Description of the types of wallpaper glue, which one to choose and how to raise

The quality of the work performed directly depends on the correctly selected wallpaper glue. When choosing the right type of adhesive, consider the type of wallpaper, substrate and environment. It is also recommended to familiarize yourself with the products demanded in the construction market by well-known manufacturers.

Content

- 1 Types and characteristics of wallpaper

- 2 Types of glues by type of support

- 3 Characteristics of a good adhesive

- 4 Recommendations of choice according to the type of wallpaper

- 5 How to breed correctly

- 6 How to estimate consumption

- 7 How much is stored diluted

- 8 Manufacturers and their characteristics

- 9 Home manufacturing technology

- 10 Tips & Tricks

Types and characteristics of wallpaper

Glue is used for different types of wallpapers, which differ in material and physical properties. When planning a renovation, it's worth exploring the features of all wallpaper options.

Paper

Paper wallpaper is the most common type of product due to its low cost.In addition to affordability, the following positive features can be distinguished:

- High respect for the environment. Since paper is a product of wood processing, there are no third-party impurities and harmful substances in the composition. Paper wallpapers are produced by special processing of wood and rolling the material in a press to obtain strips of the desired size.

- Ease of use. Gluing technology involves applying glue to the entire surface and subsequent fixing on the wall. To tear the wallpaper, simply soak the material and scrape with a spatula. In most cases, the coating simply peels off the dry wall.

- Porous structure. Paper is able to pass moisture particles through its pores, which prevents the development of fungal microorganisms and mold.

In addition to a number of advantages, the paper material has several disadvantages. The coating cannot be used in rooms with high humidity due to the risk of detachment from the wall. In addition, the material cannot be washed and will lose its original appearance over time. Over time, wallpaper fades and fades when exposed to sunlight and other environmental factors.

Vinyl

Vinyl wallpaper is a two-layer material. The bottom layer is non-woven or paper, and the top layer is polyvinyl chloride, on which patterns and embossing are applied. In some varieties there is an additional intermediate layer to help hide defects on the wall. If the walls are finished without preliminary leveling with plaster, chipboard or plywood, then the foam version of the wallpaper is suitable for hiding irregularities. The popularity of vinyl is due to the following advantages:

- resistance to chemical components that are included in the composition of household detergents;

- the possibility of using in rooms with variable humidity;

- strength and dense structure.

The disadvantage of vinyl flooring is that it does not allow air to pass through. For this reason, it is not recommended to stick on children's rooms, bedrooms and other rooms where there are difficulties in air exchange.

Textile

Textile-based wallpaper is produced in ready-made rolls of standard sizes or in rolls for seamless gluing. These rolls have a width of 3 m and a length of up to 50 m. The image on the material is located across, and the gluing process is carried out in the same way. This technology makes it possible to create a solid coating on the walls.

Textile wallpapers are superior to other varieties in terms of decorative characteristics. A room covered with such material will look original and stylish. In addition, the coating provides thermal and sound insulation. Additional benefits include environmental friendliness and long service life.

Since textiles are sensitive to odors, it is necessary to ventilate the room regularly so that the wallpaper does not absorb unwanted odors. Since the material can accumulate dust and be damaged by frequent wet cleaning, dry cleaning is recommended to clean the textile backing.

Before gluing wallpaper to a textile backing, you must first prepare the walls. The old coating is torn off the surface, all uneven parts are primed and puttied. For gluing it is necessary to use only a specialized type of adhesive solution.

Fiberglass

At the heart of fiberglass is an environmentally friendly substance characterized by wear resistance and affordable cost.Fiberglass wallpaper is often used for interior decoration, including walls and ceilings. The material is absolutely safe for humans and does not emit harmful toxins.

Fiberglass does not accumulate static stresses and does not absorb moisture, which prevents the development of fungi on bonded surfaces. Due to the structure of the coating, a layer of dust forms very slowly. For a long time, the fiberglass material does not wear out or deform, even when applied to the surface of detergents.

Fiberglass wallpaper can decorate any type of room. The variability of patterns on the material allows you to harmoniously complement various interiors. It is important to take into account that due to the complexity of production, the cost of production increases. Also, bonding to surfaces is a more complicated process than other varieties.

