Types of transparent adhesives for bonding glass to metal and how to use it at home

The strength of the joint created depends on the quality of the adhesive selected. It is especially important to take this into account when it becomes necessary to combine glass and metal objects. For such materials, you need to select special compositions. Transparent adhesives for glass and metal should be characterized by increased adhesion, thanks to which the maximum bonding strength is achieved.

Basic Adhesive Requirements

Glass has three qualities that interfere with the adhesion of parts made of this material:

- poor adhesion;

- increased fragility;

- transparency.

Adhesives used to join glass products must create not only a strong joint, but also a transparent one. Otherwise, the hitch point will be visible on the bottom of the material.However, not only these qualities should characterize the selected adhesive. For glass and metal, it is recommended to select a composition with the following properties:

- viscous;

- sets quickly;

- resistant to temperature extremes and high humidity;

- safe for humans;

- elastic.

Such qualities are characteristic of expensive adhesives. But it is not recommended to save on such materials.

Strength

This indicator is considered the most important. The durability of the joint created depends on the strength of the bond. For glass, it is recommended to purchase adhesives that adhere tightly to parts when exposed to ultraviolet light. The seals obtained in this way are able to withstand increased loads.

Waterproofing and moisture resistance

Some glass and metal products often come into contact with water. Therefore, for gluing such materials, it is recommended to purchase adhesives that have the properties of a putty.

The characteristics of this composition do not change with prolonged contact with moisture, and the created seam does not let water through.

Solidification rate

This parameter does not play a determining role. However, the curing rate of the adhesive should be considered when choosing a product. Quick-drying materials harden in seconds, which is why it is necessary to immediately and accurately connect the glass parts to each other.

What varieties are suitable

The range of adhesives is extensive. But a limited list of such compositions is suitable for working with glass and metal. Polyurethane, cyanoacrylate, silicone and a number of other adhesives are suitable for joining products made from these materials.

Two component epoxy

Polyurethane adhesives, depending on the type of ingredients included in the composition, are divided into one- and two-component. The first variety is relatively popular, since it does not require preliminary preparation and dilution of the constituents of the material.

Two-component polyurethane adhesives are considered preferred for bonding metal and glass.

These compounds provide a strong connection, but harden more slowly than the first, so that, if necessary, the parts to be fastened can be applied more precisely. These adhesives contain resin and active substances that determine the degree of viscosity, drying speed and other characteristics.

heat resistant silicon

Heat resistant silicone adhesives are used to repair glass that is constantly exposed to high temperatures. This includes materials used in ovens and other similar household appliances. The heat resistance of the adhesive is provided by individual components that are added to the initial mix.

The disadvantage of silicone is that it takes longer to harden. But these sealants tolerate long-term contact with fats and oils, as well as exposure to negative temperatures.

instant crystal

This product is suitable for gluing:

- glass;

- porcelain;

- metals of various types;

- PVC;

- drink;

- plexiglass.

Moment The crystal is transparent and solidifies rapidly. This product is not recommended for bonding items that come into contact with food. Moment Crystal is suitable for creating seams subject to increased stress.

Auto

Automotive adhesives are characterized by increased adhesion and resistance to aggressive substances. This type of material creates seamless seams. Such compounds are also available in different colors, so any car parts can be glued. To create a strong seam, it is recommended to additionally warm the seam.

Cyanoacrylate

Cyanoacrylate, depending on the type of ingredients included in the composition, can be one-component or two-component. Both types of glue dry quickly: the joint hardens in 5 to 10 seconds. Some cyanoacrylates are not resistant to humidity. You should pay attention to this when buying.

sealant

High-quality sealants are not inferior to heat-resistant silicone adhesives. These materials are also able to withstand sudden temperature changes (including up to +300 degrees), contact with water and fats. It will take at least a day to completely dry the sealant.

How to stick at home

The strength of the connection of materials depends not only on the quality of the purchased glue, but also on the condition of the base. The latter is recommended to be degreased and cleaned of dirt before starting work.

Preparing the base for bonding

Each base should be cleaned of dirt, rust and moisture before bonding. The metal should be wiped with a choice:

- acetone;

- White spirit;

- alcohol (vodka).

These fluids remove grease, thereby increasing the adhesion of the material. The glass should be cleaned with an appropriate detergent and dried. If there are traces of paint or varnish on the metal, these materials must be removed with a grinder or sandpaper. After the procedure, the base should also be degreased.

Work steps

To reliably glue glass and iron, it is necessary to warm both components to 40-50 degrees. For this, it is recommended to use a building hair dryer. In contact with an open flame, the glass cracks. When heated, the remaining moisture is removed, thereby increasing the level of adhesion of materials.

After that, you need to apply glue to the parts and level the composition, forming a thin layer.Then the components should be bent together and pressed tightly under the press. It is recommended to immediately remove the escaping adhesive. Otherwise, in the future, visible stains will remain on the treated materials.

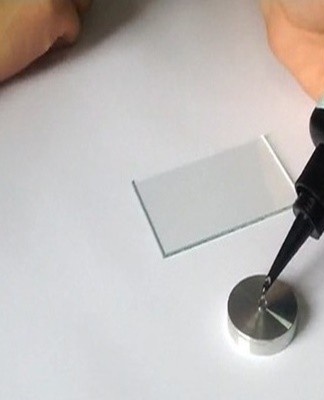

UV lamp application

Under the influence of ultraviolet radiation, the strength of the seam increases. Before gluing, the parts should be heated to 60 degrees. After connecting the components along the seam, you need to run it twice with an ultraviolet lamp. After the initial exposure, the strength level of the adhesive composition increases by 70%, after the second - by 100%.

Features of working with aluminum

For bonding aluminum, specialized compounds are suitable, including methyl acrylate, acids and alkalis. The latter split the oxide film which constitutes the surface of the material. Thanks to these components, the level of adhesion of the parts is increased. The algorithm for bonding aluminum to glass is the same as the one given above.

Additional tips and tricks

To firmly bond the glass to the metal, it is recommended not only to hold it twice with an ultraviolet lamp, but also to hold the latter in the joint area for two to five minutes. When working with the described formulations, protective goggles should be used. The glue must be applied with a brush. In this way, you can achieve an even distribution of the solution on the surface.

If you buy a two-component glue with a hardener, you need to open the window during operation. Polymer compounds cannot be used to repair products that come into contact with food or water.