Instructions for using glue for the b7000 phone screen, which can be replaced

The screens of devices with touch controls are slightly different from conventional screens. The main distinguishing feature is the presence of a touch screen, using which the electronic device is controlled.

When repairing such equipment, use special glue for the phone screen.

Content

- 1 Advantages and disadvantages of using

- 2 Types and how to use

- 3 Comparison of adhesives

- 4 Algorithm for replacing the phone screen with glue

- 5 How long does the glue dry

- 6 Other fields of application

- 7 Toxicity and harmfulness of components

- 8 Security engineering

- 9 How to remove glue from skin?

- 10 Glue Substitutes

- 11 Conclusion

Advantages and disadvantages of using

Before using an adhesive for phone screens, you should familiarize yourself with their main advantages and disadvantages. These funds have a number of advantages, including:

- Reliability. The main advantage of these adhesives is their reliability. They can be used to glue ordinary glass and plexiglass, which are often used in smartphones.

- Stealthy. Another important advantage of screen glue is invisibility. The composition is completely transparent, therefore, even after drying, the adhesive seams will be invisible.

- Moisture resistance. The components that make up the glue make it resistant to high levels of humidity.

- Resistance to mechanical damage. The screen adhesive is quite dense so it can withstand even severe impacts without issue.

- Heat resistance. Many types of phone screen adhesives have operating temperatures ranging from -60 to +155 degrees.

The main disadvantage of these adhesives is that they cannot protect the screen from drops.

Types and how to use

For gluing screens, different types of adhesives are used, the characteristics of which should be familiarized with before using them.

B-7000

This is a Chinese airtight adhesive made from epoxy resin. It is considered by many to be a versatile product as it can be used to bond glass, wood, iron and plastic. The composition is sold in small tubes, the volume of which can be from 50 to 150 milliliters.

At the ends of the tubes, special nozzles are installed through which the glue mixture is squeezed out. B-7000 can only be applied on a perfectly dry surface.

E-7000 and T-7000

E-7000 glue is most often used for working with jewelry, but some people use it for gluing glasses. This adhesive is sold in 50 ml tubes. An epoxy-based product is made, which makes it more reliable.

Some people use T-7000 as a replacement for B-7000 composition. However, experts do not recommend using it when gluing phone glasses, since the mixture is painted in a dark color.

T-8000, E-8000 and B-8000

The T-8000 is often used in everyday life to work with glass and plastic products.The main advantage of this glue is its reliability and ease of removal from the surface.

People who prefer to use viscous adhesives should be careful with E-8000. The composition is suitable not only for bonding glass, but also for bonding ceramics and fiberglass.

B-8000 is often used to seal mobile screens. It does not contain any toxic components and therefore does not corrode the surface.

E-6000 and B-6000

For gluing glasses, the composition E-6000 is often used. It is also capable of bonding plastic, stone, wood and fabric products. This glue sets in seconds and should therefore be used with great care.

When working with jewelry and smartphone screens, you can use the B-6000. It contains silicone, which makes the mixture more viscous and reliable.

B-5000

Previously, this glue solution was popular with people who were in the business of gluing smartphone bezels. Today the B-5000 is not produced, since it has been replaced by higher quality means.

Comparison of adhesives

Many people cannot choose the glue to glue the screen to the case. To determine which adhesive is better to use, it is necessary to compare their characteristics in advance.

Experts advise against using outdated formulations such as B-6000 and E-6000. They have low bond strength and poor resistance to high humidity. It is better to use modern compositions B-7000, T-7000 or E-7000.

Algorithm for replacing the phone screen with glue

Before you start working, you should familiarize yourself with the functionality of replacing smartphone screens. This procedure takes place in several sequential steps:

- Disassembling the smartphone.First you need to disassemble the phone and remove the battery from it. Difficulties may arise when disassembling modern phones, since they have a non-removable shell. In this case, you will need to carefully remove it with a plastic card. Then the housing elements with cables and boards are removed.

- Removing the shield module. To remove the touchscreen, you will need to carefully warm the device with a hair dryer for 2-3 minutes. After that, a suction cup is connected to the module, which is carefully pulled towards itself in order to carefully remove the screen.

- Disconnecting the array from the sensor. When replacing touch screens, be sure to disconnect the matrix. To do this, it is heated with a hair dryer to 75-85 degrees, after which a nylon thread is wound under one of the edges. You need to wind the wire very carefully so that it passes through the adhesive layer.