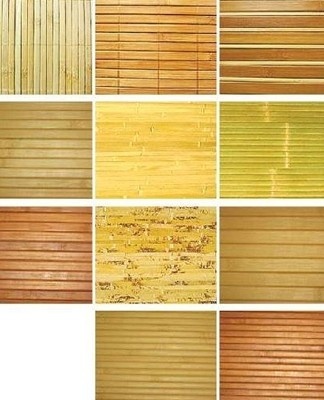

Bamboo

The use of materials of natural origin and plant themes is widespread in modern design solutions. Bamboo wallpapers have gained popularity precisely because of their decorative characteristics. The material adds sophistication to any interior, making it more attractive.

For the production of this type of coating, narrow strips of bamboo are used, which overlap the surface of the rice paper. The material without consequences is influenced by high and low temperatures, as well as variable humidity.

Most often, bamboo panels are used in the renovation of living quarters. Light colored wallpapers are used for finishing the ceilings, and darker ones for the walls. Natural ornament and color variability allow you to choose the ideal option for any consumer.

Types of glues by type of support

Depending on the type of substrate on which the wallpaper is applied, the appropriate type of glue is selected. Using the correct adhesive for the backing will ensure the wallpaper adheres firmly and evenly. The difference between all types of glue is in the composition, consistency and method of application.

Paper

The most common option for wall decoration is to cover the wallpaper with PVA glue. The substance is produced as a white mixture. Before use, you just need to dilute the mixture to the required consistency according to the attached instructions. Apply paper glue to the back of the material. In case of contact with the front part of the fabric, wipe it with a slightly damp sponge.

Nonwoven

When buying non-woven glue, it is important to correctly calculate the consumption of the substance in order to avoid unnecessary costs. This glue can be used for paper and two-layer non-woven coatings, but in the first case the consumption will be 2 times higher. To decorate a standard room, you will need to dilute about 200 g of substance in 5 liters of liquid.

Non-woven glue differs from paper glue in an improved quality indicator, since starch ether is used as a raw material for its production. The component improves the consistency of the mixture, adds viscosity, affects flow properties and moisture retention. The amount of starch added to the adhesive is manufacturer specific and adjusted to achieve the optimum structural viscosity. Starch esters in the composition are completely compatible with other substances, since they are chemically inert.

Universal

It is advisable to acquire a universal type of glue when decorating a room with several types of coatings. The product is suitable for rolls of all sizes and densities.Firm fixation on the walls is achieved due to the addition of synthetic resins and various chemical impurities to the composition. The ability to use any material is the main advantage of the all-purpose adhesive. The disadvantages of this substance include:

- higher cost compared to glue for a certain type of base;

- the presence of harmful components in the composition.

Specialized

A specialized type of glue is a dispersion solution with increased characteristics. It is often used for fiberglass and fabric wallpapers. The glue has a strong adhesion, therefore, if it is necessary to disassemble the coating, it will be necessary to use solvents.

In addition, specialized glue with an indicator has become widespread in the construction market. With the help of coloring components, the solution acquires a pinkish tint, thanks to which you can easily control the uniformity of the application on the surface of the base or canvas. This dye does not stain or penetrate the front side of the wallpaper, as it is neutralized during drying.

Characteristics of a good adhesive

A high-quality adhesive solution affects the result of the work performed and the strength of fixing the wallpaper to the walls. Having decided on the required type of glue, you need to familiarize yourself with its detailed characteristics in order to choose good quality products. Most buyers simply give preference to glue, which is produced by eminent manufacturers, but it is better to use an integrated approach.

Respect the environment

The absence of harmful components in the composition of the product affects the safety for the environment and human health. If chemical impurities have been used for the production of glue, they can be harmful.Therefore, when working, you will need to wear a protective mask so as not to inhale corrosive substances. As a rule, most manufacturers who produce environmentally friendly solutions indicate on the packaging the corresponding marking in the form of a green icon.

Hygiene

The hygiene indicator is similar in many respects and is associated with the environmental friendliness of the product. The hygiene criterion is determined taking into account the composition of the glue, the absence of a pungent odor and human exposure. The substance with good hygiene is characterized by a mild, non-toxic smell.

pH indicator

The acid-base pH is needed to determine the likelihood of yellow stains, which is especially important when using wallpaper in light colors. To prevent the appearance of stains on the material, the substance must have a neutral acid value. It is recommended to choose an adhesive with a pH between 6 and 7, regardless of the type of surface to be treated.

Primary adhesion

The initial adhesion, which is determined by the adhesion strength, expresses the strength of the bond between the wallpaper and the substrate when the glue has not yet dried and formed a hard layer. At this stage of pasting the wallpaper, adjustments are made to evenly align the patterns and seams. The role of the primary adhesion is only to fix the wallpaper to the surface before the final adhesion occurs. The indicator depends only on the consistency and viscosity of the glue and is not related to the composition and type of raw materials used for production.

