How and what to use for gluing polystyrene to metal, a review of popular brands

Polyfoam has recently been used for thermal insulation of buildings. The use of this material significantly saves financial resources and time for finishing work. It adheres easily to plastic, wood, foam, concrete. It will take some effort to attach it to the gland. Let's see how to properly glue the foam to the metal.

What is necessary

Prepare in advance:

- measuring device (tape measure), knife, spatulas;

- rubber gloves (a rag can be used), burlap or clean rags;

- degreaser;

- a grinder (for cleaning a metal surface);

- adhesive composition;

- a wooden backing or a sheet of plywood for a foam board.

When using glue or spray foam, you should also stock up on rinse aid.

Which glue is right

The composition for fixing should not include acetone, gasoline and other solvents. They cause the destruction of polystyrene foam sheets.

Polyurethane foam

Benefits include:

- ease of use: a master who does not have installation skills can work with foam;

- low cost of composition;

- the foam is sold in cylinders, so it is used not only for gluing the foam, but also for sealing the joints of the plates.

Disadvantages: the tool glues all materials, but does not tolerate slowness. The foam dries quickly in the tube, so a special solvent will be needed.

Polyurethane

Benefits :

- synthetic glue is easy to apply;

- it is more resistant to humidity than dry mixes;

- frost resistant;

- guarantees high adhesion;

- moderate consumption of the composition (1 cylinder is enough for 10 m2).

The only downside is that an assembly gun is required to operate the spray glue.

Liquid Nails

They are not considered a reliable tool. Therefore, for strong fixation, they are used with a dry adhesive mixture. Application proportions on the surface:

- 1/3 - liquid nails;

- 2/3 - dry mix.

This ratio ensures high adhesive strength. In this case, the panel supports are not necessary.

Surface preparation

Preparation of the adhesive surface includes:

- cleaning of dyes, rust, dust;

- degreasing.

Suitable for removing greasy substances from metal surfaces: detergent, kerosene, white spirit, petrol.

Work execution

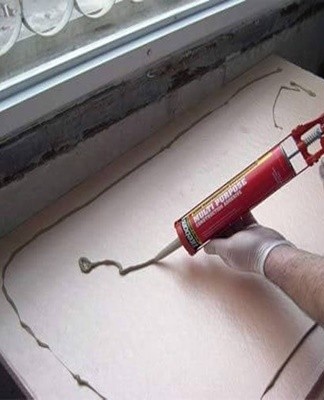

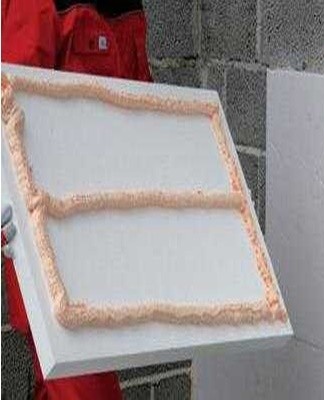

After carrying out the preparatory work on the plate, according to the instructions, distribute the adhesive composition (at least 5 points of contact). The sheet is firmly pressed against the area to be bonded.

Additionally, if a dry mix was used, the foam is supported by a wooden board or plywood until the glue is dry. This will help prevent the slabs from shifting.

Review of popular brands

The adhesive used for bonding expanded polystyrene sheets to metal must be characterized by:

- endurance at lower temperatures;

- the ability to use for outdoor work;

- the absence of any solvent in the product;

- guaranteed high degree of adhesion of glued surfaces;

- ease of use.

It is better to choose a composition that contains composite mixtures, bitumen or plasticizers.

"Ceresit"

Due to the high quality, the brand's products are respected by professional manufacturers. Advantages of Ceresit glue:

- ideally applied to foam blocks;

- good plasticity;

- can be used for indoor and outdoor work, resistant to temperature extremes and various atmospheric phenomena;

- shock-resistant and vapor-permeable composition;

- ecological;

- long period of correction (20-25 min.).

Disadvantage: The working solution must be used within 2 hours.

"Moment"

The range of Moment glues is growing every year. Positive properties of the composition:

- even with prolonged use, the glue joint does not crack;

- has excellent technical characteristics;

- does not shrink when drying, does not deform;

- frost resistance, water resistance, heat resistance;

- the adhesive is available in containers of different sizes;

- short hardening period.

The disadvantages include the unpleasant smell of glue (disappears only after complete drying), more often than others it is faked (as a result of which the presence of toxic and harmful components is observed in the composition).

"Master Termol"

Master Termol combined foam adhesive has the following properties:

- long-term for plate adjustment (up to 50 minutes);

- high adhesion and plasticity;

- the composition is environmentally friendly;

- the lowest temperature for the use of the mixture is -5 ˚С, which allows you to start installation work earlier and finish it later;

- the technological movement time is 12 hours, after which it is possible to dowel the foam.

The time of use of the finished composition is 30 minutes, the material consumption per 1 m2 is 6 kg.

"Proline 3K-45"

Adhesive mixture for laying foam and mineral wool, which is suitable for interior and exterior decoration. Positive properties of the composition:

- ease of use;

- moisture resistance, elasticity, frost resistance;

- frugality;

- high adhesion;

- shelf life of the finished mixture 2 hours;

- environmentally friendly product.

When preparing the composition, preventive safety measures should be observed. The dry mixture is characterized by increased dust formation, therefore it is necessary to protect the eyes and respiratory tract from it.

"Penoplex Fast Fix"

Highly effective compound for the installation of thermal insulation. Benefits of glue:

- universal - it also sticks foam plastic well on various surfaces, including metal;

- ease of use - the time for preparing the adhesive is reduced;

- heat resistance - not afraid of temperature differences from -50 to +90 ˚С;

- after the glue has hardened, the thermal conductivity is not disturbed;

- no shrinkage.

Those who used Penoplex Fastfix glue consider the disadvantages that the amount of work done on the surface coating does not correspond to that mentioned on the package, it is much less.

Feasibility of using foam

Using foam as an adhesive makes handling foam faster and easier. Its use is advisable if all actions need to be performed efficiently and quickly.The product is distinguished by low power consumption and excellent technical characteristics.

Benefits of using foam:

- ease of use;

- there is no need for technical breaks - working time is halved;

- no need to hammer the dowels, install a reinforcement layer;

- installation work can be carried out even in the cold season;

- has increased fire resistance.

Foam is more expensive than simple dry mixes, but justifies the cost. 1 cylinder is enough for 20-25 m2. To carry out installation work on gluing foam to metal, subject to certain rules, is within reach even for a beginner. Performing the connection on his own, a novice assistant will be able to save financial resources and be confident in the quality of the work performed.