Varieties and colors of paints-chrome, the 4 best manufacturers and how to apply them

Chrome plating is a technology for coating metal surfaces with small aluminum particles. As a result, the details become shiny and smooth. Chrome was used to decorate car bodies in the middle of the 20th century. Later, the cold sheen of metal migrated to modern interior design styles. A simplified version of industrial chrome steel available to consumers of chrome effect paints.

Peculiarities of chrome paints

The main difference between chrome paint is a mirror surface. Other characteristics of the coating:

- available in three forms - aerosol, can and powder;

- applied by brush or spray;

- requires leveling, degreasing and cleaning the surface from dust;

- A black nitro enamel or varnish is used under the base.

Chrome paint creates a mirror-like surface on plastic, wood and also protects metal from corrosion.Compositions are used for painting cars, plumbing fixtures, interior details, Christmas tree decorations, souvenirs.

Composition and characteristics of chromium compounds

Chrome paints are divided into three types, which differ in strength and purpose. But each of them contains aluminum powder.

Monocomponent

Spray paints are one-component formulations. The aluminum particles they contain are combined with an alkyd or nitrocellulose varnish. The formulations are ready to use, long lasting, dry quickly and are easily sprayed without any tools at hand.

Aerosols are used to paint small parts, plastic, wood and glass products: car rims, bumpers, moldings, door handles and fittings. Chrome spray paint is suitable for all surfaces, provided it is properly prepared.

Bi-component

Two-component paint with chrome effect in pots. Comes with acrylic or epoxy hardener. Both components are mixed and applied to the prepared surface.

To paint with two-component chrome paint, use brushes or a spray gun. It is also suitable for surfaces made of various materials. The difference between chrome paint in a can and in an aerosol is that it is practical to use for painting large surfaces and individual parts: furniture legs, lamps, bodywork, bicycle frame, motorcycle exhaust pipes.

Powder

Powder chrome paint is characterized by its heat resistance, anti-corrosion properties and durability. But the staining takes place according to a more complex scheme: a nitrocellulose varnish is applied to the cleaned surface, sprinkled with powder on top, and then baked in an oven at a temperature of 180 degrees.Under the influence of heat, aluminum melts and hardens with a durable shiny layer.

Powder coat paint is used to paint alloy rims and grilles under chrome.

Advantages and disadvantages

It should be remembered that mirror paint only creates a chrome effect. Chrome spray paint can be used to redecorate scratches on real electroplated chrome. But it is not advisable to repair surfaces painted with two-component paint with. They differ in composition, so the painted mark will stand out.

Coating options

Various dyes are added to the chrome paint, which creates a unique special effect.

Classic

The composition with a natural white-silver color of aluminum is considered a classic. The surface looks like a mirror, as if covered with a white sheet.The classic white imitation of chrome is found in the design of furniture pieces for living rooms, bedrooms and kitchens, as well as on the gutters for curtains and jewelry.

black chrome

A translucent black dye is added to the aluminum powder. The dark paintwork looks impressive on the wheels and grilles of the cars. A more discreet option is matte chrome. It is devoid of remarkable shine. Surrounding objects are only reflected in a muted color. Matte finish is more often used indoors.

Colored chrome plating

Among the colored dyes, golden compositions are the most popular. They contain a yellow metallic powder. With the help of shades of yellow, they create an imitation of gold or brass. Like classic silver, gold plating is found on lamp shades and brackets, floor lamps, on the beams of curtain rods, doorknobs, and interior decor.

Chameleon

The most interesting, but least practical option for coloring is using a composition that changes color with increasing temperature. Thermochromic chameleon paint is of two types:

- reversible - colored or white, changes color when heated and returns to the original when cooled;

- irreversible - changes the hue once and is not restored.

Chameleon painting is not very common in everyday life. With a transparent composition, drawings are applied to glasses and cups, which appear from hot drinks and disappear when cooling. In industry, a color-changing compound is used to paint indicators that warn of a critical temperature increase.

