Varieties of adhesives for polycarbonate and do-it-yourself rules of use

Choosing the right adhesive for polycarbonate can achieve good results. With the help of this substance, it is possible to fasten different elements to each other, achieving a strong and reliable fixation. Today there are many types of adhesives on sale, which differ in composition, color and setting time. It helps you choose the right option and get great results.

What is the building material used for

Polycarbonate is considered a tough plastic that has a whole list of important characteristics. It is used in various industries - construction, advertising, industry. Polycarbonate products are considered durable and lightweight. They are distinguished by reliability and excellent appearance.

In the manufacture of polycarbonate products, it is necessary to glue the individual components together to obtain a single product.In order to obtain excellent aesthetic characteristics, it is recommended to select the appropriate adhesive for fixing this material.

A quality product allows to achieve high strength of the product and maintain the characteristics of the material, making it resistant to mechanical and climatic factors.

Features of working with polycarbonate

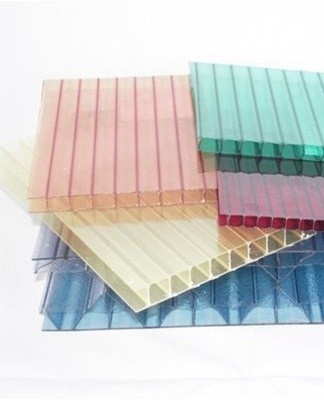

In order to successfully work with this substance, it is recommended to take into account the characteristics of the substance. Polycarbonate can be cellular and monolithic.

Cellular

This type of material is characterized by a porous structure. It is widely used. Such polycarbonate is often used for the production of canopies or roofs. With its help, fences and gazebos are made. Porous polycarbonate is often used for decoration. The material is considered light, but at the same time it is very durable. It is able to withstand strong temperature fluctuations - from -45 to +120 degrees. The substance is considered refractory. It does not burn. In case of fire, the substance melts without the release of harmful components.

It is allowed to fasten polycarbonate sheets with profiles. They can also be attached to fabric, wood, glass or paper. It is allowed to fix the material on metal parts. The substance can be glued with an overlap or butt. If high strength is required, use the overlap fastening method. In other cases, it can be done end-to-end. Before carrying out the procedure, the joints must be degreased. This is done with isopropyl alcohol.

Monolithic

This plastic is actively used for cladding buildings. The substance is ideal for solving these problems.It has good strength and can be used without frames. The material is used for the manufacture of various podiums and ramps. The substance has good light transmission.For this reason, it is allowed to use it to create spectacular designs with interior lighting.

This type of polycarbonate is characterized by high strength. It is allowed to drill, saw, cut. Further, the substance is held together using ultrasonic or pulse welding. For this purpose, it is permissible to use hot electrodes. The substance is suitable for the manufacture of signs and road signs. It is used for the production of showcases and exhibition materials. Monolithic polycarbonate is easy to paint.

Plastic is used where good strength and durability are required. The composition provides good sound insulation. The material does not burn and is resistant to high and low temperatures. It can be press or vacuum molded. If high adhesive strength is not required, monolithic polycarbonate can be attached with conventional laminate adhesives. In other cases, it is worth using silicone adhesives or two-component substances. Flat surfaces can be secured with acrylic foam tape.

Classification of adhesives

Adhesives differ in different characteristics. This helps you choose the right option based on your tasks.

On appointment

Considering the purpose, compositions suitable for fixing honeycomb or monolithic plastic are distinguished.

By the principle of action

According to this criterion, one-component and two-component compositions are distinguished. The first category is used for fixing simple products. Two-component substances are used for volumetric structures that require a high degree of reliability and strength.

By membership

Depending on the components used to create glue, the following types are distinguished:

- silicone;

- polyurethane;

- acrylic foam;

- ethylene-vinyl acetate;

- hot hardening.

By the complexity of use

To create a small and not too strong bond, it is permissible to use EVA or a hot curing agent. They are applied quite easily - with the help of special guns. For an extra strong hold, use a polyurethane adhesive.

By the degree of transparency

All adhesives differ in their transparency. The choice of color and texture is especially important when attaching clear plastic.

