Varieties of zinc paints and top-6 formulations, application technology

Zinc paint (rich in zinc) with high zinc content (from 80% and above) based on resins and solvents is used to paint and protect metal objects from corrosion. Paints and varnishes containing zinc create a beautiful silver coating that does not change its appearance and properties during operation for a long time.

General information on paints containing zinc

Paints and varnishes containing a high percentage of zinc (80-95% and more) provide metal objects with long-term protection against rust. Paints containing zinc, or rather loaded with zinc, are used to paint or prime metal. They are applied to the iron base using a brush, roller and spray gun. Painting metal with paints containing zinc is called cold galvanizing. This method is an alternative to hot-dip galvanizing.

After applying zinc-containing paint materials to the base, a corrosion-resistant film is formed. The zinc in the paint prevents moisture from destroying the iron. Zinc powder and resins create an anti-corrosion barrier on the painted surface.

However, after the application of paint containing zinc, there are still micropores in the fresh coating which allow moisture to pass through to the iron (contributing to rust formation). However, as soon as the oxidation reaction occurs, zinc oxides and zinc bicarbonates are formed. A film of zinc forms, filling the smallest pores and "healing" the defects on the surface of the metal. In another electrochemical reaction, zinc carbonate is formed. It is also a water resistant film.

The zinc coating has the ability to self-repair if its integrity is violated during operation. Penetration of moisture causes an oxidative and electrochemical reaction. As a result, a new film and a new anti-corrosion barrier are formed.

All paints containing zinc (rich in zinc) cannot be used for cold galvanizing. It is advisable to purchase not zinc paint materials, but zinc (fine powder 3-5 microns (88%) or fine powder 12-15 microns (94%)) with the addition of resins and solvents. Such formulations are often referred to as zinc primers. Another name for them is liquid zinc. Simple zinc-based paints with a low percentage of zinc powder do not provide long-term corrosion protection.

Apps

The cold galvanizing method is used for painting:

- metal objects used outdoors;

- metal bridges, hydraulic structures, electricity pylons, road barriers;

- radiators, batteries;

- pipes, rolled metal products, containers, tanks;

- vehicle bodies, ship hulls;

- construction of metal structures;

- gates, fences, doors, metal elements;

- to restore a previously galvanized surface;

- water, gas and heating pipes.

Varieties

Paint materials containing zinc, in addition to zinc, contain resins: organic (epoxy, alkyd, chlorinated rubber, urethane) or inorganic (silicate). Cold galvanizing paints and varnishes can be one-component or two-component. The compositions, consisting of two semi-finished products, are combined with each other and mixed before use.

Epoxy

Epoxy-based paints and varnishes are considered the most durable. Zinc-filled compounds containing at least 85 percent zinc powder are used for corrosion protection of objects in the oil, gas, power, and waterfowl industries.

alkyd

The most common paint materials containing zinc. Available as spray or liquid paint in cans. It is used to protect metal elements and structures from rust.

Urethane

Urethane or polyurethane paint materials filled with zinc are used to protect metal objects from rust. May contain up to 96 percent zinc. Suitable for cold galvanizing.

Chlorinated rubber

This is a zinc-based chlorinated rubber primer. Creates a coating resistant to moisture, acids, petroleum products.

Silicate

They are generally two-component heat-resistant compounds. They are used to protect metal objects heated during operation from rust.

Popular formulas

Manufacturers of paint and varnish materials produce a huge amount of products containing zinc powder. Zinc coatings have good anti-corrosion properties and long life.

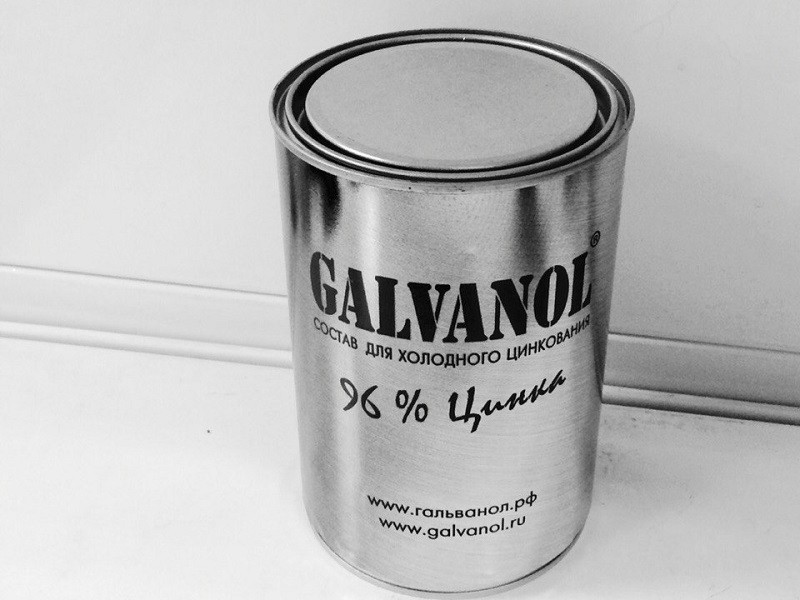

galvanol

It is a composition for cold galvanizing metal objects, elements and structures, containing 96 percent zinc. It is used as an independent anti-corrosion coating or as a primer. Forms of packaging: spray cans, liquid paint and varnish in spray cans.

Tsinotan

It is a polyurethane compound containing zinc (80% zinc), which is used as a primer for metal or as an independent decorative coating. Sold in cans.

Tsinotherm

It is a heat-resistant organosilicon paint material with a high zinc content. Original packaging - cans.It is used to protect against corrosion of metal elements and structures that operate at high temperatures.

Zinkor

It is a 96 percent zinc primer. It is used to paint and protect metal objects from corrosion. Recommended for repairing galvanized surfaces.

Zincconol

This is a zinc-rich (96% zinc) polyurethane paint material to protect metal objects from corrosion. Can be used as a primer and as a stand-alone coating. Protects the metal base from the effects of water, steam, acids, alkalis, petroleum products.

CEEC

It is a two-component zinc-rich composition (85% zinc) that protects metal objects from corrosion. It is used as a primer or as an independent coating.

How to choose the right composition

When buying paint materials containing zinc or filled with zinc, first of all pay attention to the percentage of zinc in the composition (not less than 85%). The color of all paints is the same - silver-gray with a matte sheen.

The recommended consumption is approximately 300 grams per square meter. Paints containing zinc must form an anti-corrosion coating with a long service life (at least 25 years).

Cold galvanizing technology

Coloring steps (alone):

- Surface preparation for painting (remove old coatings, remove rust, sand to roughen the surface, degrease with a solvent).

- Preparation of the composition for coloring (shake the can, dilute with a solvent (for one-component paints in cans) or mix two semi-finished products (for two-component paints with a hardener)).

- The process of applying paint materials to a perfectly clean and dry surface (using a natural bristle brush, short-haired roller, spray gun, or dipping).

- The paint is applied to the metal in 2-3 layers, the primer is applied 1-2 times (with an interval of 60-90 minutes for each layer to dry).

- The temperature of the metal surface to be painted must be 3% above the dew point (dry, no icing).

- After application of the topcoat, the zinc coating must dry for at least 24 hours.