How to choose the right chrome paint

When choosing a mirror effect coating, consider:

- painted surface area;

- the degree of its susceptibility to mechanical damage, adverse weather conditions, high temperatures;

- who will paint - an amateur or a professional;

- the purpose of coloring is to create an artistic chord or give a slight sheen.

Only two-component paint is suitable for painting a car. After several training sessions, an amateur motorist will be able to cope with it. But if you are unsure of your abilities, it is better to contact a car service. When choosing a paint that imitates chrome, the properties of the components and the nuances of the work are also taken into account.

The acrylic hardener is resistant to high temperatures and chemical solvents. Two-component composition can be applied to individual areas and create color transitions.

A one-color coating is made with a powder dye. Powder coating is considered more durable than others, but the result depends on the skill of car service employees and the quality of the composition.

Perform coloring

In order for chrome paint to last a long time, you need to properly prepare the surface. General rules for working with chrome paint:

- requires almost sterile cleanliness in the room, complete absence of dust;

- smooth surfaces of any material and primer should be sanded to improve adhesion;

- Apply coats of chrome stain at intervals after drying.

To make the coating more durable, it is fixed with varnish. You can varnish any paint - from an aerosol, canister or powder.

Plastic

Method of painting plastic parts:

- clean the surface with emery;

- first;

- apply chrome paint.

It is recommended to warm the plastic a little after the primer dries. Without a primer, the mirror coating will peel off quickly. When the painted surface is dry, it must also be polished.

Metal

How to paint a metal part:

- clean rust and dust;

- degrease with alcohol;

- cover with an anti-corrosion primer or a black nitro enamel;

- polish primer;

- apply paint in a thin layer.

To achieve the effect of chrome plating with an aerosol, a minimum of three coats is required.

Popular manufacturers

The durability of chrome plating depends on compliance with the paint technology, as well as the quality of the paint. In the paint and varnish market, four manufacturers produce high-quality chrome paints for car tuning and home use.

RUSH Power

The color and coverage of RUSH Power chrome paint, in general, leaves a pleasing impression on street performers. The main thing is not to forget to shake the can, otherwise the spray will release a thick foam.

