What is the best glue for repairing shoes at home

No matter how well made, all garments tear over time. This is also true for shoes, which tend to detach from the sole. Eliminating this defect usually requires the help of a shoemaker or the presence of specialized equipment. However, using shoe glue, you can glue the soles that have come off at home. Moreover, the effect in both cases will be the same.

Basic requirements for shoe glue

A high quality glue should have the following characteristics:

- glue the shoes securely;

- ensure the safety of the original appearance of boots and boots;

- fix loose parts for a long time;

- maintain the elasticity of the fixed parts;

- keep moisture and cold.

It is necessary to select the glue taking into account the type of material to be repaired. Otherwise, the composition will not meet the above characteristics.

Despite the fact that there are many similar products on the market, when choosing glue for shoes, you can be guided by the following rule: to restore summer boots, you need to take rubber products artificial, winter ones with increased frost resistance.

Reliability and durability

These two parameters are considered the most important. The life of the bonded shoe depends on the strength of the connection.

Water resistance

Due to the fact that the shoes are worn in different weather conditions, it is important that the glue does not leak water.

Frost resistance

This parameter is important for the glue used to hold autumn and winter shoes together. On the packaging of the purchased product there should be a mark indicating that the latter tolerates negative temperatures.

High degree of adhesion

Adhesion refers to the degree of adherence of materials. That is, the reliability of the connection provided by the glue depends on this parameter.

Lack of rigidity, elasticity

Shoes are exposed to increased stress. Therefore, it is important that the adhesive maintain normal elongation at the joints. Otherwise, under high pressure, the shoes will scatter again.

No harm to leather shoes

The skin is more and more demanding in terms of care. And a number of aggressive compounds, including glue, are capable of causing serious damage to this material.

Varieties

Depending on the area of application, adhesives are used for primary or secondary fixing.

For basic stapling

These compounds are characterized by increased strength and provide a long-lasting connection.

Subsidiary company

Auxiliary glue is used to strengthen the bond. Compounds of this type are applied to staples, threads, nails that hold shoes together. The auxiliary adhesive has less adhesion.

Secondary in nature

They differ in the least adhesion, and therefore are used for gluing linings and soles.

Types by composition

Reliability, degree of adhesion and other characteristics are determined by the composition of the adhesive. According to this parameter, 7 types of such products are distinguished.

PVC

These products include:

- polymers;

- benzene;

- acetone;

- tetrahydrofuran;

- PVC resins (provide resistance to environmental influences).

PVC glue is characterized by increased elasticity and is used to repair leather shoes and fix textile parts.

Polyurethane

Polyurethane compounds provide increased bond strength. In this case, the resulting seam remains elastic. During drying, the size of this glue increases, so polyurethane compounds are not used to repair dense materials. These products are mainly used for the restoration of rubber soles.

Nairite

The composition of nairite has the following characteristics:

- raincoat;

- gel base;

- quickly sticks (within three hours);

- withstands temperatures up to +75 degrees;

- tolerates extreme temperatures.

Nairite glue is used to fix zippers, insoles and soles.

Polychloroprene

This option is considered the most affordable.However, polychloroprene formulations also provide reliable adhesion.

Perchlorovinyl rubber

This composition is used for auxiliary work. But in some cases, this type of glue is allowed to be used for connecting dermantine and rubber soles. It is forbidden to process materials exposed to low temperatures and humidity.

Universal

Universal compounds (superglue) are used for minor repairs. These products are characterized by a high degree of adhesion and give quick results. However, the resulting seams are inelastic. Therefore, the connection is prematurely destroyed.

Epoxy

Epoxy adhesive is characterized by the increased reliability provided by polyamines. The latter are resistant to alkalis and a number of acids. Epoxy is also a way to create a strong bond with metals.

Review of the Best Work Shoe Compounds

The footwear compositions presented below correspond to the given characteristics, which correspond to a reliable adhesive.

Contact

This product belongs to a universal type and is used to repair shoes and other products. Contact provides reliable, but not long-lasting, material adhesion.

Eva

Another Russian product of a universal type, which is distinguished by moisture resistance properties.

Second

It is also a versatile superglue designed specifically for shoe repair. The second provides reliable adhesion that is not afraid of exposure to moisture and alkalis.

marathon of the moment

This superglue is considered the most popular in Russia. Moment is characterized by increased moisture resistance and elasticity. But, like other products of this type, the adhesive does not provide long-lasting hold.

Doneal

Donedeal sealant allows you to repair products made from different materials. This glue can withstand extreme temperatures ranging from -45 to +105 degrees and provides a reliable connection.

Uhu Schuh & Leder

This product is characterized by a quick-drying composition, suitable for bonding hard and soft materials. This product is resistant to moisture and temperatures up to +125 degrees.

Desmocol

Russian shoe glue based on epoxy resins. These ensure reliable and long-term adhesion between different materials. Therefore, Desmokol is used to connect the sole with the rest of the shoe.

