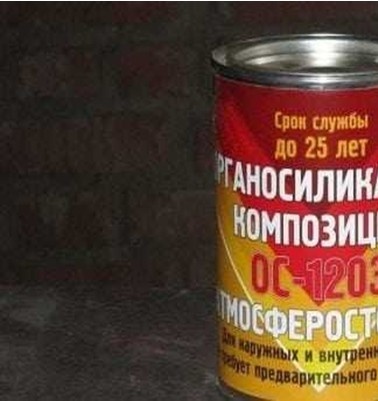

OS-12-03 specifications and consumption of organosilicate composition

Organosilicate composition is a material used to cover technological or electrical equipment, as well as various structures of industrial buildings. Supporting structures made of metal or concrete are covered with paint. OS-12-03 - organosilicate composition of innovative origin. "OS" is the designation of the nature of the material, and "12-03" is the article by which the painting can be found in the catalog.

Organosilicate composition OS-12-03 - technical characteristics

Organosilicate paint is made from organosilicon polymers. It belongs to the category of weather-resistant materials, characterized by a long service life without loss of quality. The paint is produced in accordance with technical standards.

Composition and properties

The basis of the coating is a finely dispersed suspension of layered hydrosilicates. Various pigments are added to it, giving color to the coating, as well as auxiliary additives in the form of solvents on a different basis.

OS-12-03 according to its technical characteristics belongs to the category of one-component enamels, which combine well with other enamels and primers.

The advantage of painting is to obtain an environmentally friendly coating. This occurs after the solvents have completely evaporated from the painted surface as the coats dry. After 48 hours, no chemicals remain on the surface.

Basic properties of OS-12-03:

- formation of a coating in the form of a uniform matte finish without impurities;

- the formation of a uniform saturated color;

- polymerization of the film at a temperature of +20 degrees;

- the dry residue is 55 percent;

- drying time - 3 hours;

- the enamel has a high impact resistance;

- the adhesion of the layers is equal to 2 points on a special scale;

- taking into account compliance with all the necessary rules, the water resistance of the coating is achieved 24 hours after applying the topcoat;

- the bending elasticity test of the film is 3 millimeters;

- the covering power is 60 or 110 grams per square meter (the exact indicators depend on the chosen shade);

- the paint can withstand temperatures from -60 to +300 degrees.

In vivo drying assumes an air temperature of +20 degrees.

Scope

Enamel 12-03 has high anti-corrosion properties and good weather resistance. The paint does not fade under the sun's rays, it has the electrical insulation properties of the created coating. The qualities listed determine the area of application.

Organosilicate composition 12-03 is intended for:

- create coatings in industrial installations, where the main objective is to obtain a protective and decorative effect;

- for painting metal, reinforced concrete structures;

- to decorate various buildings.

The manufacturer claims that the paint protects the coatings of metal bridging structures of bridges, outdoor chimneys, tanks and autoclaves from natural corrosion due to atmospheric agents. In addition, the paint protects against corrosion in gaseous environments with medium attack types.

Application of the composition helps protect against damage to surfaces that are under high temperature operating conditions. This group of elements includes technological equipment, automatic ovens and gas ovens.

Advantages and disadvantages of enamel

Organosilicate compositions are a special group of materials used for specific purposes. Paint 12-03 has advantages and disadvantages.

| benefits | Disadvantages |

| Formation of a uniform matte film | Features when working with paints |

| High adhesion rate | It is imperative to use increased measures to protect hands, clothes, face when coloring |

| Availability of a catalog with various shades, the possibility of ordering the desired color | Application specificity

|

| Wide operating temperature range | |

| Selection of application methods | |

| High resistance to humidity, temperature, biological or chemical corrosion |

The composition shows high adaptive properties. This means that after complete drying, the coating is resistant to sunlight. The color does not change for a long time. After 6-8 years of operation, a deviation of several units from the main shade is possible.

