8 types of primers for plywood and a rating of the best brands, rules of application

Plywood is a common material that is actively used in the production and construction of furniture. An untreated surface does not look very attractive. Therefore, it is recommended to decorate it. It is recommended to properly prepare the plywood sheets before applying varnishes and paints. For this, use a special plywood primer.

Primer for plywood: varieties and properties

For application on plywood it is allowed to use different types of primer. Such mixtures contain film-forming components - adhesive mixtures, oils, polymers, special additives.

Each brand offers a unique primer formula, adding fillers that provide quick drying, viscosity, and other characteristics. Also, manufacturers can introduce coloring pigments and bactericidal additives.

Depending on the base, there are oily, acrylic, alkyd, mineral compositions. Surfaces treated with different types of soils differ in their characteristics during operation. Therefore, before purchasing a particular mix, it is important to determine the desired surface properties.

Acrylic

This primer is made on the basis of acrylic. That is why the composition has the best characteristics inherent in acrylic dyes and impregnations. The composition forms a protective film on the surface and penetrates into the pores and cracks of the sheets, creating an additional protective layer on them. These properties can be enhanced by coloring. For this, it is recommended to use special paints and varnishes that are compatible with the primer.

The advantages of the material are:

- fast drying;

- lack of pungent odor;

- creation of a protective film on the surface of the plywood.

At the same time, the material also has some disadvantages:

- high soil consumption;

- the presence of harmful components in certain mixtures.

alkyd

These primers work well on untreated plywood. On wood, they help create the perfect finish. Thanks to the formation of the film, it is possible to strengthen and protect the base. As a result, it is possible to achieve a uniform application of paints and varnishes. Alkyd compounds are considered a good impregnation. They can be applied in one or more coats as desired.

The advantages of alkyd floors are:

- uniform application;

- creation of a protective film;

- impregnation of plywood sheets.

At the same time, the materials also have disadvantages:

- long drying period;

- strong toxic odors.

Drying oil compositions

Such funds are distinguished by pronounced moisture protection properties.Thanks to this, they protect surfaces from liquids.

The advantages of the material are:

- water-repellent properties;

- application versatility.

At the same time, primers also differ in their disadvantages:

- toxic components in the composition;

- Strong smell.

phenolic

These primers are most often used for the treatment of plywood sheets in the furniture industry. They are characterized by high impregnation characteristics and an affordable price.

On average, it takes 10 hours to dry completely.

The advantages of the material include:

- application versatility;

- high absorption capacity;

- affordable price.

However, there are also disadvantages:

- relatively long drying time;

- the danger of phenol to human health.

Shellac

It is a great option for different types of wood surfaces. It is allowed to use such primers as impregnations before using varnish. For the production of shellac compositions, milky insect juice is used.

Primer benefits include:

- high efficiency;

- the possibility of using as an impregnation;

- safe composition.

In addition, the material also has disadvantages:

- high price;

- high consumption.

Epoxy and polyurethane

These products are made on the basis of polyurethane and epoxy resin. Before using them, it is important to carefully read the instructions for use.

The advantages of such formulations include:

- resistance to the influence of external factors;

- economical consumption;

- high strength and durability.

At the same time, the floor also has different disadvantages:

- the presence of toxic components in the composition;

- high price;

- long curing time.

Styrene

Such mixtures lead to the formation of a film on the surface of the plywood. They provide reliable protection of materials against mold and rot. Compositions can be combined with phthalic and alkyd enamels.

The benefits of the substances include:

- creation of a protective film;

- protection of materials against mold and rot;

- compatibility with different types of enamels.

However, there are a few drawbacks:

- high price;

- harmful components in the composition.

Nitrocellulose varnish

This type of varnish is often used as a primer. It is perfect for woodworking.

The benefits of coverage are:

- fast drying;

- good adhesion to the surface;

- high resistance to moisture;

- ease of application.

In this case, the substance is also distinguished by disadvantages:

- risk of detachment;

- the presence of combustible components;

- low wear resistance.

Principle of operation

Plywood primers have a whole range of useful properties. Thanks to their use, it is possible to obtain the following effects:

- Increases the resistance of wood sheets to the destructive action of moisture, reduces water absorption by wood, prevents swelling and deformation. With the subsequent application of water-repellent paints and varnishes, the water resistance of the material increases.

