Description and properties of polymer glue, varieties and application instructions

Today, polymer adhesives, which are used in various economic areas, are especially popular. Before using such an adhesive, you should familiarize yourself with the description of its features and application features.

General description and properties of polymer glue

It is recommended to understand the general description and properties of adhesive liquids based on polymers.

Water resistance

One of the advantages of such adhesives is that they are water resistant. Therefore, after application, a strong seam remains on the treated surface, which does not absorb moisture.Due to their water resistance, the mixtures are often used for exterior renovations. For example, they can be used to attach thermal insulation sheets for foam or polystyrene insulation.

Respect the environment

It is very important that the adhesive used is environmentally friendly. Mixtures based on polymers are considered completely safe, since their composition does not contain any toxic components. Such mixtures are made of antimony oxide, which prevents glue line fire.

To give the agent thermal conductivity, a little boron nitride is added to it.

Heat resistance

High-quality adhesive mixtures based on polymers are resistant to extreme temperatures. After drying, the glue applied to the surface withstands temperatures from minus fifty to one hundred and eighty degrees above zero. Such resistance to temperature changes allows you to use adhesive mixtures outdoors even in winter.

Frost resistance

Adhesive mixtures, in the creation of which polymeric substances are used, are well resistant to freezing. They do not lose their elasticity and do not crack after being applied to the surface, even when the temperature drops to 45-50 degrees below zero.

Versatility

Another significant advantage of adhesive mixtures is their versatility, due to which such means can be used for gluing various materials. Polymer compositions are used to work with wooden, ceramic, plastic, plastic, glass and even metal products.

Electrical conductivity

Such compositions for bonding various materials have high electrical conductivity. Electrical conductivity is ensured due to the fact that the composition contains a lot of metal particles. Also, in the manufacture of funds, special electrically conductive powders are used, among which one can distinguish graphite, palladium and silver.

Thermal conductivity

All polymer adhesives have an increased level of thermal conduction. This is due to the fact that when creating funds, a special substance is added - boric nitride. It is thanks to this component that the adhesives produced have thermal conduction properties.

Fire resistance

Many adhesives have a serious drawback due to their tendency to ignite. However, blends made from polymers are flame retardant.

They do not begin to burn under the influence of high temperatures due to the fact that special components are added to them to prevent this process.

Reliability

One of the main advantages of adhesives is their high reliability. The bonded materials are bonded so firmly that it will be impossible to separate them even by heating the adhesive joint. On average, the bond strength is maintained for ten years. After that, the seam begins to peel off.

Adjustment speed

People who choose their own glue often pay attention to such a property as setting speed. Polymer adhesives do not harden as quickly as other products. This allows you to correct the position of the materials to be bonded within 20-30 minutes after applying the mixture.

Fast drying

Polymer-based adhesives differ from most other products in their drying speed. After application, the seam dries completely within an hour.However, if the liquid was applied to a wet surface or under low temperature conditions, the solidification rate increases by one and a half times.

Varieties

There are six types of polymer-added glues that are most often used.

For interior work

Some funds are used only for internal work. Such mixtures have the following advantages:

- respect the environment;

- water resistance;

- ease of use;

- reliability.

However, they are not resistant to extreme temperatures and therefore cannot be used for outdoor work.

For outdoor work

Some people have to deal with the arrangement of the facades of apartment buildings. To do this, use polymer compounds suitable for outdoor work. They are often used to fix insulating plates, ceramics or mosaics.

Among the advantages of the glue is its resistance to low temperatures and high humidity.

Universal mixtures

Universal waterproof glue is used for exterior and interior work. It contains components that increase the frost resistance of products and make them resistant to high humidity. Also, the advantages include the balance between product quality and cost.

Mounting solutions

Sometimes you have to use special mounting solutions. They are used for bonding heavy products, fixing facade parts or forming chips. Such solutions are used not only in various industrial fields, but also in everyday life. Advantages of assembly tools include resistance to vibration, mechanical damage, and chemical exposure.

