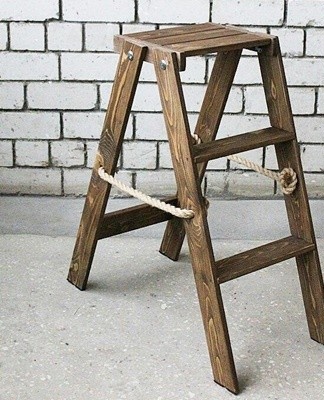

Step-by-step instructions for making a wooden stepladder with your own hands

Self-made stepladders perform several functions: they are necessary for owners during repairs, and also become a decorative element if they are not used for their intended purpose. When repairing, wooden or metal ladders are used, which can be easily made independently using simple diagrams and drawings.

The choice of material for self-production

The best option is wood. This material has characteristics:

- Strength. Ability to withstand mechanical stress.

- Hardness. Ability to resist bending.

- Wear resistance. Wear resistance, which determines the service life of a product made from the selected type of wood.

Wooden ladders are much easier to make yourself, unlike metal structures. An important condition is the correct selection of material.

Pine

Easy to handle lumber without additional factory attachments.It retains its physical and chemical properties for a long time. The flexible structure of pine makes it possible to use all coating products: varnishes, stains, paints.

Spruce

According to experts, spruce structures hold fasteners well. This is made possible by the special structure of the spruce wood.

Oak

The most expensive type of wood, which is used to make a ladder only if the structure performs a decorative function. Oak products are strong, durable and fit into any interior.

Birch

Birch ladders can crack over time, become dry in the middle, but they look great and can be decorated. Birch products are lightweight, easy to store, and also used as a flower stand.

Cedar

A dense and durable material that lends itself well to carpentry. Cedar products can be used for centuries. Cedar is almost never used for making stairs or stands, as cedar wood has a high cost and is intended for the production of luxury carved furniture.

aspen

Homemade aspen stairs are not durable. Aspen begins to rot if it stands for a long time in a room with high air humidity.

Linden

Linden wood is often used for interior decoration. Basswood stepladders are lightweight and durable.

Larch

Larch is most often used for the manufacture of rough structures, since the material is difficult to process. Deciduous stairs are suitable for large rooms.

Preparatory work

Before starting construction, prepare materials and tools. The wood for the ladder must be pre-dried. This condition helps prevent early damage to the wood and increases shelf life.

For processing wood, it is necessary to prepare special tools, as well as paint or varnish with which the steps are covered.

Varieties

There are several types of multi-story stairs that you can design yourself.

mini chair

This is a small step stool that can be used for small spaces. The chair is made in height from 70 centimeters to 1 meter. On the top step you can stand with your feet or sit and work at the table. The mini high chair can be used as an ordinary chair.

rack platform

The peculiarity of the stand platform is that the upper step is fixed with a special device. The fixed platform allows you to freely stand on it and place additional devices. The height of the platform support reaches 1.3 or 1.5 meters. You can store such a platform in a folding form, leaning against the wall of a storage room, dressing room or basement. To fold the ladder, simply release the latch, lift the platform and bring the two sides together.

Unilateral separation

The partition stepladder with one-way ladder is designed as a support. On one side there are steps and on the other side a support wall. A stable platform is attached to the top step. It is customary to use such a support as a decorative element of the interior. It is difficult to collect and store in small spaces. The design is not particularly stable.

Two-sided separation

A double-sided platform assumes the presence of equivalent steps on both sides. This support is convenient to use for pasting wallpaper. One person can stand on each side. Due to the fact that both sides are located symmetrically with respect to the center line, it is easy to assemble and store folded.The ladders separated on both sides do not exceed a height of 2.3 meters.

Rolling

The name speaks for itself. A stepladder on wheels is made to work in homes with high ceilings. Escalators are used in libraries, museums, exhibition halls.

Most often, escalators are products with a maximum number of steps, designed as a spaced one-sided support. The wheels are fitted with a locking mechanism which can be easily removed when the ladder needs to be moved to another location.

How to make a simple wooden stepladder with your own hands

A person familiar with the basics of construction can make a wooden stepladder on their own. To do this, you need to select the type of stairs in advance, select materials and make all the necessary measurements.

Reference! To build a ladder, you will need a set of construction tools.

Determining the configuration and size of a homemade stepladder

Before starting the stepladder manufacturing process, it is necessary to calculate the input parameters. The first step in the calculation is to estimate the height of the future product.

| Settings | Quantity |

| 2.9 meters | 4 steps |

| 3.1 meters | 5 steps |

| 3.3 meters | 6 steps |

| 3.5 meters | 7 steps |

The number of steps is often calculated based on how you plan to use the ladder. If the staircase is a decorative element, it is enough to plan the construction of three marches. For repair work in houses with high ceilings or garden work, high stairs are constructed from 6 or more steps.Garden supports are most often designed as double-sided ladders, so it is more convenient to work on them, then fold them up and store them.

