Description of types of glue for strong fixation of threaded connections, rules of application

The wire adhesive is very effective. This tool is used quite often. It is applied to the threads to fill in the gaps. This prevents gas or liquid leakage. Also, the substance prevents corrosion of metals. The composition is produced in different forms - in the form of a liquid or a thread. Thanks to this, each master can choose the best option.

Types and features of wire clamps

There are many types of thread locking compounds. Thanks to this, it is possible to choose the right product.

linen thread

Flax is actively used for winding pipes. It is used for all metal parts - brass, steel or cast iron. It is also allowed to use flax in areas where metal wires are welded into plastic.

On all-plastic elements, such a wire is not used, since it requires strong clamping. As a result, there is a risk of yarn breakage.

plumbing thread

This is a great hose reel option. This thread has only one drawback - its high cost. It can be used to seal all joints, including plastic.

FUM Ribbon

The product is not used as a pipe sealant. At the same time, the tape is suitable for use in a summer cottage and in a vegetable garden, since there is no danger in such places due to small water losses.

sealant

Different types of sealants can be used to secure and seal threads. This allows you to choose the right product.

Not hardening

These putties are produced in the form of a viscous paste. They contain resins and polymers. The thick mass provides excellent sealing without loss of quality characteristics due to vibration.

Putty will not fix the threads. Such a tool completely fills the gaps, ensuring good sealing of the structure. The composition is completely safe. It can be used for pipes with water.

This type of paste is not recommended for use with constant high pressure on the pipes.

In this case, the substance will be expelled, causing a leak. It cannot be prevented. In such a situation, a different composition is chosen.

Hardening

Such products are characterized by high strength. In addition, they take a long time to dry. It depends on the quality characteristics of the substance. This is the only downside of a hardening putty.

It is recommended to wait after using the composition. The specific time period is indicated on the packaging. Only then is it allowed to start mining or carry out further work.

This type of sealant reacts normally to pressurized water supply. After complete curing, it cannot be moved. It is allowed to choose compositions of different levels of fixation. It determines the strength and torsional strength of the pipe.With a small degree, the product can be disconnected manually, with a strong - this is done by breaking, after heating.

Anaerobic

This is an innovative type of putty. They are used by professionals and amateurs. The principle of operation of the composition lies in the crystallization of the substance after application.

When exposed to air, the substance retains a liquid consistency. In this case, contact with air causes a chemical reaction. As a result, the substance acquires the consistency of an adhesive. This makes the attachment area monolithic.

Loctite

This putty has a long service life and high strength. It is sold in the form of liquid mass and threads.

Anaterm

The product has similar properties. It is allowed to use it to fix various parts and eliminate cracks.

Plumber

The substance is suitable for threaded and flanged structures. It is resistant to the influence of alcohol, chemicals, high temperatures. The composition prevents corrosion and does not contain harmful ingredients.

Sealing gel

This gel is generally used for cars. The composition helps to strengthen the thread. Gels provide joints with resistance to vibration, temperature and mechanical factors. To separate the structural elements, it must be heated.

Characteristics of the glue for threaded connections

In order to choose the right adhesive for fixing the wire, a number of parameters should be taken into account.

Compound

The components in the composition of the glue can be different - it all depends on its type. So, non-hardening sealants are made on the basis of resins and polymers.

Strength

Strong hold sealants cannot be unrolled. In this case, it is enough to break the thread.When using a low-strength substance, it will be possible to untwist the connection with minimal effort. With an average degree of fastening, additional tools will be required.

Viscosity

For closing small seams, it is recommended to use a paste in the form of a paste. If you need to seal a large seam, then a liquid mass will be needed. The larger the surface, the more fluid the composition should be. The mixture will get into hard-to-reach places, helping to fully hold the seal.