Liquid Nails

Liquid nails are a polymer adhesive solution suitable for bonding plastic, ceramic, glass, iron and plasterboard surfaces. The composition of liquid nails contains synthetic rubber, due to which the agent hardens faster. The mortar is very reliable, since only a small point application is enough to fix the materials.

cold welding

It is the least commonly used adhesive only for bonding wood, plastic, glass and clay surfaces. Most often, cold welding is used when it is necessary to glue a damaged or broken product.

For what work can you use

Before using polymer glue, you should familiarize yourself with the job for which it is best used.

Installation of parquet boards

Polymer-based glues are used in the laying of parquet boards, which are often laid on the surface of concrete screeds. When installing the parquet, the glue should be applied at an air temperature of about 20-25 degrees Celsius. In this case, the air humidity should be at least sixty percent. Only in such conditions will the panels be firmly fixed to the concrete surface.

Coating of various surfaces

Often, facing work is carried out outside the house, during which polymer glue is used. With its help, decorative stones, plasterboard, tiles, wooden boards and even metal cladding plates can be attached to the surface of the walls. To work with such materials, it is better to use universal mixtures.

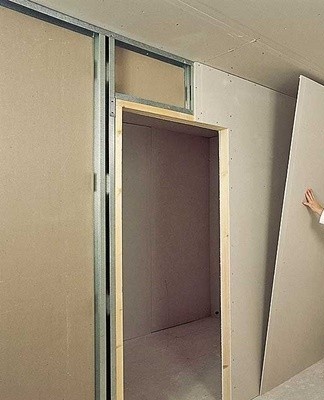

Fixing plasterboard

Some people think that drywall should only be attached to a metal frame, but that is not the case.Sometimes it is better to install them directly on the wall surface, without using an additional frame. In this case, a universal polymer adhesive is used to fix the sheets.

Minor repairs to furniture and household items

Often people are faced with minor breakdowns of household items or furniture. Sometimes it is impossible to fix them, but sometimes it is enough to glue the broken element together. To repair furniture with household items, you need to use adhesive solutions intended for interior work.

Creation and fixing of decorative elements

Polymer glue mixtures are often used for fixing facade decorative elements. For fixing decorative elements, compounds of a universal type are used, which are resistant to high air humidity and temperature extremes.

Fixing the ceiling cover

When carrying out repair work inside the premises, some people are involved in gluing the ceiling covering. For this, special plates are often used, which are attached to the surface with solutions containing polymer components.

roof

When building houses, the last stage is considered the arrangement of the roof, during which roofing work is carried out. A polymer adhesive is used in the process of laying the roof covering on the surface of the supporting structure.

Overview of manufacturers

There are four main manufacturers that produce quality adhesive solutions.

Dragon

It is a Polish product marketed by a Polish company that produces adhesives and construction chemicals. All products produced by Dragon are considered to be of high quality. That's why many builders use it.

"Hercules-Siberia"

This company specializes in the production of high-quality dry mixes from which liquid glue is made. "Hercules-Siberia" produces universal adhesives resistant to low temperatures and high humidity.

Axton

Adhesives manufactured by Axton differ from other formulations in quality performance. They are used during installation work, sealing joints, as well as when fastening metal or wooden structures.

bostik

It is one of the most renowned manufacturers of polymer-based adhesives. Bostik products are often used in the construction industry for exterior or interior wall cladding.

Application Instructions

Before using polymer products, you should read the instructions for use. The product is applied to a previously prepared surface. It is cleaned of debris, washed and degreased. This is done so that the glue more reliably adheres to the surface. If the adhesive is applied in high humidity conditions, the coating will also need to be primed.

Precautions for work

When working with glue, the following precautions should be observed:

- the work must be carried out with protective gloves;

- the working area is periodically ventilated so that there is no unpleasant odor;

- if the adhesive solution gets on the surface of the skin, it should be immediately washed off with warm water.

Additional tips and tricks

Before using glue, you should read the recommendations and tips for use:

- before application, the surface is carefully examined and checked for contamination;

- if necessary, clean it;

- the glue should be applied evenly, in a thin layer;

- after application, it is left to harden for 5-15 minutes.

Conclusion

Polymer glue is often used to bond various materials. Before using these funds, you need to understand their features, varieties, as well as recommendations for use.