Types of paints for rubber and how to choose a composition, application technology

Paint for rubber products, especially for tires, will help improve their appearance and extend their service life. Tires can be completely repainted in the chosen color (black, gold) or simply write letters, draw a circle (white, yellow) on the side surface. Manufacturers produce special rubber paints that penetrate deep into the product and remain on the surface for a long time.

When to paint rubber

The tires are painted in different situations. Most often, paint is used to make old tires look presentable. Racers paint the tires before the competition, motorists and owners of rare and expensive cars paint the wheels before the exhibition. You can paint old and new rubber. However, before painting, the surface of the tire must be prepared (cleaned and sanded).

The rubber is painted to prolong its life. The elastic film formed after application on the surface protects the tires from abrasion, humidity, dirt, chemicals and strong temperature variations. The paint creates a hard but flexible finish. In addition, the composition penetrates the product, that is, makes it more durable.

Requirements for the coloring composition

For painting rubber products, special paints are used, which, after drying, give an elastic, strong and durable coating. These paints and varnishes (LKM) are made on the basis of latex, rubber or polyurethane. These components impart plasticity to the coloring composition. After all, rubber objects often stretch during operation, which means that the paint applied to the surface should not crack when stretched. The composition of paint and varnish materials for painting rubber includes various additives that give it abrasion resistance, excellent adhesion to the base and an attractive appearance to the painted product.

Criteria that rubber paints must meet:

- good adhesion to the rubber base;

- permeability inside the rubber;

- elasticity;

- strength;

- wear resistance;

- sustainability;

- decorativeness;

- additional protection against moisture, chemicals, weather.

Paint is mainly used to improve the appearance of a rubber product. Paints and varnishes for rubber can have a glossy, muted, matte or glossy standard color. Car tires are most often painted with black paint, and the sidewalls are painted with white or colored compounds.

The paint material should adapt well to the rubber surface. Rubber has good porosity. True, the tires are additionally treated with sandpaper before painting. Paints penetrate deep into the product and remain on the surface for a long time. In addition, the coating additionally protects the rubber from moisture, ultraviolet rays, oil and chemicals.

The additives included in the composition give the paint plasticity.The coating does not crack with regular stretching and compression, does not react to sudden temperature fluctuations. It is important to remember that wall paints containing latex are not suitable for painting rubber products. In such paints there is an insufficient amount of a component that gives plasticity to the coating.The ideal solution for dyeing rubber products are special rubber dyes. Usually on these paint materials they write: "Rubber paint", "Tire paint", "Liquid rubber".

Varieties of suitable paints

Manufacturers of paint and varnish materials produce various paints for coloring rubber products and restoring the color of car tires. In any case, the coloring composition will need to be applied to the rubber surface prepared for painting.

Types of paint materials for rubber products:

- Tire ink is a liquid for painting tires with a silicone compound. They are matte and shiny.

- Advantages - blackening gives the tire a rich black color, the coating is perfectly washable and does not wear out, protects against water and chemicals.

- Disadvantages - a short period of operation (several months), blackness strongly corrodes the metal (it is recommended to glue the surface not intended for painting in advance).

- Paint for tires KCH-136. The composition includes rubber. It is available in black, white, silver.

- Advantages - excellent adhesion to rubber, ideally smooth coating protects products from water, ultraviolet rays, adverse weather conditions, lasts up to 4 years.

- Disadvantages - toxicity, white spirit is used for dilution.

- "RESEL +" rubber paint to protect the surface from water. This paint contains latex and acrylic resin."RESEL +" is water-based, used for painting swimming pools, facades, driveways.

- Advantages - it is available in various colors, after application it creates an elastic and durable film that protects against moisture.

- Disadvantages - does not tolerate sub-zero temperatures, requires surface preparation for painting.

- Noris rubber stamp painting. Available in black and other colors.

- Advantages - gives rubber a rich color, dries quickly, does not crack, protects against moisture.

- Cons - it will fade over time.

- "Liquid rubber" (acrylic). Available in different colors. It comes in matte and gloss.

- Advantages - creates a strong elastic film on the surface, “merges” with rubber, protects against moisture.

- Disadvantages - high price, high consumption.

- White tire paint. It is used to paint the side surfaces of tires and apply letters.

- Advantages - excellent adhesion to rubber, dries quickly, creates an elastic film.

- Disadvantages - it gets dirty quickly.

- Liquid Rubber Spray RUNWAY. This is a paint in the form of a spray, a coloring composition based on synthetic rubber.

- Advantages - after spraying, it creates an elastic film, protects the surface from abrasion, moisture.

- Disadvantages - high price, high consumption.

