects the two halves: in the buttoned and unbuttoned position, which is typical of one-piece models with one or two locks. These zippers are used on shoes, bags, clothes (pants, skirts, dresses). The clasps have free strap edges. Bottom - end point of unbuttoning, they are connected by a common stopper. Top - the end point of the zipper - two (for each half of the zipper).

This type includes a detachable double-sided zipper with two locks, in which the detachment occurs not at the edges, but in the middle or from the middle to the edges. Two sliders act as a stop in the central part of the attachment.

Types

The types of zippers are determined by the functional characteristics of the locks: presence, absence of protection against spontaneous unlocking.

The castles are:

- automatic locking, A / L - automatic;

- pin lock, P / L - semi-automatic;

- not lockable, N/- haberdashery.

The use of locks depends on the type of fastening.

Auto

The A/L lock has a slider with a mechanism that locks the links and prevents them from diverging, regardless of the hanging position. The brakes are spring-loaded spikes located inside the skate. Disengagement occurs when a pulling force is applied to the remote. Automatic locks are used on split models with large teeth.

Semi-automatic

The P/L lock has a slider with spikes located in the key fob. When the tongue is lowered, the pins penetrate between the teeth and interfere with the dog's movement. To open the zipper, you must lift the puller. Semi-automatic devices are used in split types.

Haberdashery

Clasp with N/L lock: the slider has no automatic machine and stopper, it moves without fastening. These cursors are installed on permanent connections.

what do the numbers mean

The numbers refer to the dimensions of the teeth: they indicate the width in millimeters when the zipper is closed. The marking is applied to the cursor from the inside. The shape of the top of the tongue depends on the type of links.

Metal teeth are 3, 5, 8, 10 millimeters, the top of the slider has a triangular shape. Molded plastic teeth (tractor) - 3, 5.7, 8, 10 millimeters, oval or cloverleaf slider. Twisted plastic links (spiral) - 2, 3, 4, 5, 6, 7, 9, 10 millimeters, the slider looks like an oval. The longer the teeth, the stronger the pull and the tensile bond.

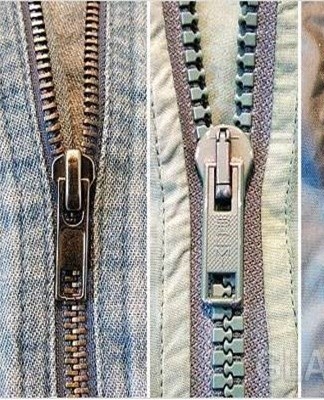

Metal clasps

Metal zipper teeth are made from flat brass or nickel wire. The shape of the links is asymmetrical: on one side there is a protrusion, on the other - a depression. The connection with the tape is double-sided. The grip quality is high, but due to the crooked teeth the slider can "stick".

tractor lightning

The clasp consists of wide plastic teeth secured on one side with a dense webbing. The shape of the links resembles a caterpillar track. The advantage of such a zipper is the durability of the links. But depending on the method of attachment, it loses resistance to metal and twist ties.

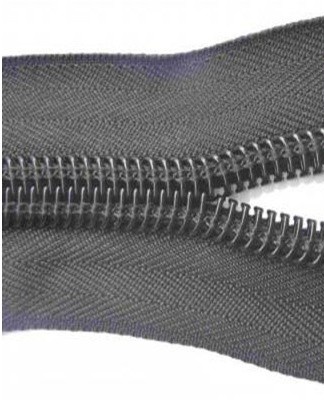

twist clasps

The zipper is made of a coiled line.The fiber is wrapped or sewn onto the braid. The adhesion is formed by the protrusions of the fibers on both sides.

Letter designations

On the sliders, next to the number markings, there may be letters. Brief information about the functional characteristics of the bindings is encoded in the letters.

"A"

The symbol means that it is a permanent connection.

"B"

The letter code means it is a detachable snake with a single lock.

"VS"

The "C" sign is a split model with two locks.

"D"

The clasp marked "D" has 2 slots and 2 locks.

"H"

Zipper marked "H" one-piece, with two locks.

"I"

The letter "L" corresponds to a one-piece fastener with a single lock.

"X"

Identifying feature: cast in one piece, with two sliders.

What you need to replace

To put on a new fastener, you need to choose a similar one with the help of tools and auxiliary materials.

