Features of cold welding glue for linoleum, review of the best brands and instructions for use

Linoleum continues to be a popular floor covering for its versatility, affordability and ease of installation. In order for this material to serve for a long time and reliably, it is important to correctly determine the method of attachment. With the use of cold welding glue for linoleum, smooth and strong joints are created that can withstand heavy loads. Let's take a look at what this tool is and take a closer look at the features of use.

Description and purpose

Cold welding is a simple and convenient method of gluing linoleum strips together using an adhesive. This tool works on the principle of a solvent. The edges of the linoleum melt during application, allowing easy adhesion to other parts of the flooring. Cold welding leaves fine seams almost invisible to the human eye. In terms of elasticity and strength, such seams are in no way inferior to the main linoleum sheet.

The purpose of cold welding is to reliably glue any type of linoleum, whether it is installing a new coating or repairing an old one. Benefits include:

- visually invisible monolithic seams;

- no need for professional skills and specialized equipment for work;

- low expenditure of funds;

- minimum time consumption;

- glue complex seams of any configuration and thickness;

- democratic cost.

Compound

Before you start working with "Cold welding", you need to take into account that its composition is poisonous, which means that precautions should be taken.

Solvent

The most commonly used solvent is tetrahydrofuran, a chlorine-containing substance that effectively melts polyvinyl chloride.

Adhesive

Filler adhesive is the liquid version of PVC or other polyurethanes.

How to choose the right one

When choosing a "Cold welding" adhesive for linoleum, several points should be considered.

Cover age

For linoleum, which was recently purchased, you can use adhesives of liquid consistency. It is recommended to “weld” a coating that has been on the floor for a long time using more viscous means - they contain a minimum of solvents in their composition, but are characterized by increased reliability.

The quality and shape of the cut of linoleum

For work with regular strips of linoleum, the composition and consistency of Cold Weld is not of primary importance. For complex, irregular and angled divergent joints, an adhesive composition with a high polyvinyl chloride content is required.

Carefully filling each corner of the joint with linoleum will prevent the flooring from moving in the future.

The experience of the person who will do the work

In the absence of experience with cold welding glue for linoleum, it is recommended to choose a product with a high content of polyvinyl chloride. Due to its high viscosity and density, it easily fills the joint, and also compensates for the inaccuracies that were made when cutting linoleum.

How to use

Before starting to work with the "Cold welding", it is necessary to select auxiliary tools and study the sequence of actions.

What is needed for gluing

To complete the job, you will need a number of tools:

- a long metal ruler that has a flat shape and does not warp;

- masking tape;

- sharp knife for cutting linoleum sheets;

- plywood, heavy cardboard or a piece of old linoleum as a backing, which should be placed directly under the seam.

In addition to working tools, you should also take care of the availability of personal protective equipment - a mask and special gloves.

Procedure

Work on "welding" linoleum must be carried out in a specific order in order to obtain a reliable result and avoid errors.

Sewing training

Competent formation of joints and seams provides a strong and reliable connection due to uniform filling of the gap with glue.

For this you need:

- Apply two sheets of linoleum with an overlap of five centimeters on top of each other, having laid a substrate under them.

- On the sheet that will be on top, make a mark on the location of the seam - in the very center of the overlap or with small deviations to the side.

- Placing a metal ruler along the future seam above two pieces of linoleum, make a cut along the material. When two pieces of linoleum are cut at the same time, the joint is as even and barely noticeable as possible.

Base and seam cleaning

Before starting the process of cold welding, it is necessary to clean the surface of the floor from dirt, remove the remnants of the previous coating and vacuum it thoroughly.

Linoleum parts to be glued must be well dried. Due to the presence of aggressive chemical components in the cold welding glue, the edges of linoleum must be reliably protected against corrosion. For this, the edges of the two floor coverings are covered with a wide masking tape, with the exception of a few millimeters left for the application of the glue.

Cold welding application

There are two ways to apply "cold welding" for linoleum.

In the first case, first grease the edge of one of the linoleum canvases with glue and apply it to the floor, then the second edge. Having tightly laid the edges of the coating next to each other, level and smooth the resulting seam.

The second method requires the simultaneous application of glue to both edges of the linoleum through a standard tubular nozzle. At the junction, the linoleum structure will become liquid, after which the edges will begin to merge.

