Types of Conductive Adhesives for Rear Window Heater DIY Repair and How to Use

The heated rear window is made of small-diameter metal wires. Therefore, they often break and break. It will be possible to eliminate such damage on your own, without resorting to professional craftsmen. To eliminate the breakdown, it is important to choose the right product. Using a special conductive adhesive for repairing the heated rear window gives excellent results.

What is the rear window heating system

The rear window of the car is heated thanks to special threads. This process takes place under the influence of a direct current flowing through them. The wires are made of a conductive substance which has little resistance.

The total current for the rear window defroster is 10 amps. The system uses about 10 threads. This means that a current of approximately 1 Ampere passes through each element.According to Ohm's law, the resistance of the filament can be calculated at approximately 12 ohms. In the factory production of rear windows, heating wires are applied in different ways. This can be done with the following methods:

- vacuum spraying - is considered the most reliable method;

- electrochemical;

- bonding.

Filaments can include a wide variety of elements and alloys. These include chromium, nickel, tungsten. Also, the wires may contain resins, graphite, copper. Depending on the type of these threads, the appropriate repair method should be selected.

Thus, it is forbidden to use solder for wires that have been obtained by vacuum deposition with a carbonaceous substance. In such a situation, it is permissible to use only conductive adhesive.

Malfunction symptoms

The rear window heating filaments break after the end of the vehicle's extended life. Mechanical damage also leads to their breakdown. As a result, the driver is confronted with a lack of heating of the glass fragment. This causes the appearance of condensation with significant temperature variations inside the passenger compartment and on the street. This usually happens during the winter season.

It should be remembered that fogged glass significantly reduces visibility on the road. As a result, the risk of road accidents increases. It is quite possible to solve the problem with your own hands. To do this, you need to use a special glue or paste. In order to identify a malfunction in a timely manner, it is worth paying attention to certain signs.

Slow fog of the glass

The appearance of a defect in the structure of the yarns is evidenced by the delayed bleeding of the glass.

Horizontal stripes on glass

If the heating system is damaged, the glass is covered with horizontal misting strips. There is also a risk of icing.

No heating

In the event of a fault, the heated rear screen may disappear completely.

Location of damage

Available methods can be used to identify problems in a timely manner.

Visually

The reasons for the failure can be identified visually. A bad fuse will indicate an inoperative rear window defogger indicator when the button is pressed. If the light is on and the heating wires do not work, you can suspect faults in the relay. The loss of contacts in the system causes delayed sweating.

If the inspection of the rear window did not identify a break in the heating line, it is worth starting complex procedures.

At first, it is recommended to simply turn on the heating. In the area without heating, you can see a characteristic band.

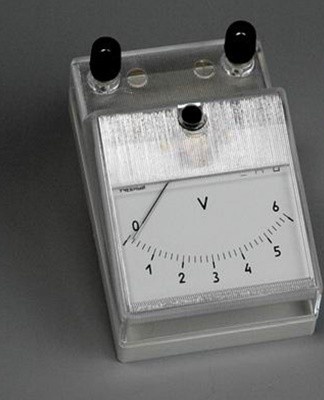

Voltmeter

To use this method, you need to take a voltmeter and turn on the rear seat heating. In this case, it is recommended to place one probe on the weight of the machine and wrap the other in aluminum foil. After that, it's worth moving slowly along each line until the middle is reached. The standard voltage should be 5 volts. At a lower value, the cliff area can be said to have been found. An increase in value to 12 volts also means an open circuit.

There is also another method of using a voltmeter. To do this, it is recommended to connect the plus to the terminal to a specific heating contact. The second probe should be moved smoothly along the line. This should be done on the negative terminal side. A drop in voltage indicates a rupture zone.

Ohmmeter

Experts advise using an ordinary device with arrows. When powering on the device, it is recommended to select mega mode. The sensors must be connected to the rear window heating terminal. As a connecting element, ordinary cotton is used. It is moistened in distilled water. After that, it is recommended to follow the line and evaluate the reaction of the arrow. It is she who will show the cliff area.

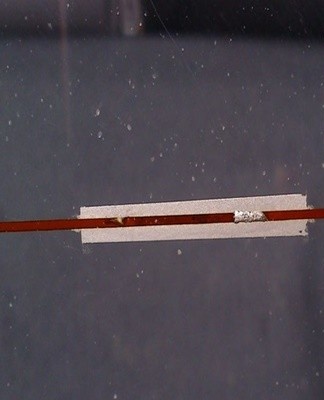

How to Determine Where a Conductive Tape Breaks

To identify the cliff area, it is worth using a multimeter - digital or a pointer. It is recommended that you perform the diagnostics in the following order:

- Turn on the heating.

- Configure the multimeter to measure voltage.

- Connect the negative probe of the device to the ground of the car.

- Move the positive probe. It is recommended to do this along a horizontal conductor. This will help identify the open circuit contact area of the electrical circuit.

It is not difficult to identify the damaged area of the metal tape. When measuring a horizontal conductor in the presence of resistance on the trace, the voltage will drop significantly. This value can even reach 0. If this is not respected, it is possible to judge a break in this conductor. The exact section can be determined by a sudden voltage jump of 12 parameters or less to 0 volts.

If you want to find the driver's area of damage on the glass removed from the car or in the absence of a connected battery, the diagnosis is carried out using an ohmmeter.

It is also permitted to use a digital multimeter. It is recommended to set it to resistance measurement mode. To identify the area of the gap, the negative probe of the device must be connected to a fragment of the negative bus.In this case, the positive must be carefully driven along the conductive part of the horizontal strip. This is done before a sudden jump in the device settings.