New slider

When choosing a zipper, pay attention to the dog. The functionality of the zipper depends on its qualities. If the fastener is changed on the shoes, the slider must have a thickened base. For outerwear, backpacks, tents, a strong metal padlock is required. A convenient tab is needed to use the zipper with gloves, for children's clothing. The broken cursor is replaced by a similar cursor. The need for replacement arises when cracks appear in the sole, irreparable breakage of the extractor.

For each type of zippers, select their own slider, as they have the design features of the sole.

The shape of the sole of the metal teeth sliders looks like the letter "U" at the bottom and top. For dogs with spiral binding, the bottom of the sole is straight.The padlocks have a 3 millimeter thick reinforced sole. Tractor locks are structurally similar to metal locks. The pads are made of metal or plastic. The plastic ones are used for narrow synthetic ties. Metallics are used for all types of zippers.

Small scissors, blade

Short scissors, a razor blade are needed to gently tear the seams connecting the tape to the lining and unfasten the worn zipper.

needle and thread

A needle of medium thickness and threads of the color of the braid are needed for sewing the fastener, fixing the stopper, reinforcing the connecting seams with the lining.

Pliers, pliers or cutting pliers

The tools are used to adjust the edges of the slider after sewing in the zipper if it walks too freely. With their help, the side, rear and entry clearances at the slider are reduced.

Knife (screwdriver)

A knife or screwdriver will be useful to open the edges of the slider if they are too tight, and to bend the stops.

clay moment

You will need quick-drying glue to reinforce the tape where it joins the cork.

How to replace. Sequencing

Lightning replacement step by step:

- use scissors and a blade to rip the seams;

- pull the clasp;

- remove the remnants of the thread;

- insert a zipper;

- bait the braid to the liner;

- try castle work;

- sew by hand or typewriter.

You will need glue to secure the bottom of the split zipper.

If the stopper of a removable zipper with a place for a pin has come off the fastener, to put it in place you must:

- drill a through hole;

- put in its original place on superglue;

- rivet.

As a result of the repair, the functions of the limiter will be restored. If the zipper teeth are broken. Instead of tearing the zipper, a new zipper is alternately hemmed at the bottom.

Lock and different types of lightning

According to the method of opening zippers, they are detachable and one-piece, according to the number of locks - one, two locks.

Metal clasp

A metal-toothed zipper opens from top to bottom, separating the edges with a movable pin. At the bottom of the clasp there is a one-sided massive stopper with a slot for two pins: movable and fixed. When fixing, the movable pin is fixed in the socket, it is removed for loosening. There may be 1 or 2 zippers on the zippers. At a single-lock detachable zipper, the lock detaches from the top. Two locks are separated by two sliders on both sides.

A play

The one-piece clasp has a bottom stop with fixed pins.

One-piece zippers detach according to the number of locks:

- with a slider - up and down;

- with two - from the center to the edges;

- with two - from the edge to the center.

One-piece zippers can be spiral, tractor, metal.

What to do if lightning diverges

First of all, you need to determine the reason why the teeth do not hold the handle. Depending on the defect, repairs are carried out.

The castle is open

Poor grip is caused by wear on the edges of the pad. Using pliers or pliers, press the slider from the front and sides. Repairable metal dogs. No great effort is required to avoid deforming the mechanism. Handling is done with an unzipped zipper.

Break the dog

A slider becomes unusable if it has a crack in the sole, wear on the edges and grooves when pressed does not give the desired effect when compressed. The slider is selected depending on the size and type of pin, the purpose of the thing. For example, for a detachable "tractor" zipper on outerwear, you will need a #7 metal slider; for a spiral zipper on shoes - a reinforced plastic lock No. 6, 7.

To replace the dog you need:

- remove the brackets at the bottom with an awl/screwdriver/knife;

- drag the slider;

- put a new slider at the ends of the braid;

- push and tie at dog's length;

- put the brackets in place.

At the end of the repair, check the operation of the lock.

Tongue fell out

You will need to put in a new slider if the connection with the slider bursts with the tab. But if the suspension breaks, and the ring is kept, it is enough to change only the tongue: insert a homemade one or remove it from the old zipper.

lightning broke

The torn braid is sewn in its original place by hand.

Basic break

The zipper will diverge at the bottom if the dividing zipper with a slot for a pin has come loose. To set it up, you must:

- drill a through hole;

- put in its original place on superglue;

- rivet.

