How to make a metal and wooden swing with your own hands, drawings and step-by-step instructions

Installing a swing set in a suburban backyard adds a decorative and functional element to the landscaping. Having built a garden swing with your own hands, you can embody original design solutions.

Content

- 1 Varieties

- 2 main Features

- 3 Advantages and disadvantages of a homemade metal swing

- 4 Drawings and diagrams of a garden swing with dimensions

- 5 How to make a frame from a profile pipe correctly

- 6 How to assemble a wooden seat step by step

- 7 How to make a visor

- 8 Decoration and maintenance

- 9 Manufacturing process of wooden swings

- 10 Tips and tricks from the masters

- 11 Examples of ready-made homemade benches

Varieties

There are several types of garden swings. Structures differ in material of manufacture, appearance and performance.

In wood

The most common option is a wooden swing. The texture of the material harmoniously complements any style of landscape design. Using a tree to build a swing is beneficial due to its ease of processing, affordability, durability and decorative appearance.

Made of metal

A metal swing is considered a more reliable and durable option. For the manufacture of a structure, various elements are used, each of which has its own purpose.

Corners

The base of the swing seat is a base made of a steel wedge. To make a base with a comfortable backrest, it is positioned at an angle of 120 degrees to the seat. To create the correct bend of the corner, a triangular cut is made on it.

Square profiles

The frame part of the swing is made from a rectangular metal profile using the welding method. The side elements are connected at the edges by horizontal bridges. The connecting section should be in place of the elbow of the structure.

I-beams

The I-beam is a metal profile, for the production of which carbon and low-alloy steel are used. The elements have a cross section in the form of the letter H and are distinguished by an indicator of increased strength.

The use of I-beams increases the reliability of the swing and allows it to withstand heavy loads.

Pipes

A metal swing made of profile pipes with a cross section of 40 x 40 mm can withstand a weight of up to 200 kg. The optimal thickness of the pipe is 2 mm, diameter - 7 cm. By increasing the diameter, you can increase the resistance of the product to loads.

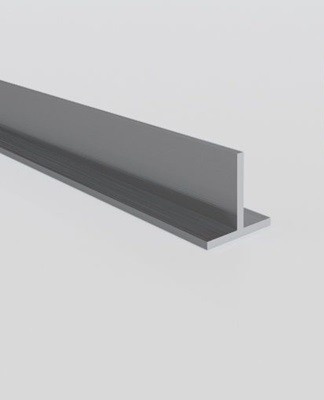

Bull

Taurus is a kind of solid profile, for the production of which aluminum or its alloys are used. The cross section of the mark does not have an internal cavity, and its shape takes the form of the letter T. The list of the main characteristics of the aluminum mark includes:

- increased stiffness coefficient;

- strength and long period of operation;

- resistance to rust formation;

- high load capacity with low weight.

main Features

Regardless of the material of manufacture, a garden swing must meet a number of standard characteristics. With full compliance with the specified parameters, the product will be as comfortable as possible in everyday use.

Lifetime

Subject to high-quality assembly, the swing can be used for several decades.

To extend the life of the structure, it is important to use high-quality materials in the work and to follow the instructions for self-assembly exactly.

Practicality

In order for the swing to serve not only as a decorative element, but also as a practical one, it is worth paying attention to a number of small things when assembling it yourself. On the side handles of the swing, you can build cup holders and recesses for storing various small things. An important practical capability is the swing's ability to fold out and convert into a spacious outdoor bed.

If the swing is not under a canopy, then it is worth equipping it with a water-repellent roof. It is also worth giving the option of covering the swing with a protective cover in case of heavy rain or to ensure safety in winter.

Reliability

Different models of garden swings are able to withstand loads from several tens to several hundred kilograms. Design reliability depends on the materials used.

To increase reliability, the lower base is reinforced with profile pipes.

Budgetary

Even inexpensively, it is possible to build a garden swing yourself.The most budgetary option is the wood variety. In order to reduce costs, it is important not to save money by purchasing poor quality material, as this may affect the life of the product.

Variety of modifications

The garden swing can be transformed into a bed. In these varieties, the back is folded to the end. There are also models in which the backrest is not fully retracted, which also makes operation more comfortable and allows you to sit in a lying position.

Advantages and disadvantages of a homemade metal swing

The self-assembled metal garden swing has a number of positive and negative characteristics. The main advantages are:

- structural strength and ability to withstand heavy loads;

- aesthetic appearance;

- the ability to modify the swing and add the ability to unfold.

The list of product shortcomings includes:

- the likelihood of a squeak when tipping over;

- the appearance of rust with frequent contact with water;

- large weight of the material, which complicates the assembly process.

Drawings and diagrams of a garden swing with dimensions

Before assembling the swing, it is necessary to prepare a drawing and a diagram indicating all the dimensions. The dimensions of the structure and other characteristics depend on the type of product selected.

Conventional

The standard type of garden swing assumes a frame height of 2.1 m, a height from ground level to a seat - 0.7 m, and a width of 1.4 m. The conventional swing has a simple shape without adding additional elements.

For the gazebo

The swing garden gazebo consists of several benches facing each other. A table is fixed between the benches.It is important not to attach the seats rigidly to the base, but to hang them from the upper beam. The dimensions of the structure are determined individually, based on your own wishes.

