Types of adhesives for polypropylene pipes and rules for their use at home

Professional builders and home tradesmen install plastic plumbing, gas and heating systems. They are easy to transport and connect without soldering. The joints are hermetically fixed using a special adhesive for polypropylene pipes. Cold welding assembly technology is simple, so you can change the water supply yourself at home. It is enough to calculate the material consumption, the location of communications and choose the glue.

Features of polypropylene

Polypropylene is an unsaturated propylene hydrocarbon polymer, plastic at a temperature of 140 degrees. Polypropylene pipes are laid for cold water supply. Products made of metal-plastic alloys are suitable for hot water.

Pipes for domestic or industrial sewage do not rust, they are simply installed and repaired, and with high strength and durability, they are cheaper than metal pipes. The disadvantage of polypropylene is the expansion and reduction of service life under the influence of sunlight.

Varieties

Cold welding products differ in their reaction to heat.

Thermosetting

The composition includes epoxy, polyester and oligomer resins. Thermosetting adhesive cures by high temperature or hardener. The cured product can withstand heat, cold and shock.

To dismantle the structure, fixed with thermosetting glue, it will have to be cut.

Thermoplastic

Adhesives are made of rubber and become plastic at high temperatures. They are not used in hot environments. The hardened glue firmly binds the structural elements.

How to glue correctly

Polypropylene pipes are as strong as metal. The lifetime without leaks at joints is on average 30 years. So that during this time you do not have to repair the water supply or the heating system, you need to follow the technique of gluing the pipes. When done correctly, glued joints hold water just as securely as welded joints.

Individual elements

The advantage of polypropylene pipes is that a sudden leak can be quickly sealed:

- turn off the water supply, drain the water from the system;

- wait for the pipes to dry;

- clean and degrease the crack with acetone or alcohol;

- clean the surface with emery for better glue adhesion;

- apply the product with a gun and distribute evenly with a brush.

The edges of the crack should be moved apart so that the glue penetrates between them. After fixing the leak, wait 12 hours and apply low water pressure when starting the system. Otherwise, a crack may open due to a sharp increase in pressure in the pipe.

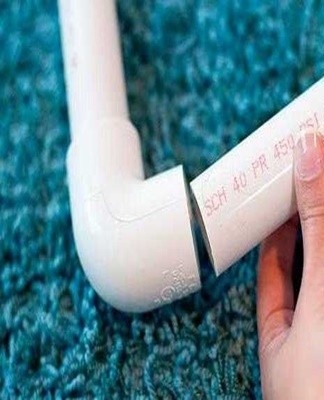

Pipes

Pipeline assembly procedure:

- mark and cut pieces;

- grind the ends;

- chamfer and degrease the inside and outside of the ends of heavy-wall reinforced pipes and fittings;

- arrange the structure according to the plan;

- fill the glue gun with the mixture;

- apply to pipe joints;

- evenly distribute the glue with a brush;

- wait for the time that is necessary according to the instructions for use of the glue;

- glue the joints well.

You can start the water supply or the heating system 24 hours after assembly. In order for the glue not to lose its properties, work should be carried out at a temperature of 5 to 35 degrees Celsius. It is best to smooth the adhesive layer with a brush with natural bristles. Synthetic lint can dissolve in the adhesive.

Once in the formulation, foreign matter can reduce the stickiness or strength of the product.

Review of popular brands and manufacturers

The polyvinyl chloride in pipe glue makes it look like plastic. For the flexible connection of hot water supply pipes, styrene-butadiene rubber is added. Thanks to an additive that increases the strength of the glue, the joints will resist water shocks and high water pressure. Methacrylate increases the resistance of compounds to alternating low and high temperatures.

Manufacturers add various substances to the main composition that affect the hardening time, transparency, consistency and service life of the glue. Different brands offer ready-to-use products or ingredients for the preparation of the mixture.

Cosmoplast 500

The one-component composition is used for the installation of household and industrial communication systems. Characteristics of the glue:

- suitable for joining parts at an angle of 45 degrees;

- chlorine, heat and water resistant;

- dries in 3 seconds;

- hardens after 16 hours at a temperature of +20 degrees.

