Scope and consumption of foam-glue, the difference with the composition of the assembly

Many are familiar with polyurethane foam, but not everyone is familiar with foam glue. This adhesive has recently appeared on the market, but it is already popular with DIY enthusiasts. The special glue is packaged in cylinders. It is easy to use. It is easy to apply. Purpose - fastening of expanded polystyrene panels. They are used to insulate residential and industrial premises. Different brands of adhesives are on sale. Before buying it, you need to understand the main points of the choice.

Description and characteristics

Foam glue is a glue mass based on polyurethane. Polyurethane glue is a good alternative to cementitious seals used for fixing panels. Areas of application for foam adhesive:

- polystyrene insulation connection;

- fixing foam concrete;

- fastening of plasterboard;

- gluing of wood and stone coverings;

- reinforcement of window sills;

- insulation.

Adhesive foam is used to reinforce insulating surfaces. With its help, starter strips and boards are installed.It helps to fix the boards to the ground. Foam glue is used to fix expanded polystyrene insulating materials on various substrates: ceramic tiles, concrete, bricks.

main Features

Polyurethane adhesive foam is a modern material. It allows you to fix foam panels, perform external and internal work. The fastening made by him is durable and reliable. The adhesive provides durability and a high quality finish.

Main technical characteristics of foam glue:

- High adhesion. This quality ensures excellent adhesion of dissimilar bodies.

- Moisture and water resistant. Allows the use of foam glue for exterior and interior work.

- Good thermal insulation. This is an added bonus when insulating the facade and walls of the building.

Among the ingredients of foam-glue there are no toxic substances, no freons. This suggests that the adhesive is completely harmless to human life and health.

What is the difference with polyurethane foam

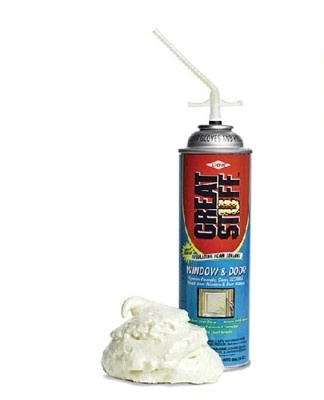

Polyurethane foam or foam glue? It is difficult for an uninformed person to understand it. To understand the difference between these materials, you need to compare them. Polyurethane foam is a polyurethane sealant. Purpose - installation. In addition, it has sound and thermal insulation properties. Used when installing doors, filling gaps, sealing joints. It can be used to fix building materials, but the expansion it gives on solidification makes fixing problematic.

The adhesive foam is a polyurethane glue. Its main function is to connect parts. It differs from polyurethane foam in its qualities.Its adhesive capacity and adhesion are several times greater than that of polyurethane foam. This is achieved through special additives. Adhesive foam does not expand. The volume increase is minimal. In order to evenly glue the panel to the wall with mounting foam, additional fastening is required. Otherwise, the foam, expanding, will lift the tile. When working with foam glue, no fasteners are needed. The panel is simply attached to the wall and pressed.

An adapter tube is included with the foam. Foam glue is a professional building material. You need a gun to use it.

Advantages and disadvantages

Foam glue has its own pros and cons. Benefits of foam adhesive include:

- Economical - one cylinder is enough for 12 meters.

- Convenience - the adhesive is sold ready to use.

- Ease of use. The glue is applied from a balloon. Leftovers are cut.

- Speed. The glue hardens much faster than polyurethane foam.

- Minimum magnification.

- Excellent adhesion.

- Respect the environment. There are no harmful substances in the composition.

Disadvantages include:

- high price;

- the need for additional devices - glue foam is supplied by a construction gun.

The advantages of foam glue successfully cover all its disadvantages. It is much better and more reliable to glue foam panels with them than polyurethane foam.

Choice criteria

When choosing a glue foam, you should pay attention to the working qualities. The adhesive is used for interior and exterior use. This suggests that it must prevent heat transfer. Speed is important for working. The sooner the composition is finished, the sooner you can continue to finish the job.Styrofoam adhesive should have good adhesion. The better the grip, the better the performance. An equally important quality is consistency. The distribution of the glue on the surface largely depends on the consistency.

Consistency

Consistency is the state of liquids and solids, determined by their density. High-density substances are distinguished by their density. When gluing, this disrupts the proper distribution of the composition and increases its consumption. A low density substance will spread. This will make the work poor quality. A good glue foam is characterized by a light consistency, medium thickness and density when solidified, about 25 g/cm3.

Vapor tightness

Vapor permeability is the ability of a material to transmit or retain water vapor. Quality is very important for building insulation and decoration. If the finishing material is vapor permeable, this poses a threat to its fragility. The deposition of water vapor on the surface leads to the formation of mold. The best option is a moisture-repellent material, on the surface of which condensation does not accumulate. Many adhesives have this quality. Foam glue is no exception.