- Matrix cleaning. After detachment, the matrix is cleaned of the remains of dried glue. When cleaning, use wipes soaked in an alcohol solution.

- Application of glue. A sealant is applied to the surface of the cleaned matrix. In addition, it is evenly distributed over the entire surface.

- Installing the module. Before placing the display module, the seat is cleaned. After cleaning, the perimeter of the case is treated with glue, on which the touch screen is installed.

- Assembling and testing a smartphone. The assembled phone needs to be checked.

How long does the glue dry

People who are going to use adhesive solutions for screens are interested in the drying time. Several factors determine the drying time:

- Temperature indicators. The drying speed of adhesives is directly dependent on the temperature.To dry them faster, it is necessary to maintain the ambient temperature in the room, which will not fall below 20 degrees. At low temperatures, the glue dries for a long time.

- Humidity level. Another common factor that affects drying time is air humidity. In order for the glue to dry normally, the humidity in the room should not exceed 60-65%.

Other fields of application

Some people think that display glue is only used for gluing screens, but it is not. There are other fields in which such adhesives are used.

Linking Jewelry

Many crafters use B-7000 superglue, which dries quickly after being applied to the surface. Most often it is used for gluing plastic jewelry. To properly hold the products together, you will need to apply glue in several layers. One layer will not be enough, since such a seam can disperse with temperature changes.

working with real leather

Super glues are often used to work with genuine leather products. Most often it is used to create leather wallets, belts, hairpins and jewelry. When gluing the skin, use the compositions E-7000 and T-7000.

Before applying the glue, the surface of the leather is cleaned with sandpaper and degreased to strengthen the glue joint.

Bonding plastic and decorative clay

Many ornaments are made from decorative clay and plastic. When gluing plastic and clay products, T-8000 and B-8000 adhesives are used. Before gluing, the surfaces are moistened with acetone to degrease them.

Toxicity and harmfulness of components

Many people think that screen adhesives are completely safe, but they are not.They contain epoxy resin, which consists of toluene. At temperatures of 50-60 degrees, this component negatively affects the functioning of the liver and nervous system. In addition, when it comes into contact with the surface of the skin, the epoxy causes eczema or dermatitis.

Security engineering

When working with adhesives, be sure to observe the following safety rules:

- Clothing protection. Experts advise against working with glue in everyday clothes, as it is difficult to wash off.

- Hand protection. It's no secret that adhesive mixtures cause skin diseases and therefore protective gloves should be used.

- Room ventilation. Adhesives release vapors into the air that are hazardous to human health. To remove fumes, when working with glue, periodically ventilate the room.

How to remove glue from skin?

People who regularly work with glue are often faced with the need to clean their skin. There are two effective remedies that will quickly remove the substance from the surface of the skin.

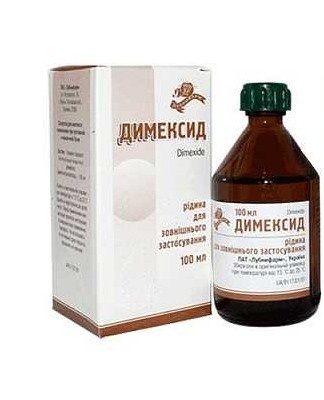

"Dimexide"

Often, when dissolving superglue, they use "Dimexidum", which is sold in any pharmacy. Before cleaning, the product is diluted with water in a ratio of one to three. To get rid of dried glue stains, you need to moisten them with a solution and wipe them with a napkin after 2-3 minutes.

Acetone with soap to remove

Acetone is considered the most common skin glue remover. A small piece of fabric is moistened with acetone, after which the dried layer of glue is wiped off. Then the treated skin area is washed thoroughly with warm water and soap.

Glue Substitutes

Some people do not want to use glue when attaching the smartphone screen. In this case, you will have to use substitutes for adhesive solutions. Most often, instead of adhesives, double-sided tape is used, which securely attaches the display modules to the case. The advantages of scotch tape are its low cost and ease of use.

In addition, to install the screen, use special fixing OCA films. Their main and only drawback is that the film is selected individually for each smartphone model.

Conclusion

When repairing and replacing screens on mobile devices, superglue is used. Before using it, you need to understand the types of adhesives, their characteristics and nuances of use.