How to fix with glue

Repair of the terminals can be carried out by soldering or using a special adhesive. In the second case, it is recommended to choose a conductive substance.

To perform the procedure, you need to perform the following steps:

- Clean the glass from dust in the damaged conductor area. After that, it is recommended to degrease it. For this purpose, acetone should be used.

- Tape several layers of electrical tape along the damaged tape on each side. It is also allowed to use tape.

- Process the resulting stencil with glue. This is done so that its layer extends at least 10 millimeters over the intact conductor. Moreover, it should be done from all sides.

The amount of adhesive depends on the dimensions of the heating rails. To obtain a high-quality coating, it is worth applying at least 2 layers of a conductive substance.

Choosing an Appropriate Compound for Wire Restoration

To successfully choose an adhesive, it is necessary to pay attention to the properties of each of the compositions. Several popular options can be found on sale today.

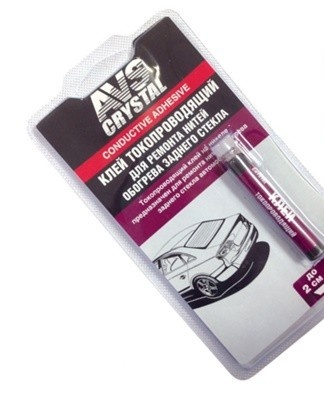

AVS A78358S

It is a conductive adhesive that is often used to repair broken rear window heater filaments. A container with a volume of 2 milliliters will cost about 200 rubles.

Contact

This substance is highly conductive.

ASTPOhim

This conductive substance is intended to repair broken wires. It is allowed to use it if the damage does not exceed 2 centimeters.

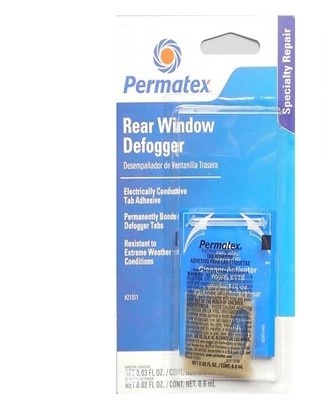

Permatex 21351

This conductive agent is suitable for thread repair.It can be purchased for 400 rubles.

How to do it yourself

To repair the heating wires, it is not at all necessary to use special substances. Conductive glue is quite acceptable to do with your own hands. There are several popular options for these products.

Superglue with aluminum shavings

To obtain an effective conductive composition, it is worth moving chips and superglue. These substances are taken in equal proportions.

Silver Graphite Powder Nail Polish

It is recommended to add 2 kinds of powder to the bottle with varnish. To mix the composition, you need to use a toothpick.

Epoxy resin and copper shavings

For the manufacture of glue, it is recommended to mix epoxy resin with shavings. In this case, the ratio of 5: 1 should be observed. It is recommended to add the amine ingredient before application. The resin needs to harden.

Tsaponlak and graphite powder

To obtain graphite powder, it is recommended to grind the core of the battery. Powder can also be obtained from a graphite pencil. To prepare the adhesive, it is recommended to mix tsaponlak with graphite powder in a 2: 1 ratio.

Additional tips and tricks

Today, many effective compositions are known with which you can repair heating wires. It is allowed to use glue BF-2 or BF-6 as a base. It is also allowed to use other substances that dry quickly. Often paint, enamel, polymer resin are used for this purpose. To make a conductive paste from the listed materials, it is worth adding small shavings to it. This substance can be obtained from a small file.You can also use brass, aluminum or copper.

After combining the ingredients, it is recommended to apply them to the prepared surface. To do this, you need to use a homemade stencil. This can easily be done with electrical tape. It is also permissible to use construction tape for this purpose. In terms of effectiveness, homemade glue is not inferior to ready-made compositions. It is also permissible to solder the area of damaged wire or terminal disconnection. This procedure cannot be performed if the distance between the thread fragments exceeds 2 millimeters. First, the electrochemical method is used.

Soldering is considered a more efficient and reliable method of eliminating contact breaks. It is made using a standard method, which involves the use of flux and solder. The stream must be FCA type. It must be based on zinc chloride. POS-18 or similar is used as a solder.

Electroplating is considered an effective repair method. For this procedure, you will need a liquid based on copper sulfate. It is recommended to add 2 teaspoons of copper sulphate to 100 milliliters of water. It is also allowed to introduce battery electrolyte into the composition - only a few drops.

In addition, you will need to prepare a copper wire, the cross section of which is 6 square millimeters. A copper brush prototype is made from the wire. Next, the stripped conductor, wrapped in rags and wire, must be connected to a power source. This is done with the opposite end of the yarn. In this case, the minus of the battery is connected to the body. The brush should be moistened with an electrolyte solution and carefully agitated around the wire break. Gradually, the treatment area will be covered with copper particles.This is due to the electrolysis process.

It should be borne in mind that the resistance of such a coating is small for high current. Therefore, this section must be additionally soldered by means of copper wire. It is important to understand that this method is not used to fix large gaps.

Steel shavings and glue can be used for repairs. To do this, you need to clean the surface. Then place the magnet behind the glass. This will help form a mountain of sawdust. It is worth applying BF-2 glue on it. After drying, a layer of fixing glue is used. The use of adhesives to repair rear window breakage can achieve an excellent effect. At the same time, it is important to choose the right substance and observe the technology of its application.