Description and types of fluorescent paints, their colors and application technology

Fluorescent paints have been known since ancient times, when people used them for tattooing. The physical nature of the phenomenon became clear in the 18th century. The property of a pigment to emit light in the dark under the influence of UV rays has found wide application in the design of buildings, structures, premises and the creation of art objects. Reflective paints are used not only for creativity, but also for practical purposes: to protect against counterfeiting, to designate dangerous areas.

Content

- 1 Fluorescent paints: composition and principle of operation

- 2 Specific coating properties

- 3 where is used

- 4 The main difference with fluorescent

- 5 Varieties of formulations and selection recommendations

- 6 Shades and colors of fluorescent paint

- 7 Ranking of the best manufacturers

- 8 Application technology

- 9 How to make DIY fluorescent paint

- 10 Recommendations from the masters

Fluorescent paints: composition and principle of operation

Fluorescence is a physical process that is characterized by an "emission" of energy in the form of light waves under the influence of ultraviolet radiation. This property is possessed by certain chemical compounds with unstable bonds between the electrons of the atom.

For the first time, such a glow was observed in fluorspar (fluorspar). The addition of the Latin suffix - "escent" denoted the meaning of the term "fluorescent" - "weak action". Many substances have the ability to be fluorescent, the best known are quinine, xanthene dyes fluorescein, eosin and rhodamine. To obtain pigments, the dispersed polymer compounds are colored with fluorophores.

Fluorescent paint is an emulsion of pigments and a base for which you can use:

- the water;

- acrylic paint;

- urethane alkyds;

- an epoxy resin.

The reflective effect of fluorescent enamels is noticeable in the dark when exposed to artificial light.

Specific coating properties

The surface painted with fluorescent enamel begins to glow in the dark under artificial light. During the day, the transparent paint is barely noticeable, the light emission effect does not work.

where is used

Luminous dye is widely used in decoration and creating exclusive designs.

Areas of application for reflective paints:

- road marking;

- graffiti;

- design of outdoor advertising and signs for commercial enterprises, offices;

- design of interiors in entertainment establishments;

- car airbrush;

- painting the walls of living quarters;

- furniture restoration;

- arts and crafts;

- body painting, flowers;

- marking and adornment on clothing;

- creation of special effects.

Multi-colored shimmer finishes are compatible with all surface materials, which explains their growing popularity.

The main difference with fluorescent

Fluorescence is a type of luminescence. The difference between fluorones and phosphors is in the duration of the glow. The phosphors glow in the dark for 8-12 hours and do not require a power supply.The energy accumulated during daylight hours or under the influence of artificial ultraviolet sources is emitted at nightfall.

The fluorescent glow begins and ends simultaneously with exposure to ultraviolet rays.Under the influence of sunlight, the fluorescent pigment "burns out", the radiation fades.

Varieties of formulations and selection recommendations

Fluorescent glazes are available for a variety of surfaces, from textiles to concrete. To obtain high quality adhesion, the pigments are mixed with chemical compounds having properties compatible with the surfaces to be painted.

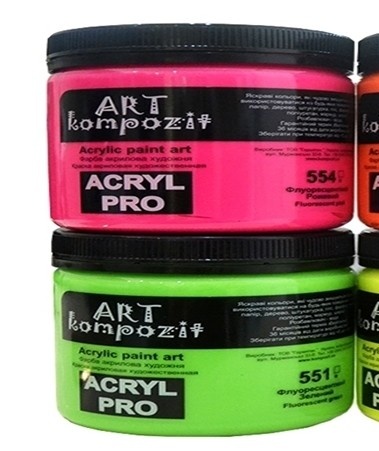

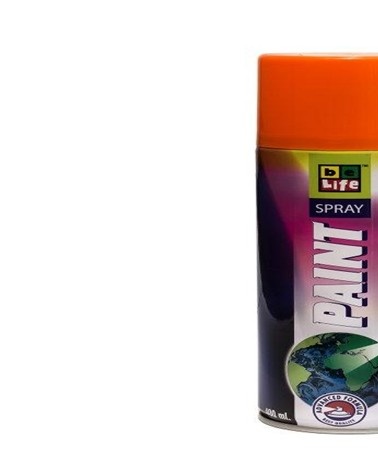

Acrylic

Acrylic paint based emulsion is non-toxic, creates a high quality coating.