At what temperatures and humidity is it recommended to use

OS-12-03 is applied at temperatures from -30 to + -40 degrees. At the same time, the air humidity should be 80%.Painting work is completely stopped if it starts to rain, hail or snow. Also, painting is not carried out at wind speeds above 10 meters per second. Separate requirements are imposed on the temperature of the surface to be painted.

The reading should be 3 degrees above the dew point.

Requirements for OS-12-03

In the production of the composition, samples are used that are regulated by the technical passport. OS-12-03 must meet the basic requirements:

- creation of a uniform coating with the required hiding power;

- ensure viscosity at the level of 20 C;

- a 2-point surface adhesion indicator;

- ensuring the thickness of the coating from 60 to 100 microns;

- the ability to operate at temperatures from -60 to +300 degrees.

The technical passport also indicates the requirements for the condition of the surface to be painted. It must be completely cleaned, metal structures must additionally be treated with a degreaser.

Material consumption calculator per square meter

When working with paints and varnishes, the calculation of the amount of funds is important. Please note that application methods may vary. In this case, the composition is traditionally applied in 2-3 layers. The thickness of a single-layer coating is 40-60 microns.

The calculations are based on the fact that the average consumption rate when applying a layer is 180 g per m2. In order for the paint consumption not to exceed the limits of the calculations, it is necessary to follow the rules of work, depending on the selected application devices.

With pneumatic spray

Pneumatic spraying assumes special adjustment of paint equipment, taking into account standard rules.In order to correctly calculate the amount of paint that will be needed to paint the selected surface, the following application recommendations are followed:

- the distance between the gun nozzle and the surface to be treated should be 200-400 millimeters;

- inside the device, a pressure of 1.5-2.5 kilograms per square centimeter must be maintained;

- the diameter of the spray nozzle is 1.4-1.7mm.

Airless spray

When choosing an airless spray, observe the following guidelines:

- the distance from the nozzle to the surface is 350 millimeters;

- the pressure of the material inside the device is between 80 and 140 bar;

- the diameter of the spray nozzle does not exceed the limits of 0.38 to 0.58 millimeters.

Manual application

When coloring by hand, use brushes and rollers. In this case, the paint consumption may exceed the calculations. The brush should be made of natural fiber, it is recommended to choose a roller with short bristles or without bristles.

Stripe Dye

Difficult-to-reach parts, joints, seams are covered by the tape-dyeing method. The rinse is used before the main coloring; brushes or rollers with long or short handles are used for this. Stripe coating can increase the amount of paint used if the surface has many ridges or indentations.

Application technology

Painting works with organosilicate compositions usually do not require preliminary priming of the surface, but when using OS-12-03, a primer is required. Application of an enamel-compatible primer mixture improves adhesion and enhances the protective properties of the finish.

Coaching

When working with paints, the correct preparation of the treated surface is important.It must be cleaned of traces of oils, salts, dirt and dust.

Separately, the surface is examined for the presence of rust spots. If small marks are visible in areas prone to corrosion, they should be cleaned.

If traces of old enamel remain, use scrapers, spatulas or special devices. If painting is planned over a large area, sandblasting is carried out.

To remove rust stains from the surface, special converter-strippers are used. Treatments are performed up to 5 times to completely remove stains. Corrosion converters act as rust thinners. After surface treatment, the solvents are left to stand for 30 minutes. A substance gradually appears on the object, which is formed as a result of the reaction between the elements. It is a white, frothy liquid. It is washed off, the surface is dried.

After removing traces of dirt from metal structures, degreasing is carried out. This includes treatment with special compounds, which are purchased additionally. Degreasing prepares the surface for subsequent painting, it helps to create optimal conditions for adhesion between coats and increases the protective qualities of the finish created.

Primer

The next step is to apply a primer. To impregnate concrete surfaces or treat reinforced concrete structures, use FL-03K primer. The product is applied in one layer using special tools.

Additionally, they practice using a fast-drying primer designed to adhere to organosilicates. It is a mixture created with the addition of organic solvents. The quick-drying primer for metals is used in mechanical engineering, shipbuilding, railway or agricultural machinery construction.