For the porch

The design of the porch does not differ from the standard design, and the only requirement for assembly is to take into account the load on the base. The dimensions of the product are calculated based on the free space on the porch.

Pergolas

The pergola is a canopy without a foundation on four supports without walls or a roof. There are several types of pergolas:

- monumental - used mainly for decorative purposes on the site or above the entrance to the main building;

- pergola-gazebo with a bench or swing, designed for relaxation and comfortable pastime;

- pergola support for climbing and climbing plants.

As a rule, a pergola of any type has a square shape. The optimal height is 2-3 m, the width on each side is 3-4 m.

Double-legged logs

For the manufacture of a double-legged variety, logs about 2 m long and 10-15 cm in diameter are used. The logs are crossed in the right places, holes are drilled and knitting needles are threaded with a diameter of 10 mm are inserted. When constructing this type of swing, the side posts should be symmetrical.

To make the structure more reliable, double inclined stops are added.

Fantasy for two

If you want to create a creative version, you should consider the original design for two. This design is made in the form of a small gazebo with a canopy. Seat width is about 1.5m, height is 2-2.5m.

Beautiful with forge

The use of forged elements gives the product a decorative look. Most often, forged side parts and an upper base are built.According to your own wishes for the design, you can implement any solution on which the visual perception and dimensions will depend.

of pallets

The remaining pallets after construction work can be used to create a product. Wooden surfaces are treated with protective equipment and connected at right angles or inclined. To give reliability to the connection, metal corners are used.

For a standard model, two pallets with a dimension of 1.5 x 1.5 m will suffice. Thick load-bearing beams are placed under the pallets, which take up the load and prevent breakage at the attachment points.

tires or tires

Car tires or unwanted tires can be used as a seat on a garden swing. The rubber tire is attached to the frame with strong ropes. For reliable fastening in a horizontal state and to prevent accidental overturning, it is worth making a triple mount. At the top, the tire is attached to a horizontal bar, which is a wooden beam or a metal beam.

Due to the limited dimensions of the structure, it is designed for one person. To diversify the appearance of the product and add originality, you can paint the visible part of the tire with a special paint and varnish it on top.

Folding

The folding design allows you to tilt the backrest and turn the product into a bed. It is recommended to mount a canopy above the folding structure to provide additional comfort. The shelter will provide protection from sunlight and light rain.

From a bar on chains

The combination of wooden beams with metal chains creates a solid structure that can withstand heavy loads. On both sides of the seat, two chains are attached - at each corner.This option is considered one of the most reliable.

swing bed

The bed frame is a type of folding frame. To sleep comfortably on such a swing, you need to correctly calculate the dimensions of the seat. As a rule, the product is made from 2 x 3 m, so two people can lie on it freely.

How to make a frame from a profile pipe correctly

For the manufacture of the frame, the profile tubes are welded to each other. Next, jumpers of smaller section are welded between the supporting elements. At the top of the corner of the pipe fitting, the top is cut to support the crosspiece.

How to assemble a wooden seat step by step

To assemble a wooden seat, you must first impregnate the material with protective agents. The treated boards are connected with fasteners and hung on the frame.

How to make a visor

The simplest roof option for construction is a fabric awning. All you have to do is pick up a cloth of the required size and hang it on the top base.

Decoration and maintenance

For daily care, it is enough to wipe the product from dust and dirt. Forged items and climbing plants can be used as decor.

Manufacturing process of wooden swings

The assembly of the wooden variety is carried out according to the standard instructions. It includes the following steps:

- assembly of the frame from beams;

- assembly of seats by gluing treated boards;

- securing the base to the frame using ropes, chains or alternative retainers.

Tips and tricks from the masters

To secure the swing, it is recommended to use a welding machine. Welded elements do not even break under high loads, which is especially important for children's swings. During the manufacturing process, the instructions must be strictly followed in order to avoid common mistakes. One of the main recommendations is to purchase high-quality materials that will extend the life of the structure and will not collapse under negative external influences.

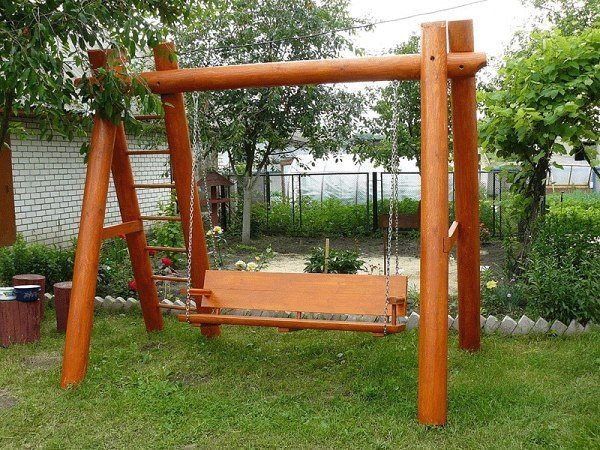

Examples of ready-made homemade benches

To start creating a swing, you need to get acquainted with examples of ready-made products. This will allow you to find an interesting idea or complete your own idea.