Technical characteristics and composition of PF-115 enamel, use and consumption

The legendary PF-115 brand enamel is used to paint all objects and surfaces. There are practically no restrictions on this type of paints and varnishes. The paint material can be applied to any base treated with a primer. After painting, a strong, thin and elastic film forms on the surface. The coating protects against moisture and does not change color for a long time.

General paint information

PF-115 was developed by Soviet chemists in the 60s of the last century. The basis of this paint and varnish product is alkyd varnish, or rather its variety. In the 70s of the last century, GOST 6465-76 was introduced to PF-115. In terms of performance, this type of paint materials is an order of magnitude superior to oil paints. Thanks to the resins contained in the composition, a solid film is created on the painted surface that protects the object from moisture.

Decoding of the abbreviation PF-115:

- PF - based on pentaphthalic resins (one of the varieties of alkyd varnish);

- 1 - for outdoor use (weatherproof);

- 15 - number in the catalog.

It is applied in 2 or 3 coats with a brush, roller or spray paint. Diluted with white spirit or solvent. Before painting, a primer with GF-021 or a primer of the same type is required. When used outdoors, the coating does not change color and properties for 4 years.

The main features of the PF-115:

- it has high decorative properties;

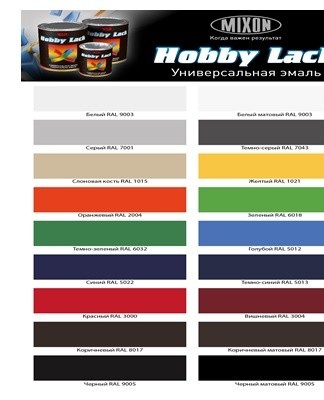

- available in different (more than 30) colors;

- creates a smooth, durable, glossy finish;

- the hardened layer of the film resists all atmospheric conditions;

- applies to any type of surface;

- protects against moisture;

- differs in light fastness;

- dries almost 24 hours after application.

Composition and specifications

PF-115 is a solventborne alkyd suspension composed of pigments, fillers and modifiers. Various types of this type of paint materials are produced. They differ from each other in the color of the pigment, the number of components, the percentage of constituent substances.

The main features of the PF-115:

- external service life - not less than 4 years;

- the period of conservation of decorative properties - one year (for outdoor use);

- internal service life - about 12 years;

- forms a glossy film;

- the coating can withstand temperature changes from -50 to +60 degrees Celsius;

- the conditional viscosity is 60-120 seconds according to the VZ-4 viscometer;

- the percentage of non-volatile substances - 49-70;

- a solvent is used for dilution to working viscosity;

- enamel consumption - 30-120 grams per square meter;

- drying time - 24 hours;

- bending elasticity of the film - no more than 1 mm;

- coating hardness - 0.15-0.25 conventional units;

- impact resistance of the film - 40 cm;

- density - 1.1-1.2 grams per 1 cm3;

- application temperature - above +5 ° C (up to +35 ° C), humidity - below 80 percent.

A liter of enamel weighs 890-910 grams. One kilogram of PF-115 contains 1.11 liters. Refers to a type of highly flammable paint. Has a pungent odor and poisonous composition. Enamels marked "BIO" can be used for interior work, painting walls inside living quarters. The composition of such paint materials includes biological components that prevent the development of mold.

Advantages and disadvantages

Apps

Purpose of PF-115 enamels:

- to paint all surfaces;

- for interior paint repairs;

- for facade works.

This type of paint material is used for painting wooden objects (tables, window frames, doors). It can be used for painting metals (gates, radiators, radiators, fences, metal elements). Using PF-115 they paint verandas, benches, garden structures. Enamel is used for painting concrete, plaster surfaces, stone, brick. Not only suitable for roofing work: in the event of strong temperature fluctuations, the film may crack or change color.

Coloring order

It is possible to paint the surface with alkyd enamel at an air temperature of + 5 ... + 35 degrees Celsius. It is recommended to prepare any surface before painting (clean, prime).