- Prevent coating rot. Plywood primers have antibacterial properties. Thanks to this, it is possible to avoid rotting of the coating.

- Prevents cracking of wood.

- Protect plywood from mold and mildew. This result can be obtained thanks to specific additives in the soil.

Recommendations for choosing primers for plywood surfaces

For wood priming to be successful, it is important to choose the right mix.In this case, it is recommended to take into account a number of characteristics:

- The chosen primer should be suitable for application to plywood and wood surfaces.

- The composition must be combined with the dye.

- It is better to choose a primer with special antibacterial ingredients. This will help protect the surface from the appearance of mold, rot, fungus.

- When processing the surface in fresh air and subsequent exposure to direct sunlight and precipitation, preference should be given to primers with water-repellent characteristics.

- It is also necessary to use a water-repellent primer if the rest of the finishing materials have such qualities.

- For application on plywood, it is permissible to use the same composition as for chipboard.Thanks to the use of the material, it is possible to increase the degree of adhesion with paints and the base.

- When choosing a primer mixture, you need to focus on the level of humidity in the room.

- It is recommended to use alkyd or hydroacrylic compounds for priming plywood.

- It is allowed to use nitrocellulose paints NTs-48 or NTs-1227 as a primer.

By constituent components

Usually all primers contain film-forming components - oils, polymers, adhesives, special additives. Each manufacturer uses a unique formula. As a result, soil may contain the following substances:

- fillers - provide quick drying, viscosity and other special characteristics;

- coloring pigments;

- bactericidal components.

According to the base, the compositions are oily, acrylic, alkyd, mineral.During operation, surfaces that have been treated with different soils exhibit different properties. Therefore, before purchasing a composition, it is important to determine the desired surface properties.

In this case, the following characteristics should be considered:

- When purchasing flooring, it is important to ensure that it is suitable for plywood. Equally important is the presence of the same base as the paint.

- Acrylic dyes are more suitable for residential premises. They dry quickly and are almost harmless. These substances do not have strong odors.

- It is allowed to use enamels on the outside. They dry quickly, but have a strong smell and toxic properties.

By material properties

When using the substance in a room with high humidity, it is important to select the correct composition. The primer must simultaneously meet two requirements - have antiseptic properties and protect against moisture.

It should be borne in mind that the use of waterproof plywood does not dispense with the use of a primer. This is especially true for cutting sites. In addition, a well-chosen composition makes it possible to increase the adhesion of the final coating and reduce the cost of paints and varnishes.

Plywood used outdoors requires more complex primers. They should contain antiseptic ingredients to protect against disease and parasites, and contain water-repellent ingredients that minimize the negative effects of precipitation. The most optimal primer options for external surfaces include epoxy and polyurethane compounds.

Ranking of the best primer brands

Primer mixtures today are produced by many brands. Their assortment includes products that can be used for plywood application:

- Pufas - the brand offers a versatile composition that has excellent vapor permeability. It is allowed to use it for finishing external and internal surfaces. The primer is perfect for rooms with high air humidity. It is also allowed to use it for the treatment of facades. The composition contains fine quartz sand, which creates a rough substrate and increases the degree of adhesion.

- Pinotex base - designed for application on wooden facades and plywood sheets. This soil spreads evenly. In addition, it contains fungicidal components that provide reliable protection against wood rot and the appearance of fungus. It takes 1 day to dry the coating. After its application, a matte decorative film appears on the surface.

- Tikkurila Valtti Expert Base - This Finnish brand offers a perfect primer for application on plywood and wood. The material has excellent penetrating properties. Thanks to this, it allows you to process surfaces with a moisture content of up to 40%. The substance helps to even out the absorbency. After that, the paint lays down evenly and does not form spots.The material contains fungicidal substances. They provide reliable protection against fungus, rot and mold.

Features of work with material

When priming plywood sheets, it is important to choose the right materials and strictly follow the rules for applying the primer. Most often, the procedure is carried out for painting.