Final adhesion

The final adhesion of the substance determines the strength of the bonding of the wallpaper to the surface after the glue has completely dried.The indicator depends on the ability of the adhesive to interact with mineral materials, including cement, lime, chalk, gypsum, as well as paper and other types of substrates used in wallpapering. The final adhesion is influenced by the composition of the adhesive, the type of support and wallpaper.

Water resistance

Water resistance determines the ability of the adhesive not to soften when the atmosphere is excessively humid. Use a waterproof product to carry out repair and finishing work in the bathroom, kitchen and industrial premises.

Compatibility

The compatibility of glue with other materials allows you to mix different substances without mutual deterioration of characteristics. The compatibility index depends on the type of surface to be treated and the constituent components of the glue. When choosing a substance, you need to know exactly what surface the work will be done on in order to select the appropriate glue.

Sustainability

The duration of fixing the wallpaper on the surface depends on the indicator of long-term pasting. Modern adhesive solutions are able to hold the coating for many years, but in the case of using poor-quality raw materials, the wallpaper begins to peel off the walls.

Recommendations of choice according to the type of wallpaper

The type of wallpaper is one of the key criteria for choosing glue. In order for the material to adhere better to the wall and not show defects over time, you need to choose an adhesive designed for a specific type of coating.

Light paper

For gluing a light-weight type of wallpaper, a standard adhesive solution based on PVA or a vinyl mixture is suitable. The adhesive designed for lightweight wallpapers is applied once and then immediately applied to the surface.The slippery consistency of the substance allows you to easily align the pattern on the canvas and join the sheets.

Until the solution dries completely, it is even allowed to tear the canvas completely and glue it again without adding a new portion of glue.

Thick paper

The difference with gluing thick paper wallpapers is that they first cover the base with an adhesive mixture and wait for absorption. Then a second layer of solution is applied and wallpapering is done. They fix heavy canvases with vinyl glue or PVA.

Nonwoven

Standard paper glue is not suitable for non-woven wallpaper. In order to securely fix the non-woven wallpaper on the walls, a special version is required for this category. As a rule, an adhesive solution for nonwoven materials is produced in the form of a powder, which is diluted with a liquid before direct use.

Fiberglass

Coatings based on fiberglass are glued with a specialized glue.The best option is to purchase a composition from the same manufacturer as the wallpaper. Modern glass wallpaper manufacturers often offer the appropriate glue in the kit. If the substance is not included in the kit, you must choose one of the following options:

- A dry mix that is diluted with water before use. This variety stands out for its affordable price, good performance and wide distribution (you can find the mixture in almost any hardware store).

- Ready-to-use formulas. After purchasing the composition, it is not necessary to dilute it, since it is completely ready for use. It is not recommended to buy the cheapest option, as this will affect the quality, and due to the rapid consumption, the savings will not make sense.

- Freeze-resistant fiberglass adhesive.Compounds of this category are used for wall decoration in summer cottages, gazebos and other rooms where there is no heating in the cold season. Frost-resistant glue withstands temperature drops to -40 degrees.

How to breed correctly

To prepare the solution, you need to purchase a suitable type of glue, a container for mixing, clean water at room temperature, a device for stirring the solution (a construction mixer or an improvised tool). Armed with the necessary materials, you should carefully read the instructions that come with the glue. This will help to avoid common mistakes and mix the substance with water in equal proportions. The standard instruction requires the following steps:

- Pour the liquid into the container in the amount indicated on the package with glue. For correct measurement of the amount of water, it is recommended to use measuring cups.

- Stir the water to form a funnel and while stirring, slowly pour in the dry glue. If you first add the substance, then start stirring, then immediately after entering the liquid, large lumps will form, which will be difficult to bring to a uniform consistency.

- Having filled in a sufficient amount of substance, you need to continue to actively stir the mixture for 10 minutes to form the desired density, then leave the finished glue for half an hour. During this time, the substance will swell and acquire adhesive characteristics. For thick wallpapers, you can leave the mixture for 1 hour.

How to estimate consumption

On packages with wallpaper paste, most manufacturers indicate an approximate consumption per 1 m². In this case, in practice, there are often surpluses or, on the contrary, new packaging has to be purchased.In order to correctly calculate flow rates, a number of nuances should be taken into account, including:

- The coated surface quickly absorbs glue, and pre-treatment with a primer will reduce the cost of glue above the standard value indicated on the package by about 5-10 g per 1 m². Mr.