The primer layer additionally protects the coating from corrosion, promotes good adhesion between paints and varnishes of the main type of application and is resistant to external influences.

Attention! The primer is applied from a spray gun in a thin layer, then it is planned to dry before proceeding to the main work.

Painting concrete and metal surfaces

The optimal choice when painting concrete and metal structures involves the purchase of a special device - a paint sprayer, with which you can work independently.

Recommendations for the application of OS-12-03:

- for spraying, the tip of the nozzle is kept at a distance of 200 to 400 millimeters;

- seams, edges of parts, protruding ends are treated with brushes;

- metal products are painted in 3 layers, concrete products are painted in 2 layers, above ground;

- time intervals are maintained between drying layers;

- each layer is checked for peeling;

- the final polymerization is facilitated by the creation of special conditions, that is to say by the use of the hot drying process;

- hot drying involves a gradual increase in temperature by 1-2 degrees;

- when painting parts in an aggressive environment, the surface is pre-cured at temperatures from +250 to +400 degrees for 15 minutes.

Stir the paint well before staining. There should be no sediment on the surface. After reaching a homogeneous composition, the paint is kept for 10 minutes so that the bubbles completely disappear from the surface.

To properly dilute the working fluid, use the solvents toluene or orthoxylene. It is strictly forbidden to dilute organosilicates with white spirit or gasoline.During drying breaks, the organosilicate enamel is stored under a tightly closed lid in a cool room.

Final coverage

The need for final staining is assessed individually. After applying two or three coats, the film created may not be strong enough.

When planning work, it should be borne in mind that the composition reaches the final coating under natural conditions only after three days. If there is a low air temperature outside, the period increases to 14 days.

Painted structures can be transported or erected 24 hours after application of the topcoat. Until the structures are completely dry, an additional coat of paint can be applied depending on current requirements.

Advice from the masters

Working with organosilicate compositions requires certain skills and abilities. This is a complex manipulation in which it is important to respect safety measures. Due to the presence of solvents, the products remain toxic until the vapors disappear from the treated surface.

To avoid harm to health, you must fully protect the respiratory system and wear special protective gloves or gloves. It is imperative to wear tight clothing on the body. After work, all products that have been used should be washed until the substances are completely removed, then left to dry naturally.

Tips and tricks:

- Experts advise to completely clean the defects when applying paint to a concrete surface. Thin notches are leveled with a putty, and suitable mixtures are used to seal the grooves.

- New concrete surfaces should not be painted until 28 days after release from the structure.This is because new concrete surfaces contain an increased amount of structural moisture. Release of moisture to the exterior may interfere with the creation of a durable elastic coating and violate OS-12-03 rules for use.

- It is unacceptable to paint metal surfaces that are not cleaned to the second degree according to technical standards.

- Degreasing of metal surfaces can be done with agents such as toluene, xylene or acetone. The use of white spirit or gasoline is not recommended.

- When processing masonry, deadlines should be taken into account. Experts do not recommend painting brick facades within a year after installation.

- It is not recommended to apply the composition in less than three layers, while the first layer is considered a primer.

- The shelf life of the paint from the date of production without loss of quality is 12 months. During transport and storage, a closed container should not be frozen and thawed. This technique will worsen the quality characteristics of paint and varnish.

- The speed of drying of the created layer depends on the method of application, this must be taken into account when planning work. If the material is applied by roller, the drying time does not change, it is 3 hours, which are declared by the manufacturer. If the paint is sprayed using a gun, the drying time is reduced to 1 hour.

- Drying time and curing time are different concepts. Drying refers to the initial adhesion between layers with the hardening of the top film. Polymerization is a long-term curing process for all layers of the coating created. It takes several days.

Subject to the rules when working with enamel OS-12-03, the period of operation is 10 years. When the optimal conditions for the use of paint are created, it is extended for up to 15 years.