Composition and range of paint with liquid plastic, top 11 brands

Liquid plastic is a coating for metal and wood. It is used in daily life and in industry. The polymer used in the composition of the liquid hardens after being applied to the surface. Liquid plastics include interior paints, anti-corrosion enamels, protective body coatings and sealants. In the interior design of rooms, water-based emulsion paint with polymer is used.

Composition and characteristics of liquid plastic

The name "liquid plastic" includes various finishing materials: paint, enamel, automotive coatings, glue and polyurethane for molding. They differ in their composition and properties:

| Type of liquid plastic | Compound | Properties |

| Dye | Kohler, polyurethane, acrylic, alkyd | Forms a decorative film on the surface, dissolves with water. |

| Pigment, plastic, toluene | It fills microcracks and binds rust particles, prevents oxidation and corrosion of metal, protects the surface from the adverse effects of the environment. | |

| Protective coating for bodywork | Alkyd resins | A dense film protects the surface from the harmful effects of precipitation and reagents. |

| Adhesive putty | Cyanoacrylate | Forms a tight bond, binds natural and synthetic materials |

| Injection molded polyurethane | Base and hardener | The mass hardens in a mold, after hardening a transparent solid substance is obtained. |

Thanks to the plastic-effect body coating, the car looks clean and shiny, like after washing. A dye is added to the anti-corrosion compound to correct the color of the car. An analogue of liquid plastic is polycarbonate glass, from which greenhouses are built, and fiberglass for bottles.

Areas of application for plastic paint

Liquid plastic paint is suitable for wood, drywall, brick and concrete. Using plastic paint, walls and ceilings are prepared for wallpapering and finishing. The liquid polymer is used in the following areas:

- building;

- Finish the job;

- Automobile industry;

- shipbuilding.

Automotive markings are applied with polymer paint on city streets and highways. Water and gas pipes, fences, gates, metal safes are painted with liquid plastic. Polyurethane, acrylic and alkyd enamel protects surfaces from precipitation and ultraviolet rays. It is also used to cover wooden architectural decorations and balconies.

Advantages and disadvantages

The surface, covered with liquid plastic, becomes smooth and durable, acquires a brilliant shine.

The service life of liquid plastic surfaces is 10 years. The coating can be easily repaired and cleaned with detergents.

The paint quality of exterior walls is reduced by the action of water and wind. The enamel is diluted with toluene or a toxic solvent. Acetone and white spirit turn it into a liquid and weaker emulsion.

Terms of use

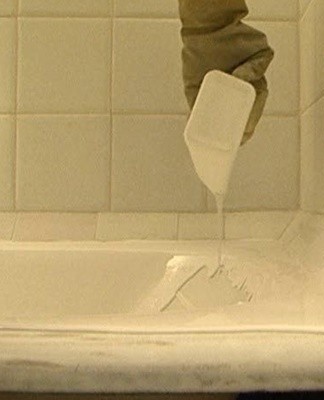

They work with liquid plastic at a temperature of + 5 ... + 35 degrees. After application, the paint hardens in one hour. For outdoor work, choose a dry, windless day. If the temperature in the room or outside is above thirty-five degrees, it is better to postpone staining. With the heat, the paint peels off. They do not work with liquid plastic in sudden temperature fluctuations and high humidity. Condensation will reduce the strength of the coating. The composition is applied by roller, brush or spray gun.

Surface preparation

The wall is cleaned of the old coating. Holes and cracks are putty. The surface is sanded with emery and coated with a primer.

Dyeing

The paint is applied in two or three layers. A one-hour interval is maintained between applications.

Completion

The liquid plastic is completely dry after 24 hours. Tools should be washed thoroughly after painting.

How to clean plastic paint

Fresh drops of water-based composition are washed off with water. Dry traces are cleaned with a knife. The enamel is removed with a solvent, with which the manufacturer recommends diluting it.

Review of the best brands

Two-component polyurethane compounds from foreign manufacturers are distinguished by high strength.

Cosmo SL-660.120

German plastic window glue of white color and thick consistency, does not stand out on light panels, does not yellow over time. Input in 60 seconds.

If you work in a ventilated place, the smell is barely noticeable. So that a plug does not form in the spout, a nail is inserted into it.

CLEAR CRYSTAL

A transparent two-component polyurethane mixture intended for casting decorative elements, optical lenses. Manufacturer - USA.

Transparent polyurethane is intended for professional use.

PolyCast

The Italian-made two-component plastic is used to make sculptures, models, jewelry and imitation bronze products. The composition is mixed and poured into molds. The plastic hardens at room temperature in 10-20 minutes. White color.

PolyCast plastic is used only for casting into molds. It is not suitable for household purposes.

NATICAST

Italian product of a series of polyurethanes for figured molding. 200 grams of the mix hardens in 5 minutes with hand mixing.

High strength structural elements, the milling plates are molded in Naticast plastic.

Polytek EasyFlo

The American product is used in the decorative arts and industries for the manufacture of plastic parts, models and structures.

The components are measured in a separate bowl, poured into a common container and mixed well.

Axson F160 from Axson

One of the best polyurethane plastics in the world for model casting is considered a French product. Both components are mixed by weight in a 1: 1 ratio.

Plastic is suitable for casting milling blanks, figurines and decorative magnets. Shake well before pouring.

JETICAST

Chinese polyurethane is also intended for the manufacture of models, decorative furniture, wood and metal imitations.

In cold weather, after transport, the components should be warmed to room temperature before mixing.

Domestic Manufacturers

Among Russian finishing materials, four brands of liquid plastic are most famous.

"SpecEmal"

Paint "Liquid Plastic" from the Yaroslavl company is suitable for interior and exterior finishing works, wooden and concrete-brick surfaces. It is also used to paint radiators.

The paint is resistant to extreme temperatures, withstands 5 freeze-thaw cycles.

"Sofradécor"

The textured paint is produced in Austria and supplied by the company "Technocenter" from Novosibirsk. It contains an acrylic copolymer.

The coating received a gold medal at the Interlakokraska exhibition.

"Silagerm 4010"

Household liquid plastic for molding.

Ideal for making imitation metal products.

Painting "PVC liquid TH"

The composition of TechnoNicol is used as a sealant to protect the joints of Ecoplast and Logigroof membranes from moisture.

Produced in 1 liter cans.

Additional tips and tricks

What you need to know about working with plastic paint:

- apply a composition with a pungent smell and toxic substances with gloves, a mask and a respirator;

- plastic does not require preparation, and metal, wood and concrete are pre-cleaned;

- collect a small amount of the composition on a brush or roller, so that when applied to the wall, the drops do not flow - they will not be hidden by subsequent layers;

- apply a new layer after the complete drying of the previous one;

- in order not to remove excess glue, stick mounting tape on the sides of the gaps.

Liquid plastic has its disadvantages and advantages, like all finishing materials. The main thing when working with the material is to follow the manufacturer's recommendations and safety precautions. Polymer paints, enamels and sealants are popular in modern construction due to their strength and decorative effect.