- When fully lining the walls, you must take into account the entire area when calculating. If you do not plan to finish the space behind the cabinets or implement various design solutions, then the whole area will not be covered with wallpaper, and consumption will be reduced. In this case, you need to subtract the unglued areas from the total area.

- The consumption of the substance varies depending on the type of wallpaper. In some cases, the glue is applied only to the wallpaper itself, while in other situations the wall is treated. Due to different absorption properties and drying speed, the amount consumed will vary. For best results, use the appropriate adhesive for each type of flooring.

Based on the above nuances, you can begin to calculate the consumption of the substance. To do this, first determine the area of two walls located perpendicularly in the room, then multiply the result by half.To calculate the area of the longest wall, multiply the height by the length, then use a similar formula to determine the area of the short wall. Next, calculate the total area.

To get the most accurate value, you can subtract the dimensions of window and door openings from the total area, but, without special skills, it is better to take into account the entire area and use the excess paper paint and glue to seal the seams and align the pattern in problem areas.

After determining the area of the walls, the required number of rolls of wallpaper is calculated. For example, if a paper covering is used, its standard width is 0.53 m, and the length of one roll is about 10.5 m. These indicators are multiplied, and then the total area of the room is divided by the resulting indicator .

Accordingly, the consumption of wallpaper glue is determined taking into account all the calculated data. Based on the consumption data indicated on the package, it can be concluded in advance whether the content is sufficient to cover the room.

When diluting the composition, it is important to observe the recommended proportions of dry matter and liquid so as not to deviate from the norm.

How much is stored diluted

Often, during finishing and repair work, situations arise when there is much more glue than was needed. For this reason, the question arises of how long it is permissible to store the prepared solution. When buying an adhesive composition in a dry state, it is important to always pay attention to the production date, which is indicated on the packaging. A substance that is approaching the end of its shelf life should not be purchased, as its characteristics and storage capacity are significantly impaired.

The diluted solution can stand for 7-10 days, subject to a number of conditions. Including, it is required:

- low ambient temperature, but not below 0 degrees;

- find the solution in a tightly closed or hermetically sealed container;

- the absence of foreign bodies inside the container with a mixture, including rollers and brushes.

Mix well before using wallpaper paste again. A new solution and especially products from other manufacturers with a different composition should not be added to the remaining mixture.

When stored at standard room temperature (between 18 and 24 degrees), diluted glue cannot be used for more than one week. It should be understood that the specific storage time directly depends on the manufacturer and the composition. In any case, it is not recommended to use a diluted solution more than a week ago. Also, use should be discarded if there is an unpleasant pungent odor.

You can notice the damage to the glue caused by the changed consistency - the water will peel off from the main composition, and the solution itself will thicken in the form of flakes or lumps. If after long-term storage the solution has become too liquid, then it is pointless to use it for work, since the wallpaper will not stick to the walls.

The best option is to dilute the composition for gluing the walls in the minimum required amount. In this case, it will always be possible to use a freshly prepared solution with high characteristics. If the glue is already diluted and it becomes necessary to postpone repair work for a short time, it is enough to cover the solution tightly with cling film and mix well before application. It is not necessary to remove the glue for several hours in a cool place. This recommendation is also relevant when leaving the solution for an overnight break.

Manufacturers and their characteristics

A large number of different types of glues are presented on the construction market, which differ in physical properties, method of dilution, cost and other characteristics. To purchase the best option, you need to familiarize yourself with the products of well-known manufacturers and choose the appropriate glue, taking into account individual requirements and preferences.

France

French manufacturers occupy one of the leading positions and offer high-quality adhesive solutions for processing various surfaces. Despite the high quality of the products, you can purchase materials for finishing work at an affordable cost.

bostik

The adhesive produced under the Bostik brand is available in several variants designed to work with a variety of wallpapers including non-woven, textiles, paper and vinyl. Bostik also develops specialized formulations for glass mats and glass panels. All products have the same high adhesion to various substrates. You can use the glue on concrete walls, drywall, cement plaster, old wallpaper or painted walls.

Bostik products contain dispersion, PVA and starch. The components are absolutely safe for human health and the environment, since they do not emit toxic substances into the atmosphere. The advantages of the adhesive solutions of this brand are also:

- ease of use - it is enough to dilute the composition with water and mix;

- a wide assortment to choose from, taking into account specific application goals;

- preservation of the property of elasticity after complete solidification;

- economical consumption and sustainability;

- chemical resistance.