Acrylic Luminous Enamels are designed to create a coating:

- on drywall;

- concrete;

- metal;

- TREE;

- Plastic.

In turn, acrylic compounds are divided into two categories: for interior and exterior use.

Advantages of acrylic compounds for interior work:

- high-quality adhesion to mineral surfaces, wood, plasterboard;

- non-toxicity;

- fire safety.

Disadvantages (compared to facade painting):

- low moisture resistance;

- destruction of the coating under the influence of detergents;

- sun exhaustion;

- poor adhesion to metal and plastic.

When decorating plastered walls, water is added to the paint.

Facade enamels can withstand extreme temperatures and precipitation.

They have high wear resistance, are resistant to the action of detergents and do not form mold under the enamel film. Acrylic luminous enamels are used in the design of buildings (when illuminated), housing, nightclubs and entertainment centers.

interior enamel

Interior paint is used to decorate the premises (residential and functional). Thanks to the water-based emulsion base, good adhesion to wood chips, plasterboard, mineral compounds (cement and lime plasters, concrete, brick) is ensured.

Advantages of the coloring composition:

- does not smell;

- non-toxic in contact with the skin;

- compatible with all living surfaces;

- applicable in the design of children's rooms.

Defaults:

- exposure to bright sunlight should be taken into account;

- do not use in very humid rooms.

Interior paint cannot be used for exterior use.

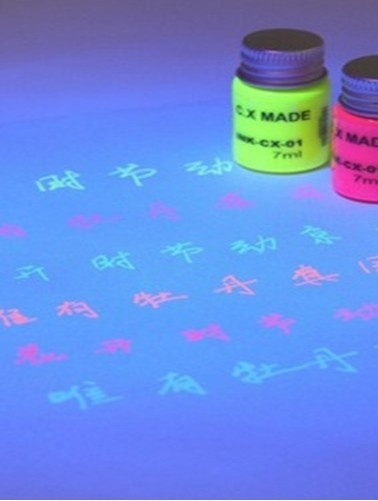

Ink

Printer cartridges are filled with fluorescent ink to create luminous images on paper used in interior decoration, titles and documents are marked.

Advantages of ink:

- effectiveness in detecting falsification of financial documents;

- protection of consumers against counterfeits;

- possibility of creativity.

Defaults:

- decrease in radiance after exposure to bright sunlight;

- high price.

Glowing ink is irreplaceable in the work of forensic specialists.

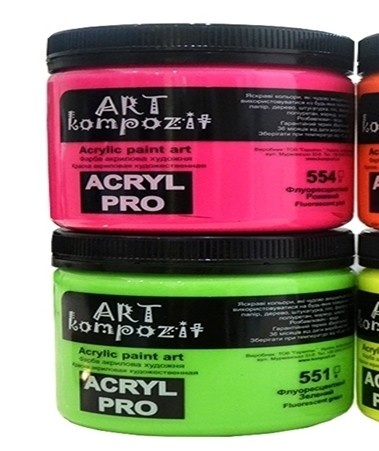

Aerosol

The basis of the emulsion of fluorescent spray paints are alkyd-urethane compounds.

This type of aerosol is intended for painting surfaces:

- made of metal;

- drink;

- glass;

- ceramic;

- concrete.

The easy-to-use canisters are used for airbrushing and tuning cars, creating graffiti, stained glass, art objects, marking objects and clothing.

Advantages of spray paint:

- thin-layer spraying, which creates a durable coating;

- the possibility of creative work without special painting skills;

- fast drying.

Disadvantages of composition:

- sun exhaustion;

- the presence of harmful fumes during coloring;

- danger when exposed to high temperature can.

Observance of the manufacturer's instructions makes it possible to obtain a high-quality coating.

Powder

Fluorescent powder is used for the manufacture of paints and varnishes.

Benefits :

- compatible with other pigments;

- used in paints, inks, aerosols;

- not toxic.