The adhesive is applied to one of the two surfaces to be bonded. Less funds - liquid consistency. Therefore, the walls of the sealed crack can disperse under water pressure.

Dow Corning 7091

The adhesive putty has the following characteristics:

- liquid;

- transparent;

- resistant to temperatures up to +180 degrees.

The multi-purpose agent acts like glue when applied in a 5 millimeter layer. A dense paste 25 millimeters thick seals the cracks. Surfaces can be repaired within 15 minutes after bonding.

WEICON Easy-Mix PE-PP

The two-component composition includes acrylate. A high tack adhesive can be applied to uncleaned surfaces. The compound cures in 24 hours at room temperature.

tangit

Properties of German means for the installation of water pressure communications and gas pipelines:

- transparent;

- dries in 4 minutes;

- gains strength after 24 hours.

The adhesive is certified for potable water applications. A brush is included in the package.

Genoa

The American manufacturer offers a universal tool for installing all plastic pipes and fittings. The glue dissolves the top layer of the surfaces and, after hardening, joins them into a continuous solid structure. The composition is also suitable for mounting water supply systems for swimming pools and drinking water.

Griffin

The Dutch brand of adhesives and solvents offers a special rapid curing agent for the assembly of pipes, fittings and fittings. The liquid emulsion connects parts with a diameter of up to 40 centimeters and fills voids with a thickness of 0.6 millimeters.

Gebsoplast

Sewer and water pipes installed with French glue-gel will withstand a pressure of 40 bar and temperatures of up to 90 degrees Celsius.

Product properties:

- does not flow on a vertical surface;

- does not contain chlorine;

- hardens in 24 hours;

- brush as a gift.

Pipes of different purposes and types are connected with glue:

- household drains from dishwashers and washing machines;

- systems with valves;

- stormwater drainage channels;

- underground communications;

- industrial pipes.

The product is produced in plastic and iron canisters of 250, 500 and 1000 milliliters, as well as in a tube of 125 milliliters. The manufacturer does not recommend shaking the glue, as the product liquefies.

Choice criteria

When choosing a glue or sealant, you need to take into account the features of the work:

- cleanliness, room temperature;

- water temperature, pressure in the pipes;

- possible displacements of pressure pipelines from the inside or from the outside.

Pipes in areas with different temperatures are often connected by means of different resistors. Glue for the arrangement of the cold water supply system will not work when installing the hot waste disposal. The packages indicate the allowable pressure in the pipe that the adhesive will withstand. A composition designed for a large number of bars is more expensive. Buying cheap glue with high drop heights or frequent pressure fluctuations causing the pipes to move is a dubious saving. To repair leaks, you will need a stronger and more expensive compound. Therefore, you should immediately purchase glue that matches the pressure of the water supply.

When choosing an adhesive, you need to consider its properties:

- how many minutes can you keep the jar open;

- method of preparing the mixture;

- color of pipes and glue;

- the consistency of the mixture.

The colorless composition is suitable for white and gray communications. To prevent the glue from spreading and the parts to fit easily, it is better to choose medium-viscous or gel formulations. The container with glue can be opened for an average of 5 minutes. When preparing a mixture of individual components, it is important to correctly calculate the proportions. An incorrectly prepared solution is a waste of time and materials. Therefore, for self-assembly at home it is better to purchase ready-made glue. Most modern assembly tools do not contain toxic substances. But when choosing an adhesive, you need to study the composition.

Additional tips and tricks

Observance of the joining technology and the correct selection of materials will help to glue the pipes well:

- before applying glue, you need to firmly insert the end of the pipe to be connected into the groove and put a mark so as not to fit the ends less tightly;

- mixing the compositions of two components after preparing the parts;

- to increase the adhesion of the composition to the surface, the end of the product is treated with fine sandpaper;

- you can not clean the edge with a file, a grater, so as not to damage the part;

- select the glue for the pipe material according to the production marking.

To check the strength of the future structure and practice assembly, you need to glue a test sample.