CHROMIUM

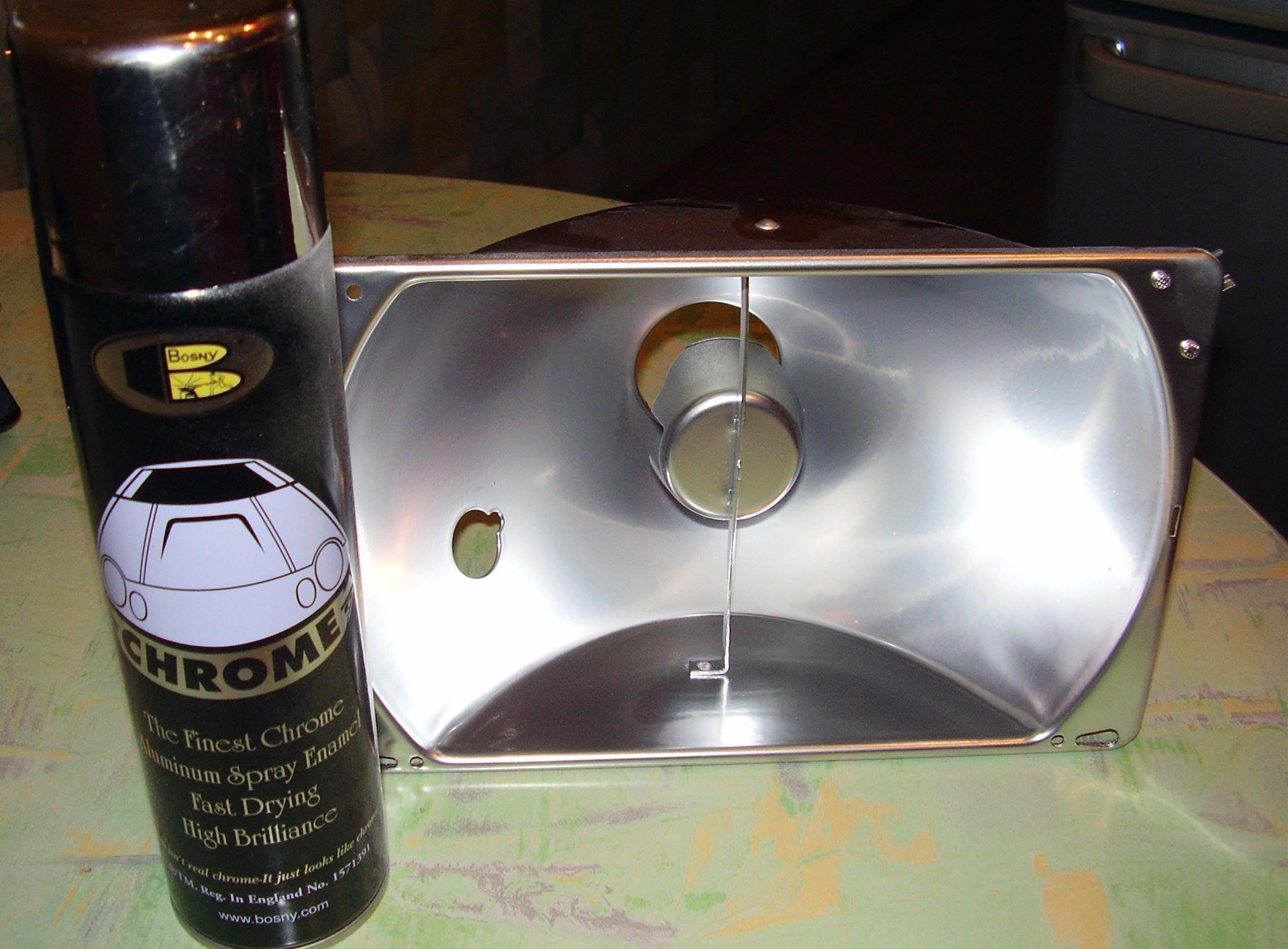

Bosny chrome paint is suitable for crafts, painting small parts. It is not recommended to be used for painting the car body. A more durable coating is obtained on a porous surface.

Chrome effect

Special paint for tuning cars from Alsa consists of a base, paint composition and varnish.

Self-coloring requires training. First, lacquer is applied to the surface, after careful polishing, chrome is applied.

ASTROHIM

Spray enamel is intended for painting car rims.

The surface is painted in a silver-gray color, as after silver painting. Polishing and varnishing does not help to improve the appearance. ASTROHIM enamel is suitable for painting small rooms without a high aesthetic appearance.

Solve common problems

Difficulties that most often arise when painting with chrome paint:

| Issue | Cause | Solution |

| Lagging behind quickly | Surface too smooth | Emery primer, base paint and chrome paint |

| Dries slowly | Low ambient temperature | Dry with a hair dryer |

| Falls to pieces | Dust hit the surface | Keep the surface clean at all stages of finishing |

| Fades quickly | Poor quality paint, violation of application technology | Before painting, it is imperative to degrease and prime the surface, especially the metal. |

| Does not hide a defect, a trace of rust | Low covering power of the composition | Apply in three coats |

| don't shine | Bad spray paint | Varnish |

| Inflated after the opening | Incompatibility of paint and varnish compositions | To cover nitro paint with varnish based on nitrocellulose, epoxy - with varnish based on epoxy resins, acrylic - with acrylic composition. |

| Porous surface after drying | Application in a single thick coat, the previous coat is poorly dried | Wait until the surface is completely dry and apply the paint in thin layers |

It is possible to achieve a mirror-like shine on the bumper and discs when using aerosols if the surface is well cleaned with fine-grit emery. In this case, the paint will require 1-2 thin layers for toning.

A durable glossy finish is formed by a varnish applied in two coats. Each layer of varnish must be polished. To avoid the problem of compatibility of coatings, the paint and the varnish must be chosen from the same manufacturer.