Axton

Axton glue is suitable for all types of wallpaper.Also, the manufacturer produces a type of solution with a color indicator, which simplifies the repair and finishing process. The list of the main advantages of the products of this brand includes:

- the composition is easily diluted in liquid, does not form lumps;

- the products are pre-tested in the laboratory and in real conditions;

- after being applied to the wall and drying, the glue does not stain the wallpaper;

- the main component of the composition is environmentally friendly modified starch.

Quelyd

The Quelyd brand is widespread in the Russian building materials market. The French company, engaged in the production and sale of the product, has been developing and producing high-quality adhesive solutions for finishing of any complexity for more than a hundred years. The high demand from domestic consumers is explained by the presence of the following characteristics:

- Products include: starch, cellulosic impurities, bactericidal and fungicidal substances. Simple components are very effective, which makes the cost of formulations affordable.

- The prepared substance has a long shelf life, and the diluted glue can be used for its intended purpose within a few days without losing its original characteristics.

- The glue gradually hardens, which makes it possible to adjust the position of the wallpaper and align the seams.

- The Quelyd brand produces many formulations for common types of wallpaper. Depending on the needs, it will be possible to select the required option.

- Due to its good adhesive properties, moderate consumption of the substance occurs.

- The absence of toxic components guarantees safety for health and the environment.

Semin Sem Mural

Semin Sem Murale glues are available ready to use.Solutions with high adhesion characteristics are recommended by many manufacturers of heavy wallpapers, textiles and fiberglass materials. The elastic consistency allows precise fitting of joints and prevents delamination.

According to its external characteristics, the finished solution is a homogeneous white, gelatinous mass without lumps, with a low viscosity index. The substance glides well, does not spread on the surface and does not run on application. After complete drying, the adhesive layer becomes transparent, durable and resistant to liquids. Over time, the glue does not turn yellow, does not leave stains on the wallpaper, does not undergo the development of mold. The formulations of Semin Sem Murale are suitable for use in damp areas.

Cleo

Kleo wallpaper paste from the famous French brand Ascott Deco is available in several versions. The manufacturer produces compositions for processing nonwovens, paper, velor, textiles, bamboo and other types of wallpaper. There is also a specialized Kleo Kids solution for use in children's bedrooms. For beginners, a composition with a colored indicator is offered.

Kleo Ultra is suitable for fiberglass and washable surfaces.

Kleo products consist of two components - an antifungal additive and modified starch. The components are absolutely safe and easily dissolve in liquid. The finished composition has good sliding properties, which allows you to easily adjust the position of the wallpaper and align the seams. After drying, the solution becomes transparent and does not leave yellowness on the surface of the material. The neutral acid-base index contributes to the anti-allergenicity of the glue.

Germany

A number of German manufacturers are engaged in the development and production of adhesives. In the building materials industry, there are several brands that offer a wide variety of products. When choosing wallpaper glue produced by German companies, you should familiarize yourself with popular brands that are common in the Russian market.

"Moment" (Henkel)

Glue "Moment" from the famous company Henkel is an instant substance created on the basis of modified starch. The high quality product has the following features:

- elastic structure for the possibility of adjusting the joints;

- economical consumption;

- the ability to easily wipe off the remnants of the solution from the surface of the canvas;

- the shelf life of the diluted solution is 10 days.

You can use Moment products for different types of wallpaper. The range includes universal and specialized substances.

Ekon

The Ekon line of wallpaper adhesives is actively spreading among domestic consumers. The following varieties are produced under this brand:

- universal, designed to glue any wallpaper;

- vinyl, to work with the corresponding type of canvas;

- extra strong, used to bond heavy materials with a non-woven backing.

The product contains impurities of starch and methylcellulose, which improve the strength characteristics. Properly diluted solution ensures reliable adhesion to the surface.

Methylane

German glue "Methylane" became the first product in the world with a color indicator, which became the reason for its wide distribution. The company offers various substances for working with paper, vinyl, textile, duplex and other canvases. There is also a universal option that combines the features of specialty products.Methylene solutions differ from alternatives in clearly calculated consumption, which is indicated on the package.

Knauf

Knauf brand products are designed to work with heavy types of wallpaper, which are attached to concrete, brick and plaster surfaces. The adhesive is suitable for cladding walls with an uneven surface, as its consistency allows it to hide defects and fill existing cracks. Solutions are used for interior finishing works.