In the event of failure of the plastic stops of the one-piece zipper, it is necessary to remove the damaged parts. Saturate the braid with Moment glue, replace the caps and pressurize until dry.The second reason for base lightning failure is fabric wear. To restore it, use manicure varnish.The braid is shaped and soaked twice in nail polish. As an impregnation, you can use rubber glue and Moment.

The tooth of the lock is broken

The fallen links break the attachment of the neighboring teeth, which leads to the divergence of the lightning.

The recovery method depends on the type of link:

- Breaking the spiral. To restore it, you will need the same section of the fishing line. A piece of fishing line is pulled over the defect site several times. The diameter of the winding should match the diameter of the remaining links. Inside the braid, you need to tie a small knot and solder it on fire from a match or lighter.

- Loss of a metal tooth. Repair the zipper if similar scratches are found. Dimensions and shape must be identical. The links are separated from the old fastener, put in empty places and tightened with pliers. Lay the zipper out on a flat spot and tap the ties with a hammer. Check the attachment and operation of the slider.

Seizes

Obviously, an entire zipper can be closed and unfastened tightly, which is often the case with newer products. Various lubricants are used to facilitate the sliding of the wheel on the toothed belt.

Liquid soap or shampoo

Plastic teeth are gently wiped with a sponge soaked in detergent.

Vegetable oil

A few drops of vegetable oil placed in the slider will reduce friction when moving along the metal teeth.

Special graphite grease

Graphite grease is applied to the metal teeth so that the slider can even out casting defects.

Prewash

The zipper of the cotton tape should be washed before putting it on so that the material shrinks.

Repair Features

The zipper is the most vulnerable part of any piece. It is subject to constant mechanical stress, which leads to rapid wear. Replacing a zipper requires some experience. In some cases, for example in shoes, only a professional can do this using special equipment.

Jacket

You can repair your jacket yourself if you have a sewing machine. First you need to remove the old zipper. At the same time, the finishing and connecting seam is peeled off. A leather jacket has a glued ribbon: it must be torn off. In a fabric jacket, a new fastener is inserted in place of the broken one and glued to the lining. Close the zipper, check its operation. The seam is sewn on a typewriter. The upper part is sewn, sewn along the old seam.

In a leather jacket, a new zipper is first glued on both sides. After drying, the correct installation of the zipper is determined. The zipper is sewn with a seam, with the capture of 3 layers: trim, leather, reverse. The threads are strong, elastic (no fishing line).

Bag

If a leather bag is not attached, it is better to send it for repair. Cheap bags can be repaired by hand. Twisted zippers are installed on it, which are easy to replace.

Backpack

To change a failed lightning bolt, it is removed. The new fastener is straightened in an unbuttoned, sewn form. If the zipper has parted on one side, the fabric is matched, where the lower part of the braid is sewn. Put the tape in the slider and check the adhesion of the teeth.

When the zipper deviates again, the slider is pulled out and its edges are pressed with pliers. Strips with teeth are inserted into it.Fasten the lower part of the zipper with threads, sew on the traces of the old line.

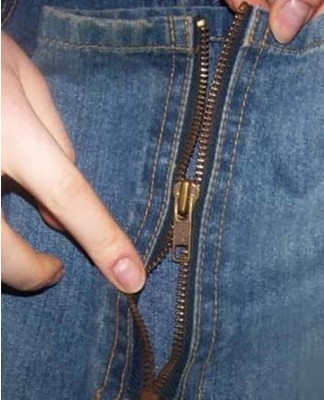

jeans

In jeans, a metal zipper is installed on the fly. Sewing a new fastener yourself can ruin the thing. The repair involves adjusting the sides of the slider to eliminate tooth misalignment.

Prophylaxis

A simple mechanism will last a long time, if you do not neglect simple rules:

- Do not jerk the dog sharply when opening and closing the lock. This can cause:

- breakage of the dog;

- tooth;

- misalignment of teeth;

- pinch the bottom lining;

- tear the fabric at the bottom of the zipper.

Move the slider smoothly and slowly.

- It is necessary to protect the metal fasteners from water and dirt. Clean in a timely manner, lubricate with protective cream.

- If the dog is "stuck", do not pull it forcefully.

- Tight boot tops, oversized clothes will cause the zipper to diverge.

Minor repairs should be done quickly, the zipper will last longer.