Quantity selection per color

Manufacturers produce PF-115 enamel in more than 30 shades. Before painting, you need to purchase a sufficient amount of painting materials for repair. It is best to calculate the area of the painted surface.

Usually manufacturers indicate the consumption of enamel in kilograms or liters for a certain number of square meters. The area to be painted is calculated by multiplying the length by the width. The result is taken in meters. As a rule, one liter of enamel is enough for 10 square meters. The consumption of paint materials depends on the method of application. The thinnest layer is obtained with a paint gun.

Most of the paint is consumed when painting with a brush. The consumption of paint materials also depends on the porosity of the substrate. Painting metal will require less enamel than painting concrete.

The chosen color of the product affects the consumption of paint materials. The fact is that each shade of PF-115 has its own composition. The highest consumption is for white paint, the lowest for black. One kilogram of red or snow-white enamel can paint over 10 square meters, brown, green and blue - 16, 14 and 12 square meters, black - 20 square meters.

Paint schemes

Each type of surface has its own paint characteristics. Before applying paint materials to the surface, the suspension must be well mixed, if necessary, add a solvent (no more than 5-10% by volume).

Metal

Before painting, surface preparation is necessary: removal of rust, degreasing with acetone or solvent, as well as sanding. The sanded base should be primed with an anti-corrosion metal primer.

Metal elements and structures are painted in 2 or 3 coats.The thickness of the film on the surface should be 18-23 microns. After applying the first coat, wait 24 hours for the coating to dry. The hardening process takes place at a temperature of +20 degrees Celsius. Heating the surface up to 100 degrees is allowed. In this case, the paint dries in 30 minutes. The second coat of enamel can only be applied after the first coat has completely dried.

Drink

Before painting, wooden surfaces should be cleaned of dirt, dust and peeling paint. Be sure to perform the grinding with sandpaper or an abrasive wheel of medium and fine grit. After removing the old coating, the wood is degreased and primed. After priming, wait at least 24 hours for the surface to dry. Only completely dry wood can be painted. Painting is carried out in 2 layers, maintaining the drying interval. The film thickness should be 20-23 microns.

Plaster, concrete or brick

Before applying the enamel, the surface must be cleaned of crumbling particles, leveled with plaster or putty. A primer is applied to a clean, smooth surface. After priming, wait at least 24 hours for the surface to dry. Only perfectly dry walls can be painted. Paint is applied to concrete or plaster in 2-3 layers, observing the drying interval. Film thickness - 20-23 microns.

popular brands

PF-115 enamel is considered a legendary type of paint materials. Many companies are engaged in the production of this suspension.

"Lakra"

It is a Russian manufacturer of decorative paints and varnishes. The company has been around for 20 years. Produces various types of paint materials, including enamels.

"Optimum"

"Leningrad paints" of the "Optimum" line are distinguished by the highest quality and a guaranteed long service life. Enamels of this company have their own distinctive properties.

"Fazenda"

Fazenda paints and varnishes are of good quality and long lasting. The manufacturer produces a wide range of products, including enamels.

Compatibility with other formulations

Different colors of PF-115 can be mixed together to achieve the required shade. It is forbidden to add other types of paints and varnishes to alkyd compositions. PF-115 is not applied over alkyd-acrylic, alkyd-urethane, perchlorovinyl, melamine, urea coatings. Enamel adapts well on polyvinylacetal, glyphtal, pentaphthalic, epoxy bases.

Storage conditions and periods

It is recommended to use the enamel as directed before the expiration date. Usually, the date of manufacture is indicated on the packaging or label. The shelf life of PF-115, as a rule, is 1-2 years.

Precautionary measures

Enamel painting is carried out using personal protective equipment. It is necessary to paint the surfaces in a respirator, goggles, rubber gloves. It is recommended that painting work be carried out in a well-ventilated area.It is forbidden to inhale the paint fumes and to use a suspension. If drops of paint come into contact with the skin, wipe the place of contamination with a cloth soaked in vegetable oil and rinse with warm soapy water. It is forbidden to work with painting materials near an open source of fire.