Technical characteristics of polyvinyl acetate water-based paint

When decorating interiors, one should not forget that the chosen material should be environmentally friendly, wear-resistant and durable. These characteristics correspond to water-based paints based on polyvinyl acetate, which, thanks to a wide palette of shades, make it possible to implement various design solutions. Such compositions can be used for finishing interior surfaces in residential premises and industrial facilities.

What is the difference between water-based PVA and dispersion

Polyvinyl acetate paints are characterized by the following characteristics:

- do not contain solvents;

- there is no unpleasant odor;

- after drying, they form an elastic coating;

- well absorbed in different materials.

These dyes are only used for interior work. Water-based PVA is produced white, and therefore materials of this type must be mixed with the appropriate pigments.

Polyvinyl acetate paints are not used in rooms with high humidity. Dispersion compositions in this vein seem preferable, as they contain special components that:

- increase moisture resistance;

- increase resistance to external influences;

- contribute to the formation of a vapor permeable layer;

- impart hydrophobic properties to the original composition.

Disperse dyes are versatile. That is, such compositions can be used in the decoration of various premises, including the kitchen and bathrooms.

Apps

As noted, PVA is used for interior decoration. You can paint with such compositions:

- glazed surfaces;

- TREE;

- concrete;

- brick;

- drywall;

- coated surfaces.

When purchasing polyvinyl acetate paints, keep in mind that these materials do not overlap with many primers. Also, this composition cannot be used for finishing metal products.

Composition and specifications

Polyvinyl acetate paints are composed of:

- An aqueous emulsion mixed with polyvinyl acetate. The main component of the dye, which gives the appearance of viscous sour cream. Due to the presence of PVA in the composition of water, it is necessary to store at temperatures above 0 degrees.

- Coloring pigments.

- Stabilizers that improve the characteristics of the material.

- Plasticizers. These components are responsible for the formation of a film on the treated surface.

Such surfactants dry out due to evaporation of water. Thanks to this process, the binders harden after application to the surface. Complete evaporation of water and, accordingly, drying of the paint takes 2-3 hours at room temperature.

Polyvinyl acetate compositions have the following characteristics:

- hiding power - class 1-2;

- density (depending on the type of components included in the composition) - 1.25-1.55 kg / dm3;

- viscosity (can be changed by adding water) - 40-45;

- drying temperature - + 5-30 degrees.

Polyvinyl acetate paints are available in two types: one-component and two-component compositions. The first can be used immediately for surface finishing.Such materials are recommended for processing small areas, as they dry quickly after opening.

Two-component paints are produced in the form of a plasticizer and a special paste, which are placed in separate bags. These components must be mixed before each use to obtain a working composition. Two-component paints are recommended for finishing large surfaces.

PVA, depending on the type of additional components included in the composition, is also subdivided into acrylic, silicate, mineral and silicone.

Acrylic

Acrylic compositions are characterized by a huge color palette, which, in combination with the above properties, gives these characteristics great popularity among consumers.

Silicate

Silicate paints are characterized by a long service life. If the application conditions are met, the applied layer will not require renewal for 15 to 20 years.

Mineral

Mineral paints, in comparison with those listed earlier, are distinguished by a narrow color palette, consisting of 8 shades.

Silicone

The advantages of silicone paints also include the fact that after drying the surface layer protects against the formation of mold.

Advantages and disadvantages of using

If necessary, you can change the degree of viscosity of polyvinyl acetate compounds by adding a certain amount of water. Such materials make it possible to obtain both matte and glossy surfaces.

When working with wood, it should also be borne in mind that the next layer should be applied after the previous one has completely dried.Also, after painting, the surface should be sanded with sandpaper.

Dye technology

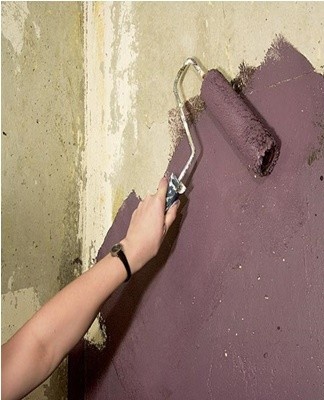

PVA surface painting is carried out within the framework of the following algorithm:

- Traces of dirt, dust and old paint are removed from the surface.

- Defects are repaired on the work surface.

- A primer is applied to the surface, then the selected dye is applied using a roller or brush in 2-3 layers.

In order for the dye to acquire improved properties, after drying, it is recommended to process each layer with sandpaper. This increases the adhesion, therefore each subsequent layer penetrates the structure of the treated surface better.

How to calculate the expense

The material consumption depends on the type of dye chosen. This parameter is indicated on the packaging. On average, it takes up to 150-200 milliliters per 1 m2, provided that the surface is painted in 1 layer.