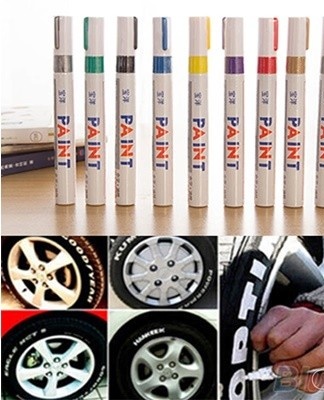

- Paint the tire markers. Available in different colors (white, silver, yellow).

- Advantages - ready to use, helps to write clearly visible letters on the side of the tires.

- Disadvantages - high price, quick consumption.

- I LOVE rubber (spray) paint. Completely ready-to-use dye for painting tires (in different colors).

- Advantages - creates a durable elastic coating on the surface, protects against moisture.

- Disadvantages - high price, high consumption.

- KUDO liquid rubber (spray).Aerosol products that create an elastic film on the surface. Available in different colors.

- Advantages - additionally protects the surface from moisture.

- Disadvantages - high price, high consumption.

Selection recommendations

To dye old tires, you usually buy a black dye. Such paint will help improve the condition of the tires, make them look presentable. Usually old tires are painted with compounds called "liquid rubber".

New wheels can be repainted in bright colors like yellow, orange, gold, silver. To paint the tires, they buy a special paint for rubber. You don't need to repaint the whole surface, just write letters on the side or draw a circle. For writing texts, white, bright green or yellow paint is used. The color of the letters is matched to the tone of the car. If the car is red, a red or white print is applied to the sides of the tires.

To paint tires, in addition to painting materials, you need the following tools and materials:

- brushes, rollers or spray gun;

- solvent (white spirit);

- fine grit sandpaper;

- detergent;

- sponges, rags;

- adhesive tape, electrical tape, plastic wrap.

Tires are usually painted in 2-3 coats. Double or triple application of the coloring composition improves the decorative qualities, and also protects the surface from moisture. When buying paint, you need to take into account its consumption. Usually the label indicates the amount of paint consumed per square meter. It is recommended to immediately purchase the entire volume of the coloring composition for repainting the tires.

Tire painting technology

The appearance of tires depends not only on the right paint, but also on the paint technology. Rubber can be repainted at home, that is, in an ordinary garage. You will not need special accessories and tools for painting. All paints are applied to the surface using a spray gun, brush or roller.

Additionally, most dyes are thixotropic. This means that the paint under mechanical action (in the process of mixing, applying) becomes liquid, and at rest, on the contrary, viscous. The painted base evens out by itself, after a few minutes after painting, the traces of the brush completely disappear from the surface of the tire.

Tire painting involves three main steps:

- preparation of paint and surfaces to be painted;

- pump tires;

- dyeing process.

Preparing the surface for painting begins with cleaning. It is recommended to clean the tires from dirt, dust, various stains, old paint. The tires are washed in soapy water and then dried. Dry tires are wiped with a solvent (white spirit) to remove gasoline and oil. You can use rubbing alcohol to clean greasy stains. It is advisable to sand the dry surface of the tire with fine-grain emery paper, then degrease it again. A slight roughening will improve the adhesion of paint materials to rubber.

It is recommended to prepare the paint before painting. Too thick a coloring composition can be diluted with thinner or water (depending on the type of paint). Pigment is added if necessary. It is recommended to mix well before applying to the surface.Latex and rubber paint materials may be slightly warmed before use. Warming will make the paint thinner. If a coloring composition in the form of a spray is used, it is recommended to shake or shake the can well.

After preparing the surface for painting, use ink or tire paint. Dyeing the rubber with dyes helps give the product a presentable look. True, the performance characteristics of blackeners are worse than those of paints.

Only the outer surface of the tires is painted. The inner face is not visible. You can paint only the sidewalls of the tires and leave the working surface in contact with the road unpainted. Some car enthusiasts put different markings on their tires. For writing letters, white rubber paint is most often used.

Before using the coloring composition, it is recommended to protect the areas that will not be stained. These places are sealed with tape, electrical tape or covered with plastic wrap. The tires are painted dismounted. True, it is recommended not to disassemble the wheel before painting, but to pump it to a working condition, so that the coating applied later when painting does not crack during operation and stretching . In this case, stick the disc with adhesive tape.

Paint materials are applied to the tire surface using a brush, roller or regular paint sprayer. You can spray the coloring composition from an aerosol can, if an aerosol is used. The paint is applied to the tire in 2-3 layers. The coating should not be too thick, otherwise it will crack during use.After applying the first thin coat, wait several hours for it to dry completely, then paint the surface again.

Fully painted tires dry for approximately 24 hours. True, they can be used only after 7 days, when the polymerization process is completed.

Tire painting can be done in the garage. The main thing is that the air temperature is above 10 degrees Celsius. When working with paint materials, you need to remember about the protection of the respiratory system and eyes (use a respirator and goggles). During drying, it is necessary to ensure that moisture and dust do not get on the painted rubber. It is recommended to store leftover paint materials away from an open source of fire.