Russia

Russian and foreign manufacturers are actively developing and presenting high-quality adhesive solutions on the market. Recently, many domestic companies have gained popularity among buyers.

"Oscar"

Universal acrylic glue "Oscar" is designed to work with fiberglass and fiberglass wallpaper, intended for painting. The substance quickly and reliably adheres to heavy types of coatings on any non-absorbent surface, including including plastic and concrete. The glue is produced in Russia using patented European technology. The main advantages are high adhesive properties and the presence of antiseptic additives in the composition to prevent the formation of mold.

Deco

Decoro glue is used for fixing thick wallpapers. The composition contains PVA, which improves the adhesion capacity and retention of the material, regardless of its density. Methylcellulose is also included, thanks to which the sliding of the canvas on the wall at the time of laying is achieved. To prepare the solution, simply dilute the dry mixture in water and stir for 5 minutes. The finished solution can be stored for a month.

Quality

Quality products are valued for their environmental friendliness and human safety.All compositions offered on the construction market are certified. Starch is used as a basic component for the production of adhesive solutions.

Glue preparation time takes about 10-15 minutes. Detailed instructions for use are indicated on the packaging. Depending on the consistency of the substance, it can be used for working with different types of wallpaper, as well as for priming the base.

"Lakra"

Lakra waterproof glue is made on the basis of aqueous dispersion of PVA. The substance has a high bond strength and an optimal drying time. Lakra glue forms an elastic and completely transparent film. The solution can be used to fix various types of wallpaper, including fiberglass, textile, non-woven, paper and others.

Titan

Titan glue can be used for interior and exterior decoration. The solution is economically consumed and reliably fixes any type of wallpaper on the walls. Since the substance is colorless, there is no risk of yellow stains on the canvas after drying. For surface treatment it is not necessary to prepare a solution - it is sold ready for use.

Britain

Products from British manufacturers are less common among domestic buyers, but are not inferior in quality to German and French counterparts. An affordable price policy allows you to carry out finishing work at a lower cost.

Exclusive

Exclusive glue contains modified starch, methylcellulose and antiseptic components. The adhesive is suitable for heavy vinyl, smooth paintable non-woven wallpapers and other types of non-woven backed canvas. To prepare the solution, it is enough to dilute the dry mixture with water and stir until a homogeneous mass is formed.

Ukraine

The presence of Ukrainian manufacturers did not bypass the domestic market. Manufactured products have a decent level of quality and are actively distributed in many hardware stores.

"Amyl"

The most popular Ukrainian brand of wallpaper paste in Russia is the Amil brand. The substance is suitable for gluing non-woven, vinyl and textile wallpapers. The solution is one of the instant adhesives, and to use it, just pour the dry mixture into warm water and stir well for 5-10 minutes.

Italy

Italian manufacturers offer a small variety of adhesive solutions, which allows you to focus on the quality of the product.

In addition to their high quality, the formulations are widespread due to their good adhesive characteristics, safety for humans and the environment.

AFM

The ACM brand is a popular Italian manufacturer of adhesive solutions designed to work with different types of wallpaper. The company produces specialized and universal formulations that are valued for their increased environmental friendliness and resistance to negative external influences during operation.

Home manufacturing technology

At home you can cook glue made from 60 g of flour and 1 liter of water. It needs:

- pour water into a saucepan, put it on the stove and wait until it boils;

- in another container, mix the flour and cold water to form a thick consistency;

- add a pinch of starch and boiled water to the resulting composition, stirring constantly;

- re-boil the resulting mixture and use after cooling.

The quality of glue prepared by yourself will differ in quality and adhesion from professional formulations. After preparing the substance, check the adhesion strength on small pieces of wallpaper.You can use homemade glue on any surface.

Tips & Tricks

When choosing and buying glue for finishing work, there are a few tips to keep in mind to avoid basic mistakes. The most reliable solution is carboxymethylcellulose, but it is suitable only for plaster surfaces.

It is best to cover the painted walls with a glue based on methylcellulose with the addition of polyvinyl acetate. If you plan to use thick paper or textile wallpaper, the amount of polyvinyl acetate should exceed 50%.

For light wallpaper, it is worth choosing a solution with an acid number of at least 8. Otherwise, the finished solution may leave yellow spots on the surface of the material. High-quality glue dries for 18-20 seconds and becomes transparent, after which it takes time to dry completely. When carrying out repairs in rooms with high humidity, it is recommended to use substances containing special antiseptic additives that protect against the development of mold.