Notches are made on the vertical support of the staircase, which implies the location of each successive step. One of the nuances of the correct approach to preparation is taking into account the tread indicator. A step is the distance between the edges of a step. Size 45 is taken as an example for calculation. In this case, the length of the steps becomes shorter, the higher the step.

Reference! It is customary to leave a distance of 20 to 30 centimeters between the steps.

The choice of the bar section

The cross section of the bar can be square and rectangular. For the manufacture of stairs, both types are used. Most often, a bar with a total indicator of 60 by 40 millimeters is used for supporting posts, and a bar with a section of 60 by 30 millimeters is used for steps and crossbars.

Reference! The standards of the section take into account the type of wood species: for conifers and hardwoods, the indicators may be different.

Choice of additional components

To make the staircase stable, beautiful and durable, additional elements are selected:

- Metal knitting needles or screws. These elements are necessary for more reliable fastening of the steps. Knitting needles are inserted under the step, fixed with nuts and bolts. The thickness of the needles should not be less than 8 millimeters, otherwise the needles will begin to bend under the influence of the load. Screws can be used instead of metal spokes.

- Iron chain or nylon rope. These elements are designed to connect the two sides. They help hold the stairs together, keep the sides from sliding together.

- Nozzles or retainers. Pads are used to prevent damage to the flooring. They are placed on the stair legs and removed if used on the floor. Clamps are required for rolling structures.

- Swivel casters. This item is required for rolling structures. Manufacturers recommend using 360 degree rollers. This design allows you to use the ladder on any surface, even to climb stairs without much effort.

Assembly: step by step instructions

To make a stepladder with your own hands, you need to strictly follow the step-by-step instructions. All works can be conditionally divided into stages:

- The necessary parts are cut or cut according to the prepared templates.

- Where it is planned to install fasteners, holes, grooves and recesses are made.

- The surface of the wood is treated with special compounds and dried.

- Self-tapping screws are installed in the places of the fasteners, the fasteners are fixed.

- The surface is ground, errors made during processing are corrected.

- The last stage is the assembly of the stairs.

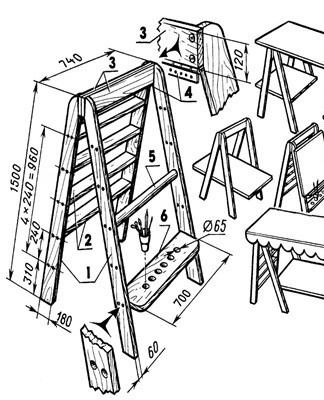

Additional drawings

To read the drawings, you must understand the special symbols. Furniture drawings are made according to the actual size parameters, all indicators are in millimeters. From the drawing of the folding ladder chair, you can see each element. The details allow you to see the staircase as it will become after

Most often, drawings made in 3D technique help to determine whether the width of the steps is correctly selected.If they are planned too wide, then it is possible to reduce the indicators during construction and make the stages more convenient for the owner.

Information! According to the three-dimensional three-dimensional drawings, you can choose the color of the paint, the type of finish of the finished product.

How to further process the finished product

It is customary to additionally process wooden stairs and stepladders. This stage of processing is called finishing. It terminates all previous processes. The topcoat provides strong adhesion to the parts and completes the decoration.

Before assembly, it is recommended to treat the wood with special antiseptic compounds to exclude the possibility of rotting and mold. To do this, use a stain.The composition of the stain impregnates the wood, creates a protective film and extends the shelf life of the wood. When the steps are screwed, the shaft can be treated with linseed oil. It is an oily liquid that is pre-coated before painting.

Then the finished product is covered with paint. If the stepladder is intended for decoration of the room, then it is recommended to cover it with paint of several colors in order to create interesting places. Wood carving is considered a special type of decoration.

Possible problems

Self-construction of a wooden staircase is associated with certain errors. To avoid problems, you need to study the recommendations of experienced specialists:

- When designing double-sided stepladders, distortions sometimes occur. This is because the holes on both sides are not drilled parallel. To avoid this mistake, experts recommend using long drill bits and drilling both holes at the same time.

- To reinforce the fasteners, use nuts with appropriately sized washers.Washers adjust the clamping force, adjust the strength of fasteners.

- The metal chain is replaced by a nylon cord. This facilitates construction, makes the ladder attractive and light.

- Experienced builders recommend using homemade electrical tape holders instead of foot nozzles. The legs are wrapped 2-3 times with adhesive tape - this will protect the floor from scratches.

A wooden stepladder can be made from these materials that are available to everyone. To make a strong and durable staircase, it is recommended to take oak or pine beams.