Remove excess glue

When you use more adhesive than necessary, it may come out onto the joint surface. Until the edges are welded to each other, you should not pay attention to the remnants of glue, so as not to violate the integrity of the seam and not cause the linoleum to peel.As soon as the "cold welding" dries, you need to cut off the excess glue that has flowed onto the surface of the coating and repeat the procedure a day later.

Review of the best brands

Before buying high-quality and reliable liquid welding, you should familiarize yourself with the current offers of the best leading manufacturers.

Axton

This adhesive made in Poland is presented in tubes of 60 grams. This quantity is sufficient to treat five linear meters of floor surface. Provides an even, even and smooth application without nasty bubbles or wavy effects. Dries quickly. The maximum slot width is three millimeters.

Since the package has a thick spout and is not equipped with a needle, it can be difficult to apply the adhesive to high density seams.

Lincol

Linocol glue from the French manufacturer Bostic is available in 50 milliliter sachets. Thanks to the practical attachment, it is used for seams of different widths. It dries in half an hour and reaches full polymerization in six hours, at an air temperature of +20 ° C.

Sintex

Inexpensive adhesive from Spanish manufacturers. Designed for linoleum and other PVC products. Provides a tight bond that is protected from dust and dirt.

"Tarkett"

Tarkett cold welding glue from German manufacturers is intended for all types of linoleum flooring, including multi-layer and unevenly cut edges. The product tube is equipped with a high-strength metal needle, which has a comfortable shape, is protected against clogging and is not prone to breakage.

Homokoll

Household adhesive. Suitable for all types of PVC. It is used for bonding floor coverings (linoleum, vinyl tiles), as well as for connecting rigid PVC pipes.

"Forbo"

Liquid compound Forbo adhesive is intended for welding linoleum seams, as well as soft corners and polyvinyl chloride baseboards. As a result, a homogeneous compound of increased density is formed.

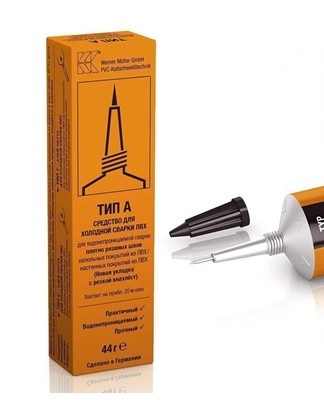

Werner Müller

The product of well-known German manufacturers meets international quality standards. Available in three versions.

A-Type

It is characterized by quick adhesion and the ability to glue joints with uneven edges. Can be used to overlap linoleum sheets. For 20 running meters of the joint, 44 grams of funds are spent. Not suitable for welding old linoleum flooring.

Type-C

It is used to bond all PVC coatings due to its strong softening properties. It hardens within fifteen minutes of application.

T-type

This is a specialized version of the glue, intended for welding seams of loosely cut linoleum. The initial setting takes place within thirty minutes, thanks to which it is possible to correct the position of the floor covering. The resulting seam has high strength. The tool can be used at air temperatures up to +16 ° .

Rico

Rico Linoleum Cold Welding Agent contains human-friendly polyurethane foam and artificial rubber. Provides seamless and stable seams that can withstand temperatures ranging from -40 to +60 degrees.

"Second"

Household glue "Secunda" is suitable for cold welding linoleum, as well as other hard and soft PVC products. Creates a neat transparent coating with high strength and elasticity.

What determines the expense

The consumption of cold welding is influenced by parameters such as the type of adhesive and the thickness of the floor covering. The thicker the coating, the more funds will be needed.The average consumption of an adhesive mixture belonging to type A, a seam with a length of 25 running meters is 50-60 milliliters. Type C tools for the same length seam will require twice as much.Measuring the length of the seams will allow you to accurately determine the required amount of adhesive mixture.

Additional tips and tricks

- Ensure good air circulation by leaving the doors and windows in the room open. Work to be performed exclusively with goggles and a respirator.

- Do not leave the tube with the product open for too long. It is not enough to put a stopper on the spout, in addition it is necessary to insert an awl or a needle of suitable size.

- For coatings on thick felt or polyester backing, as well as on multilayer sheets, high melting point type T adhesives are used.