By solidification time

The solidification time is also different.

The longer this process takes, the more adjustments can be made to the finished product.

By viscosity

When choosing a fastening material, be sure to consider the degree of its viscosity. It is chosen according to the product to be fixed.

How to glue with your own hands

In order to glue the products yourself, it is recommended to take into account many features. The weight of the structure is particularly important.

Lightweight constructions

For fastening light elements, as a rule, one-component adhesives are used. For this, heat guns are suitable, which have special rods or ready-made compositions.

Hot curing adhesive

To quickly glue fragments of monolithic material, it is recommended to use a heat gun. Such a device includes glue sticks. The procedure involves melting the rods. During the procedure, it is possible to apply in doses of hot glue of a liquid consistency.

The substance provides reliable fixation of polycarbonate on various materials - wood, metal, glass.

There are many effective products of different prices on sale. Professional models have glue spray. This allows large areas to be bonded quickly with minimal material consumption.

cold hardening

For gluing small elements, it is permissible to use a substance that does not need to be heated before use.Today there are many one-component compounds on sale that provide the resistance of joints to various influences . At the same time, these tools help preserve the sophisticated design of the product.

The most popular and high-quality products are products of German companies Weiss and Röhm GmbH. Thanks to the wide range of products, it is possible to select the adhesive with the required performance. It can be transparent or white, it differs in density. There are compositions with rapid or long solidification.

With other materials

If you need to glue polycarbonate sheets together with other materials, it is recommended to use double-sided tape. So, the 3M company produces a sample 4830, which provides excellent adhesion. This is achieved with an acrylic foam adhesive.

Before attaching the tape, be sure to thoroughly clean the materials and degrease the surfaces. Thanks to this, it is possible to achieve excellent results. For fixing small objects made of monolithic material, it is worth using a one-component composition. However, the best effect is achieved through the use of a polyamide-based heat gun.

With a high operational load

Silicone glue is used to fix structural elements that require high seam strength. It is also allowed to use a substance based on polyurethane.Special equipment is required to apply the two-component polyurethane agent. Its role is played by a pistol equipped with replaceable cartridges. This type of glue allows to obtain a high strength of the structure and the transparency of the seams.

Silicone glue is very effective. It reliably fixes sheets and elements made of monolithic material. Thanks to the use of this substance, structures are able to withstand significant loads.

Review of popular brands

There are many popular brands today that manufacture different types of adhesives.

Cosmopur K1

It is a one-component polyurethane compound that is very effective.

Acrifix 190

It is a two-component adhesive that has a transparent consistency.

Cosmoplast 460

This two-component substance produces a seamless seam.

HE 17017

This composition is produced by the Chinese company EngineeringChemical Ltd.

ET 1908

Another very effective Chinese remedy.

Acrifix 5R 0194

It is a five-component substance that has a viscous consistency and is made on the basis of methyl methacrylate.

Common Mistakes

For gluing polycarbonate, it is not recommended to use adhesives based on alkalis and solvents. When attaching plastic, they lead to the destruction of its structure. As a result, the material darkens, bubbles and cracks appear on it. It is also a mistake to use adhesives with solvents. These components pose a hazard to molded plastic, causing it to crack.

Also, it is not recommended to use homemade formulations. They will lead to the fixing of surfaces, however, a rough seam will not be able to withstand strong mechanical stress. Glue containing dichloroethane is not suitable for general use.This solvent poses a great danger to the human body and has a carcinogenic effect. These substances can only be used under industrial conditions.

Additional tips and tricks

Before gluing polycarbonate products, you should familiarize yourself with the key rules:

- It is recommended to first clean the surface with isopropyl alcohol. This cleans and degreases the material.

- Use a special gun to apply glue to the surface. Instead of this device, it is permissible to use a syringe or vial with a tip.

- When choosing an adhesive, one should take into account the presence of solvents.The type of material that will need to be fixed is also important. If you need to glue polycarbonate to metal or wood, you need to choose special substances.

Polycarbonate can be bonded with different types of substances. To choose the optimal composition, it is recommended to take into account the type of construction and the characteristics of the materials used.