Description and scope of Akfix glue, instructions for use

New materials are needed to speed up construction and renovation work. Perfect for express bonding Akfix 705 glue. With such a tool you can save time and money. In this case, the result will be excellent. It is advisable to use Akfix 610 liquid nails for repairs and glue.

Description and scope

The Akfix 705 adhesive set consists of 2 components: a 50 ml bottle with a viscous polymerizer glue and spray-activator with a volume of 200 ml.

Use the kit to:

- quickly glue furniture from solid wood, MDF, chipboard;

- glue PVC panels;

- manufacture parts of mechanisms in the automotive, electrical industry;

- rubber, polyurethane, plastic, fiberglass, hydrocarbon steel, aluminum repair products.

The glue is suitable for express bonding of stone products. It is used in the repair of screens, keyboards, remote controls.

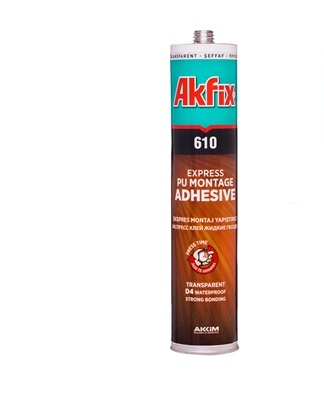

Liquid nails based on Akfix 610 polyurethane are used in repair and construction, as a one-component material is able to firmly glue any surfaces, except for propylene, polyethylene, Teflon, ABS .

Professionals use an adhesive composition for the manufacture of wooden frames, doors, furniture sets.Liquid nails are irreplaceable when installing aluminum corners on containers, cars, windows.

Composition and properties

The glue product contains substances that can firmly bind any surfaces, parts of an object, mechanism. The properties of Akfix 705 glue are excellent, which helps the product gain popularity among professional builders and ordinary consumers.

"Acfix 705"

Cyanoacrylate adhesive first appeared in 1958. Cyanoacrylic acid esters are now part of many repair products. Such as Akfix 705 are used in construction, industry. The glue does not contain solvents, therefore, a viscous gel should be used for gluing with an activator, which is applied directly to the adhesive. Entry is instantaneous. This is due to the fact that the components of the activator speed up the process of carrying out a chemical reaction up to 2-3 seconds. At the same time, the quality of the gel does not change: it remains transparent and durable.

The activator is based on isopropanol and additives to improve the functions of the chemical.

"Acfix 610"

Liquid nails are polyurethane based. Advantage of glue in:

- transparency;

- excellent viscosity;

- economical consumption;

- high-quality connection;

- resistance to moisture, temperature extremes, chemical influences;

- safety.

Bonding surfaces with liquid nails is quick and easy. Adhesive does not run, allowing surfaces to be joined vertically or upside down.

General rules and instructions for use

Before using super glue, prepare the surfaces to be bonded. It is important to clean them from dust and dirt.If they are rough, it is not scary, it will not affect the quality of adhesion. To use the Akfix 705 glue kit correctly, you must apply an activator to one part of the joint and a gel to the other.

They quickly connect the parts, which will allow the composition to polymerize in seconds.

Apply the activator spray in a thin layer from a distance of 30 centimeters. Remember that the substance can have a negative effect on varnished surfaces, thermoplastic materials. The method of applying the activator spray on the gel can also be used. First, it is covered with a thin layer of a viscous transparent adhesive, then quickly sprayed on top with an activator liquid. Immediately press the surfaces to be bonded.

Liquid nails with one-component glue Akfix 610 are applied to part of the glued objects, firmly pressing the parts to each other. Do not cover the surfaces with a thick layer of glue. The adhesion will be better with a thin and uniform application of 0.2 millimeters.If excess glue comes out, the drops are immediately removed, preventing them from hardening. You can use acetone for these purposes.

Precautionary measures

The use of cyanoacrylate adhesives does not adversely affect human health. When working with Akfix 705 or 610 ensure that:

- ventilate the room;

- eye protection with goggles;

- prevent the substance from penetrating the skin.

It is not recommended to tear the glue particles from the skin, otherwise you may hurt yourself. In case of sticking, carefully remove the particles of the product with a thinner.Minor adhesive residue will disappear on its own over time due to the release of grease from the skin pores.

Do not put cotton gloves on your hands, as the glue will heat up the natural material and break it down. Inhalation of cyanoacrylate vapors causes asthma symptoms. Therefore, it is desirable to protect against the ingress of ethers into the body.

Additional tips and tricks

When working with glue based on cyanoacrylate, it is necessary to take into account that:

- It is best to set the humidity in the room during work in the range of 40-70%. When it is too dry in the apartment, the adhesion will be weak, and you will have to wait a long time for the bases of the materials to stick together. Excessive moisture will cause the adhesive to cure, but the bond strength will be poor.

- The adhesion of the glue decreases if the ambient temperature drops below 20 degrees Celsius.

- Base metal parts are well connected with glue.

- When gluing the rubber, a new cut must be made on both parts of the object. Glue is applied to one of the parts, then gently join. Adhesion occurs instantly.

- It is possible to achieve cleanliness of glued surfaces using sandpaper, washing, steam treatment.

Before using Akfix 705 or 610 glue, it is necessary to test the effect of the substance on the materials to be glued.