The device and dimensions of spray booths for cars, their types and principle of operation

Body painting is carried out under special conditions. Otherwise, the applied material will not lay flat on the metal and therefore the operation must be repeated. To avoid such consequences, the procedure is carried out in a special spray booth, which maintains the required temperature and level of humidity, and also filters impurities from the air.

What is a spray booth for cars?

When painting a car body, the following conditions must be observed:

- warm the air to a certain temperature;

- remove large and small dust particles from the air;

- bring the pressure to a certain level.

It is also recommended to install bright lighting that will reveal all the paint defects on the various parts of the body.

These conditions are met by a special paint booth, which:

- automates the painting process;

- independently controls the level of pressure and air temperature, if necessary, by changing these parameters;

- removes volatile elements from the air;

- made of explosion-proof materials.

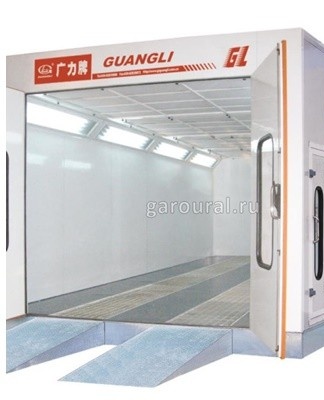

The spray booth is a special box with a sliding door, the dimensions of which are 1.5-2 times larger than the dimensions of the car. Outside of this structure, most of the built-in automation controls are located. If this box allows the car to be dried, then the walls and floor are additionally insulated by means of mineral wool, expanded polystyrene or fiberglass from mineral components based on acrylic binder.

The principle of the device and the operation of the paint booth

A paint booth for painting a car should include the following:

- Air compressor with a pressure of 8-12 atmospheres. This unit must be equipped with an oil and water separator and a tank.

- Fans. For a paint booth, an inflator and a supply will be needed.

- 4 spotlights of 1.5 kilowatts containing halogen lamps or a heat gun. These components are necessary for drying the body.

- Fabric hydraulic filters.

- LED lights.

- Long fluorescent lamps.

- Reinforced polypropylene film.

In addition, the spray booth contains a heating element. In addition, the boxes must be equipped with a process automation system that maintains the required parameters (air temperature, humidity and others) at a given level.

The presence of two filters is considered mandatory for painting the chambers:

- Rough cleaning. This filter is located behind the fan. This unit is designed to remove paint particles and dust, solid contaminants from the air. This filter protects the second fan.

- Fine cleaning. It is mainly composed of leaf or honeycomb filters, which remove the smallest contaminants from the air.

When choosing such boxes, the following should be taken into account: the design of the chambers should provide reliable protection against explosive gases,exclude the reverse movement of heated air through the pipes and automatically turn off the heating with the fan. In addition, you should pay attention to the power of the devices used. In particular, if a weak fan is used, areas of turbulence may form inside the box, due to which the paint will lay unevenly.

In order to save energy, the paint booths are equipped with an air recirculation system, which is started after the car has been painted. To do this, the supply and exhaust vents are interconnected by a valve.

Painting a car in such a chamber is carried out in several stages:

- Air is taken from the outside, after which the incoming masses are cleaned of contamination.

- Air injection and warming up to 25-30 degrees.

- Car painting.

- Machine drying, during which the air in the box warms up to 30-60 degrees.

The painting procedure depends on the type of car and a number of other characteristics. Passenger cars are treated with spray guns. But for painting large vehicles, a special water curtain is used.

That is, in this case, enamel is supplied in a continuous stream from nozzles located in the ceiling and walls.

Main varieties

The classification of paint booths is carried out according to several criteria. According to the design of the ventilation system, these boxes are divided into the following types:

- with exhaust valves around the perimeter (considered the best option);

- with exhaust valves located inside the floor gaps;

- with exhaust engines hidden on the ground in special trenches.

On the same basis, the following housing types are distinguished:

- Pressure chambers. These models are more popular than the others. In such boxes, more efficient blowing fans are used, which, by increasing the internal pressure, prevent dust and other contaminants from entering the chamber. Thanks to this design, the part does not require additional sealing.

- With a passing air current. In this case, 2 fans of the same performance are used.

- With wind. In such a room, the exhaust fan is more efficient than the blower fan.

According to design features and performance, spray booths are divided into the following types:

- Industrial models. In such boxes, devices are provided for painting large vehicles, conveyor belts (rails), hydraulic baskets and other devices.

- Business models. This type of enclosure is intended for painting cars, due to the size of the chamber.

- Household models. This type of cameras is equipped only with the necessary devices.

In addition to these gradations, the classification of paint booths is carried out taking into account the design features. In large-scale production, passing (travel) models are used, which allow continuous processing of car bodies as part of the assembly process. Commercial boxes have a dead end design with a door for vehicle entry and exit.

What you need to pay attention to when choosing

When choosing a box, you should pay attention to the following points:

- Fire safety level.This parameter depends not only on the above circumstances (type of finishing materials, nature of ventilation, etc.). Also, in order to avoid a fire, the box must be equipped with an extinguishing system.

- Design. In a high-quality box, in addition to the presence of ventilation and heating, "dead" zones should be excluded.

- The nature of fans. To paint cars, air must circulate at a speed of 0.25-0.35 m/s.

- Heat exchanger power.Built-in equipment should maintain the temperature at +22 degrees.

- The nature of the lighting. The brightness of the devices used must not be less than 1200 lux. The lamps in the boxes are located above and below.

- Base. It is better to use chambers with a concrete base.

- The presence of an emergency exit.

In addition, attention must be paid to the operation of the drying chamber. This process should take no more than 20 minutes. It is also important to consider the nature of the operation of the control panel. This process should be operator friendly. And paint control is carried out using built-in automation.

Review of the best models

The selection criteria above correspond to three brands of cameras:

- OSKAM;

- OSKAS;

- Nordblerg.

Products of these brands differ among themselves in the power of the installed fans, dimensions, characteristics of the heat exchanger and other parameters. The companies "OSKAM" and "OSKAS" produce boxes with similar properties, and therefore the price of these products is the same.

Nordberg brand boxes are considered more expensive.This is because this company uses Italian, Taiwanese and Chinese components in the manufacture of its products. Nordberg boxes are certified in Europe and the USA. In particular, Phillips lighting devices are used inside the cameras of this brand.