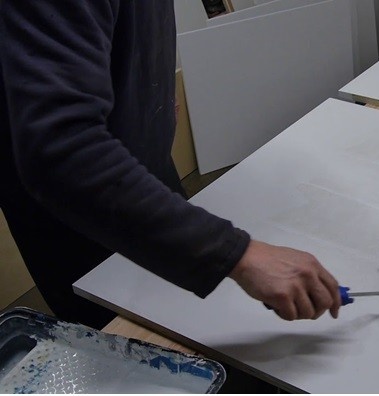

Necessary tools and calculation of soil consumption

To apply the primer, the following items are required:

- sprayer - helps to manage large areas;

- roller - allows priming medium-sized areas;

- A paintbrush is a versatile tool that should be used for hard-to-reach areas.

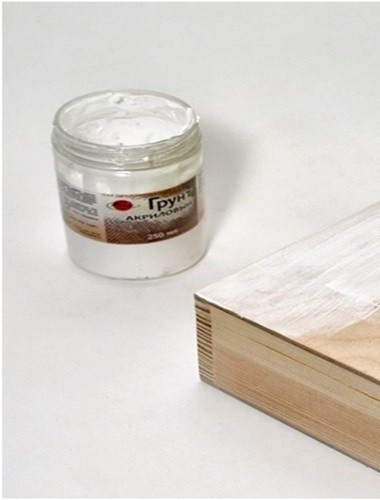

Surface preparation

Since plywood sheets are often sold unpolished, they must be prepared for the application of a primer. First, the surface must be cleaned of dust. Then it is allowed to proceed to grinding. The procedure must be carried out manually or using a grinder. For this, a P80 or P100 grit sandpaper is perfect.

Layers should be removed in a direction perpendicular to the main structure. Then it is worth using fine sandpaper to achieve full smoothness. In this way, it is recommended to process the main surface of the sheet and the edges. At the next stage, it is allowed to proceed with the application of primers.

Application technique

Plywood is easy to prime. It is important to apply the coats evenly in order to achieve a neat result. It is important to keep them as thin as possible. Otherwise, there is a risk of burrs which will alter the appearance of the material. If the plywood is thinly primed, it will give the dye a brighter, more intense shade.

It is allowed to apply the primer mixture in 2 layers. This will help increase the strength of the coating. It is important to take into account that it is recommended to apply the second layer only after the first has completely dried.

How long does the coat dry?

The drying time of the coat depends on the plywood on which the primer is applied and the number of times it is applied. The dry, porous base is able to absorb all the liquid at once. In such a situation, it is permissible to carry out the second treatment almost immediately.

The drying time also depends on the composition of the primer.The humidity and temperature parameters are not negligible. On average, it takes 4 hours to 1 day to dry 1 coat. However, the exact duration of this step can be found on the packaging.

Errors when working with the material

When using primers, many novice craftsmen make certain mistakes:

- choosing the wrong soil composition;

- the process of preparing the surface for applying the substance is neglected;

- violate the drying time of layers.

All these factors significantly reduce the strength parameters of the final coating and make the primer layer uneven.

Recommendations from the masters

To prepare high-quality plywood sheets, it is recommended to follow the basic advice of experienced craftsmen:

- Pay special attention to the choice of primer. It must be adapted to the type of surface and the conditions of use. Not inconsiderable is the compatibility of the floor with paints and varnishes, which are intended to be used for further finishing.

- When using the material in rooms with high humidity, it is worth using a primer with special antifungal additives. Thanks to this, it is possible to avoid the appearance of mold and fungal microorganisms on the surface of the plywood.

- Pay attention to the ends of the material. This helps to increase its strength and prevent plywood sheets from swelling.

- After applying the primer, the plywood must be painted. When using the material in outdoor conditions, it is worth using oil-based dyes or pentaphthalic enamels.In this case, it is important to repeatedly paint over the edges. If you plan to use the product indoors, a water-based paint - for example, acrylic paint, is suitable.With proper surface preparation, the colorant will deposit easily and adhesion will be maximized. Additional advantages include the absence of unpleasant odors and a short drying time.

- To give the surface a shine, a varnish should be applied to the painted plywood. It is better to use a spray gun in this case. Thanks to this device, it will be possible to achieve the most even coverage. It is also allowed to use a lint-free roller. It is recommended to paint hard to reach areas and sides with a brush.

Properly selected plywood primer helps to significantly increase the strength parameters of the material and ensure its protection against the negative influence of external factors. To achieve the desired effect, you should pay attention to the composition of the mixture and follow the recommendations for its application.