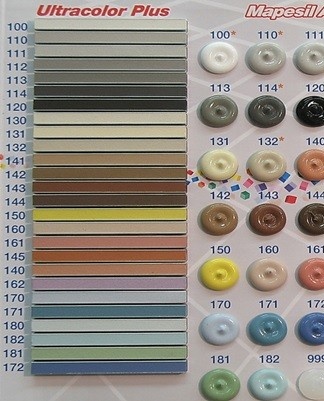

Color

It is allowed to choose compositions for sealing, taking into account the color scheme. The shades depend on the manufacturers. Popular colors are as follows:

- Red. The company StopMaster is engaged in the production of such putty. The substance polymerizes quickly - it takes no more than 5 minutes. The sealant is considered anaerobic. It is best used for black metal pipes.

- Green. The tool is sold by the company Santekhmaster. The composition is characterized by low fixation. After polymerization, it will be possible to unscrew the thread only with a key. The composition is suitable for pipes with a maximum diameter of 1.5 inches.

- Blue. The composition is made by the Santekhmaster. This gel is specially designed for threaded elements. The tool is versatile. It is used to seal metal or plastic elements. Polymerization takes a quarter of an hour. It is allowed to work with the composition at a temperature not higher than +15 degrees.

- White. It is a versatile compound commonly used for plastic pipes. They also fix metal fragments of small diameter.

- Orange. This tool is manufactured by Scotch-Weld. It is used for automotive repairs.The composition adheres tightly to the threads. To separate the elements, they must be very hot or broken.

- YELLOW. Putty is available from QuickSpacer. The product is made for metal and fittings. The curing process is extremely slow. The composition can be used at a temperature of + 10-40 degrees.

Setting time

This parameter is usually indicated on the packaging with the substance. Cure rates are determined by many factors, including the quality of the material and the environmental conditions that affect the joint. It is permissible to use pipes after the expiration date. Otherwise, there is a risk of depressurization.

Use a threadlocker

The composition should be selected taking into account the required technical properties. In this case, it is worth taking into account the composition of the pipe, the material, the safety parameters and the period of polymerization.

Some substances should not be combined with water, others with gases or fuels, as indicated on the sealant packaging.

The application of the substance has the following characteristics:

- first of all, the surface must be cleaned of dirt and rust;

- carry out degreasing;

- apply a thick layer of sealant to one part, then fix the joint.

Advantages of bolt glue

The use of fixing bolts for work implies ease of application. This is facilitated by the packaging and the liquid consistency of the substance. In addition, these formulations are distinguished by the following characteristics:

- joints created using these compounds are not subject to displacement or shrinkage;

- the use of sealants helps to protect the threads from corrosion;

- a variety of substances makes it possible to use them on bolts of different diameters;

- sealants help prevent loosening and provide vibration and shock protection to joints;

- the low viscosity of the formulations helps them to penetrate the smallest gaps between the parts - this increases the reliability of the fastening.

Disadvantages of plumbing glue

Any glue has certain disadvantages:

- When using strong compounds, it will not be possible to untwist the thread manually. For this, it is worth using special tools or heating.

- It is worth choosing glue for the water supply taking into account its safety. Some substances contain harmful components.

- Quick adjustment makes it impossible to change the position of bolts and nuts. You cannot put the glue back in liquid.

- You should not use this method at low temperatures, as the solidification period becomes quite long.

How to work with yarn glue

When working with such glue, the following rules must be observed:

- clean and degrease the wire;

- determine the quality of the metal;

- apply glue;

- eliminate excess substance;

- wait for the composition to polymerize.

How to Remove Thread Sealant

If the sealant has a weak fixation, it will be possible to unscrew the joint with a key. At a medium degree, it will take a little more effort. At the maximum level of fixation, the mastics are first heated and then rolled out. Generally acceptable disassembly methods are indicated on the packaging.

Wire glue is very effective, helping to hold even complex items together. To achieve good results in fixing products, you need to properly prepare the surface and follow the rules for applying the substance.