Default:

- insoluble, which affects the quality of the coating;

- loses its property with prolonged solar irradiation;

- does not apply as a separate component.

The quality of paint materials depends on the dispersion of the powder.

Shades and colors of fluorescent paint

The main chromatic color range of reflective enamels has six positions:

- YELLOW;

- red;

- blue;

- mauve;

- Orange;

- white.

These paints are visible in daylight due to the colorants added to the emulsion. In ultraviolet rays, they acquire a more intense acidic tint. By mixing, we obtain a varied palette of nuances: from raspberry to lemon.

Colorless fluorescent paints without coloring additives glow yellow-green in the dark.

Ranking of the best manufacturers

The most famous manufacturers of spray paints are Russian Technical Aerosols (Kudo brand) and the Taiwanese company R.J. London Chemicals Industries Co., Ltd. (Bosny brand).

The high quality of fluorescent paints is guaranteed by the companies:

- NoxTon (Ukraine);

- New Ton (Ukraine);

- AcmeLight (Ukraine);

- "Champion" (USA).

Russia, Poland, Ukraine are leaders in the production of fluorescent enamels.

Application technology

The technological conditions for the use of fluorescent enamels depend on the composition and purpose of the reflective compositions. But there are general requirements that must be followed in any case.For example, be sure to shake a can with an aerosol for 2-3 minutes before use.

During staining, periodically repeat the shaking procedure. Canned paint is thoroughly mixed before painting to achieve an even consistency. All surfaces except clear glass are primed with white compound to enhance reflective effect.

Preparatory stage

Before you start painting, the surface must be prepared. Each type of material has its own requirements.

Wooden surfaces are cleaned of the old layer of paint, polished, leveled, degreased with an alkaline degreaser. A primer is applied. Concrete and glass surfaces must be dusted, degreased, primed.

Application rules

The aerosol is sprayed at a distance of 25-30 centimeters from the surface, keeping the ball in an upright position. To achieve a good reflective effect, the composition is applied in 2-3 layers. The strength of such a coating will be higher than that of a single-layer film. The next layer is applied after the previous one has dried. Depending on the air temperature, the drying time is 25-30 minutes (at +20 degrees). It takes 24 hours for the film to harden completely.

Tools for applying acrylic-based emulsions:

- brush;

- roll;

- spray gun.

The technique of applying incandescent paint does not differ from standard techniques. The number of layers is at least 2. The second layer is applied 30-60 minutes after the first layer has hardened. The complete cycle lasts 24 hours.

Final finish

Fluorescent enamel loses its properties (burns out) under the influence of direct sunlight and when heated above 150 degrees.To prolong the service life, the painted surfaces are coated with a photo-protective and waterproof varnish.

Precautionary measures

The aerosol emulsion is in a pressurized canister. It is contraindicated to expose the bottle of paint to direct sunlight, place it near an open fire and heaters. Keep the enamel out of the reach of children.

Alkyd-urethane aerosol components can be toxic if painted in an unventilated area. Eyes and skin on hands should be protected from fluorescent enamel. The coloring composition based on acrylic is odorless, harmless to humans and animals.

How to make DIY fluorescent paint

To get a glowing paint at home, you need a fluorescent powder and a transparent component with adhesive properties, for example:

- varnish;

- glue;

- silicone;

- liquid glass.

The choice of base is determined by the characteristics of the surface to be painted. The pigment/base ratio is 1:10. The resulting composition is a suspension, since the powder pigment in the base does not dissolve. Stir the paint well before use. To smooth the grain of the coating, paint the surface in 2 coats.

Recommendations from the masters

To give the surface a brighter shine, a snow-white floor is needed. gThe adhesive compound must match the chemical composition of the surface to be painted and the enamel in order to achieve high quality adhesion. A single coat will be lighter than 2 or 3 coats and will be less durable.

If the aerosol is not used until the end, turn the can upside down and purge the spray head. Avoid staining in rainy, humid and cold weather (below +10 degrees). The temperature of the surface to be painted must correspond to the temperature of the air. Applying paint to hot surfaces can ignite the paint.