Narit 1

Nairit 1 is one of the best adhesives used for shoe repair. This product provides a durable, watertight connection with increased strength. Nairit 1 bonds fabric, rubber, leather and other materials.

Polyurethane sewing handle

Universal super glue with increased elasticity and reliability. The composition is moisture resistant, therefore it is suitable for repairing soles.

Kenda Farber Sar 30E

A high quality Italian product, with which various materials are refurbished. The shoes, after gluing with this compound, which is not afraid of humidity and cold, can be put on after 4 hours.

Glue 317

Universal glue 317 is designed for the repair of various products, including shoes. The composition gives quick, but not long-lasting results. The product is not afraid of high and low temperatures, humidity.

Shoemaker

The cobbler creates high-strength joints that are not afraid of humidity and high temperatures. However, when cold, the composition loses its original properties. Therefore, the cobbler is used to repair summer shoes.

high high

A versatile and relatively inexpensive adhesive that provides reliable adhesion.The tops have a pungent, unpleasant odor typical of other shoe compositions.

Choice criteria

Due to the fact that there is a wide range of adhesives on the market, it is necessary to determine the main criteria on which to base the choice of a suitable product.

Appointment

When choosing an adhesive, you need to take into account the purpose for which the product is purchased. If the composition is purchased for minor repairs, it is recommended to give preference to inexpensive means used to increase the reliability of the connection.

When you need to repair the sole, this will do epoxy adhesive or similar, not afraid of exposure to moisture.

Price

This parameter does not play a decisive role if it is necessary to restore leather products or if the sole of expensive shoes needs to be repaired.

Name

This parameter does not play a determining role either. The only thing recommended to pay attention to is the nature of consumer reviews describing the features of a particular product.

Maker

The brand of glue mainly influences the price of the product. At the same time, some lesser-known manufacturers produce inexpensive, but high-quality compounds that provide reliable adhesion.

Compound

The properties of the glue directly depend on this parameter. It is not recommended to take products containing aggressive components. This is true when leather shoes are repaired.

Storage rules

This parameter, like many previous ones, also does not play a determining role in the choice of glue.

Labor conditions

To choose the right glue, you need to decide on the purpose of using such a product. If the product is purchased for one-time repair, then preference should be given to products made in small tubes.

Drying speed

On average, it takes 12-24 hours for the adhesive to harden. Faster compounds in some cases provide a reliable connection. However, some expensive products will harden in 4 hours.

Strength

Consumer reviews help determine this parameter. It is impossible to immediately determine whether a particular adhesive is capable of providing a strong connection.

Additionally, it is important to consider that certain compounds are used to repair specific materials.

Security conditions

Safety conditions when working with shoe glue are the same for each similar product. When repairing, it is recommended to wear gloves, avoid contact with the skin, and regularly ventilate the room .

Examples of shoe repair

Shoemaking, provided that the glue is correctly chosen, does not cause particular difficulties.

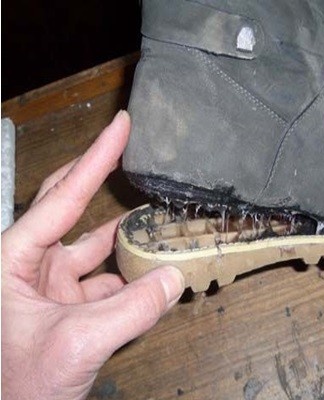

Glue the sole

To glue the sole you will need:

- Clean and dry shoes. If the sole has come off in several places, that part of the boot must be peeled off.

- Clean and degrease (with acetone, alcohol) the surface to be treated.

- Apply the adhesive to the surface according to the instructions given.

- Wait 2-3 minutes and press the sole firmly against the shoe.

- Leave the shoe well pressed for 10 hours or more.

To speed up the drying of the adhesive, you can point a hair dryer at the shoe.

Seal the hole

The hole should be cleaned of dirt and grease. If the hole size is large, the fiberglass mesh should be placed inside first. Then an adhesive composition (epoxy, polyurethane) is poured into the hole and a piece of building tape is put in place.

How to glue a sock

To glue the sock, this place is also smoothed and treated with sandpaper.Then a rubber or polyurethane patch is attached to the problem area and pressed for 10-12 hours.

How to do at home

To make shoe glue, you will need:

- casein (10 parts);

- borax (1 part);

- water (2 parts).

These components are mixed with each other until a homogeneous mass, after which another 2 parts of water are added to the resulting composition. This glue should be used within 2-3 hours.

Instead of borax, you can use ammonia, which is dripped into the casein powder until a gel-like mass forms. Formalin is then added to the latter, which increases the moisture resistance of the resulting glue.

Tips & Tricks

It is necessary to purchase glue, taking into account the type of material to be repaired. An unsuitable compound will create an inelastic bond that will crack quickly when walked on. In this case, repairs in a shoe store will be more expensive.

You can also use glue to make non-slip shoes. To do this, apply the composition in a thin layer on the sole, let it dry and rub with sandpaper.