Frost resistance

Freeze resistance is the ability of a material to withstand repeated freezing and thawing. In construction, this parameter is used to assess the preservation of the operational properties of the material under the influence of humidity and low temperatures. Glue foam has this quality to the fullest. It can withstand extreme temperatures for many years.

Composition requirements

The composition is of great importance in assessing the quality of building materials.Not only the operational capabilities depend on it, but also the health of people. Adhesives should be odorless. In their composition, the presence of toxic substances is unacceptable. The composition of polyurethane glue should not contain carbon dioxide and freon. These substances are harmful to health.

Setting period

The setting time is an important working parameter for the adhesive mass. The speed of work depends on it. The setting period is understood as the time between the assembly of the parts and their initial engagement. The setting time of the foam glue is 10 to 15 minutes. This is a relatively short period of time.

Coupling level

When gluing, the glue particles penetrate the two materials, connecting them. Glued materials are a kind of sandwich, in the middle of which there is an adhesive composition. Substances are added to the adhesive foam that increase its surface energy and help moisten the working surface. For this reason, foam adhesive is widely used for fixing various materials.

Overview of brands and manufacturers

In construction stores, adhesive foam from various manufacturers is sold. Samples differ in price and quality. The highest quality, but also the most expensive options are produced in Germany and Finland. It's really not worth buying glue foam made in China. But between these manufacturers there is still a wide range of products from other suppliers.

T-Vanguard

T-Vanguard combines expanded polystyrene with concrete and brick. It can be used to put insulation on a wall covered with plaster putty. The formulations are available in seasonal versions. They differ in the requirement of temperature conditions. The disadvantage of the adhesive is that it is sold in powder form.Before use, the glue is diluted with water.

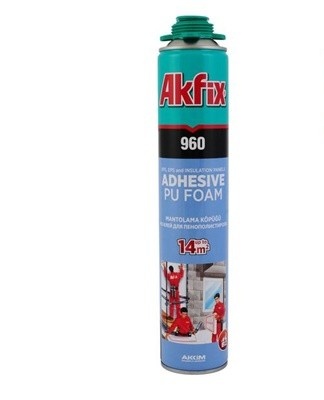

Tytan Styro 753

The glue-foam is packaged in cylinders. A distinctive feature is quick setting and complete drying. You can continue grinding and other installation work a few hours after laying the plates.

Ceresitis ST 83

Ceresite is sold in sachets. It is a powdery mixture. Package weight - 25 kg. The powder is diluted with water. Dilution instructions are on the package.

TechnoNIKOL

TechnoNIKOL adhesive foam is used for fixing XPS and EPS panels for exterior insulation and interior works. Cracks are sealed with and expanded polystyrene is glued. The adhesive is moisture resistant. He is not afraid of mold. The composition is distinguished by high adhesion to concrete and other materials. A cylinder with a capacity of 750 mm is sufficient for 12 m of working surface.

Macroflex

Macroflex foam glue is produced in cylinders. There are two types of glue: for summer and for winter. The downside is the large expansion. In expansion, Macroflex 65 is able to double. Other brands of this adhesive expand less at low temperatures.

When choosing an adhesive foam, you need to take into account environmental conditions and types of finishing materials.

Subtleties of application

When working with foam glue, you must adhere to the following algorithm:

- Before work, read the instructions for use of the composition. It is particularly important to observe the air temperature indicated on the packaging.

- The cap is removed from the cylinder. The cylinder is installed in the gun.

- Shake the installed container well.

- First, the perimeter of the PVC board is covered with foam glue.This is done with an edge indent of 20 cm, then the adhesive is distributed diagonally.

- The object with the adhesive applied is pressed against the work surface and held for 5 minutes.

- After this period, check the regularity of the pose. If necessary, the masonry is corrected.

The resulting gaps can be filled with glue. This increases consumption.

Tips & Tricks

Experienced craftsmen share tips for buying and using foam glue:

- The glue should not be liquid. You can check the consistency at the time of purchase. There are testers in stores. Just squeeze a little glue to assess its consistency.

- When buying foam glue, you should look at the packaging for the density of its composition. The higher this indicator, the higher the consumption of adhesive will be.

- The label indicates whether it is possible to work the glue cold. The lower the number, the better. The fact is that formulations with a low temperature regime tolerate high temperatures just as well.

- When buying foam glue, be sure to familiarize yourself with the contents of the container. It should not contain carbon dioxide and freons. A good indicator is the presence of isocyanate oligomers.

- The initial setting time is indicated on the packaging. The optimal pace is 10-15 minutes.

- Assess the degree of adhesion. The minimum indicator for concrete is 0.3 MPa, for expanded polystyrene - 0.8 MPa.

There are many tools for joining PVC panels to concrete and other surfaces. Adhesive foam specially recommended for this purpose is the best solution.