Types and composition of neon paints and how to do it yourself at home

Neon paints, which accumulate ultraviolet light and glow in the dark, are more often used in the decoration of bars, discos and other similar establishments. But such a material can be used for other purposes, in particular, for decorating living rooms. Despite the fact that there are several types of neon paints, the basis of these products is a substance.

Characteristics and properties of neon paint

Luminescence, or the ability to glow in the dark, is a property that dyes acquire due to the addition of a phosphor (neon) to the original composition. This substance can accumulate solar energy during the day. After turning off the light, including artificial, the coating with a phosphor glows for 7-8 hours.

There is an important difference between fluorescent and fluorescent dyes. The former glow at night due to accumulated solar energy, the latter - ultraviolet radiation.

The composition of these dyes includes the following types of phosphorus:

- Organic. This phosphorus is based on naphtolic acid. This substance, accumulating solar energy, glows due to the radiation of neon lights.Due to this characteristic, organic phosphor coatings periodically emit momentary flashes.

- Inorganic. This phosphor consists of crystalline phosphor components that emit uniform and constant light.

In addition to phosphorus, in the manufacture of such materials, acrylic paints are used, which act as a binder.

This component has the following characteristics:

- versatility (suitable for finishing various materials);

- high plasticity;

- resistance to abrasion and other external influences;

- high speed drying (polymerization).

Distilled water or special mixtures are used as a solvent in neon dyes.

Scope

Glow in the dark paints can be used for:

- finishing of facades, entertainment facilities or structures in parks;

- the coloring of signs or warning signs;

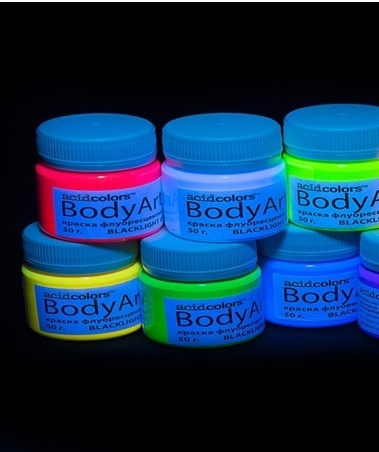

- body painting (body art);

- product labeling;

- road markings;

- registration of railroad fences.

Advantages and disadvantages of the material

Among the advantages of such finishing materials are:

- long service life (on the facades of buildings they are kept for 30 years);

- frost resistance;

- Versatility;

- chemical neutrality (does not cause allergic reactions and other side effects);

- does not collapse when exposed to temperature;

- tolerate direct contact with sunlight.

Luminous dyes have no drawbacks. It should be borne in mind that such compositions are used in highly specialized areas. For example, you can't paint rooms with glow-in-the-dark materials.

Varieties and recommendations for choice

Phosphorescent paints are divided into 3 types:

- Luminescent. The most popular type of phosphor-based neon paint. This composition is very resistant to external influences and does not harm humans. Therefore, luminescent paints are in great demand.

- Fluorescent. The basis of such a dye is acrylic varnish, which also does not harm the body. But fluorescent materials store ultraviolet light. That is, in order for such a coating to glow, a special lamp must be installed in the room. Fluorescent paints are available in a wide range of shades.

- Phosphorescent. Such a dye is rarely used, since the material is based on phosphorus, a substance that is dangerous for humans. Most often, phosphorescent compounds are used for finishing body parts.

Also, neon paints are divided into the following types:

- Colorless (translucent). These varnish-based materials are used to paint surfaces with an already applied pattern.

- Colored. In the manufacture of such neon paints, a pigment is added to the original mixture, which gives the composition a suitable shade.

In addition, for these materials, a division is applied according to the type of base component:

- Acrylic. These materials dry quickly and are used for painting various surfaces. In particular, acrylic neon paints can be used in body art.

- Polyurethane-mineral. They are mainly used for dyeing plastic.

- Heat resistant. An expensive type of paint that is used for finishing surfaces heated to 500 degrees.

- Raincoat. After drying, the paints create a moisture-resistant film, and therefore these compounds are more often used in the decoration of bathrooms and other similar premises.

The choice of neon paints is determined by the scope of application of the material.Acrylic compounds are considered optimal. Such materials can be used both for decorating the facades of buildings, and for decorating interiors.

In addition, there are luminescent paints on the market, which are produced in jars. Such aerosols are used to treat small areas. One spray can is enough to paint two square meters.

Luminous sprays, such as acrylic, are suitable for finishing a variety of materials, including drywall, wood, and concrete. Such compositions are often used to decorate structures located on the street.

The principle of using glow paint

It is necessary to paint surfaces with neon compounds, observing the following rules:

- before application, the surface is leveled, cleaned of dirt and dried;

- neon paint is well mixed (there should be no sediment);

- the composition is applied in at least 2 coats;

- the second layer can be applied 30 minutes after the first.

It is not recommended to use neon paints on black surfaces. This color also absorbs solar energy, which can negatively affect the quality of the basecoat shine. Therefore, if the surface cannot be repainted, a primer should be applied over the base finish before starting work.

It is recommended to paint in a shaded room. This will allow you to control the accuracy of the drawing.

Coating drying time and durability

The drying time of neon paint depends on the air temperature and the basic component with which phosphorus or another similar substance is mixed. On average, this process takes up to 3-4 days. In this case, the paint begins to gain strength 30 minutes after application.Therefore, work with such formulations should be done quickly.

The durability of the coating is also determined depending on the type of main component. The most durable are considered heat-resistant dyes that can withstand significant temperature changes. Acrylic and polyurethane resist mechanical stress well. And moisture-resistant coatings retain their original characteristics when in constant contact with water.

Paint Storage Guidelines

Phosphorescent formulations are recommended to be stored at temperatures up to +30 degrees, in a room protected from direct sunlight. However, these conditions also depend on the type of main component. Paints designed for metal processing can be stored at a temperature not lower than -30 degrees; glass: -10 degrees.

Make neon paint at home

To make neon paint with your own hands you will need:

- phosphorus;

- paint that will serve as the base (you can use transparent varnish);

- a solvent suitable for the type of dye chosen (distilled water is suitable for acrylic);

- metal, ceramic or porcelain container for mixing the components.

It is not recommended to make phosphoric paint at home, since this substance is dangerous for the body. But if the choice fell on this luminous component, then it is recommended to carry out work in gloves and a respirator.

To obtain a fluorescent dye, you will need:

- Pour varnish (another main component) into a prepared container and add a luminous pigment of the desired shade. The concentration of the latter is determined according to the effect to be obtained.Basically, the pigment is added in an amount of 25-30% of the volume of the base component (varnish or paint).

- Add a solvent with a volume of 1% of the resulting mixture to the container.

- To increase the light intensity of the composition, more coloring matter can be added to the mixture.

In addition to varnish or acrylic, you can use as a base:

- alkyd mixtures based on organic solvents;

- polyurethane mixtures, characterized by increased elasticity;

- an epoxy resin.

The type of base does not affect the volume of coloring pigment added: in each of the above cases, the proportion is 1/3.