Types of compositions you can glue together at home

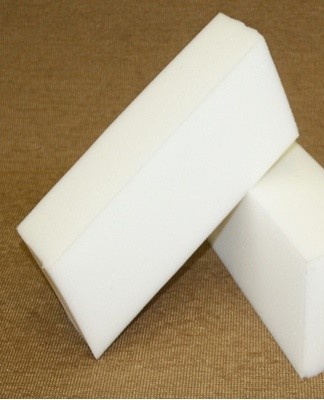

Polyfoam is used for insulation and decoration of premises. It's good material, not too expensive. It's easy to work with him. But there are certain points which will baffle the ignorant person. One of them is how to glue the foam sheets together. Expanded polystyrene is obtained from polystyrene by gas filling. Polystyrene is a chemically produced polymer. These substances have requirements for connection components.

Basic Adhesive Requirements

Before proceeding to the bonding of the foam, it is worth understanding the features of the choice of adhesives. General requirements:

- Assess the requirements of the finished work: under what conditions it will be used, how long the service life is calculated, etc.

- What will be the place of bonding: surface, adhesion, materials to be bonded.

- Bonding process: working time, curing time and temperature.

The choice of foam bonding materials is quite wide. The answers to the questions above will allow you to choose the appropriate option.

Varieties

Parts of expanded polystyrene are glued with various adhesives. These include:

- powder glue;

- polyurethane foam;

- polyurethane glue;

- liquid Nails;

- aerosol formulations;

- special mixtures;

- bituminous glue;

- hot melt glue.

Each of the adhesives has advantages and disadvantages. The choice depends on the objectives.

glue powder

Powder adhesives are sold in large bags. They require dilution with water. The proportions are indicated on the packaging. The bonding quality is high. Reliability leaves no doubt. Powder glue is good for large areas. This is the most affordable option for a complete renovation in an apartment. For bonding small areas, it is unprofitable due to high sales volumes.

Polyurethane foam

Polyurethane foam is used as the bonding compound. It has a reliable adhesive seal and excellent adhesion to the surface. Sold at any hardware store. Defaults:

- Speed of work - the foam hardens quickly.

- Expands upon solidification - the threat of deformation of expanded polystyrene.

- It deforms unevenly - the threat of the formation of voids that reduce the quality of the final product.

- High material consumption.

Conclusion: it is worth gluing the foam with polyurethane foam only when the coverage area is small.

Polyurethane adhesive

It is the ideal. Adhesives marked "For expanded polystyrene" are on sale. This glue glues both horizontal and vertical supports. It has a number of advantages:

- minimum consumption;

- the connection speed is high;

- convenient to use;

- well tolerates humidity and low temperatures.

Provides reliable connection of all materials with foam.Sold in ready-to-use cylinders. Spray polyurethane and polyurethane foam are most commonly used for bonding foam.

Liquid Nails

Liquid nails are gaining popularity. They provide:

- timeliness of work;

- optimal adhesion to the surface;

- solidification rate;

- length of service.

The adhesive is expensive. It is best used in small areas.

AVP

Glue is cheap. You can buy it in stationery stores and even in a regular supermarket. The composition quickly fills the voids in the wall, but does not provide the strength of the connection. For large volumes in construction and finishing works, it is better not to use it. But it is good to use for crafting.

Aerosol formulas

The spray adhesive is fast setting. It should be used in small areas. The composition is easy to use - it is sprayed on the surface of two objects, which are then pressed against each other. For lasting adhesion, 30 minutes is enough. The fastening is reliable and durable.

Special mixtures

Special glue for expanded polystyrene is the best solution to the problem. The substances included in its composition do not deform the structure, ensure the accuracy of the seam and the strength of the connection. Special adhesive mixtures designed for bonding foam plastic are economical. It is convenient to work with them. The installation is done quickly. The choice of special mixtures is quite wide.

Bituminous glue

Bituminous glue is used to reinforce insulation and facing materials. Bituminous glue is a wide range of adhesives based on bitumen with various additives. It is used in the form of hot and cold sealants. Cold sealants are used for interior work. Special components are added to cold mixes for bonding various materials.Bituminous glue for expanded polystyrene provides reliable bonding and waterproofing of joints. Sold in different weights. Most often used for outdoor use.

hot glue

Hot melt glue is popular with users for its versatility. Thermoplastic glue has unique properties:

- strength;

- rapid polymerization;

- neutrality at extreme temperatures;

- lack of smell;

- hypoallergenic;

- duration of operation;

- at low price.

Glue is widely used when you need to quickly connect decent volumes. The adhesive is sold as:

- rods,

- pellets,

- pillows,

- cylinders.

An excellent bonding material for small finishing jobs.

How to calculate the expense

All manufacturers indicate the approximate calculation of glue on the package. It indicates the quantity per square meter of the glued surface. Multiplying this number by the area gives the amount of glue. You always have to buy material with a small addition. If the styrofoam is stuck to the styrofoam, that's one thing. It is completely different when polystyrene foam has to be combined with different materials. It is impossible to take everything into account here. A supply of glue will help avoid trouble.

What cannot be used for crafting

Craft glue should have a number of qualities. The main ones are: the absence of toxicity and hypoallergenicity. Information on the composition of the adhesive is indicated on the packaging. Before choosing a glue for crafts, you should carefully read the instructions. If the glue contains toxic substances that can cause chemical burns or allergic reactions, you cannot use the glue for crafts.

How to stick to other materials

This question plagues many home craftsmen. Styrofoam is more likely to stick to other materials than to itself. Don't worry. Manufacturers have also taken this important point into account.

Concrete

Most often, concrete walls are insulated with foam. Dry adhesive mixes are used to join these two materials. The old putty is removed from the wall, if necessary, refill putty. Cover with earth.The mixture is diluted with water using a construction mixer. If there are shallow depressions on the wall, cover the foam with a continuous layer of glue. If the defects are larger, the adhesive should be applied in strips. The foam, smeared with glue, is pressed against the wall. The remaining glue is removed with a spatula.

Metal

Almost all adhesives are used to bond metal to foam:

- polymer dry mixes;

- silicone glue;

- aerosols;

- polyurethane foam.

The peculiarity is that instead of soil, a hessian substrate is used. Glue it first, then lay the foam on it.

Textile

It is not difficult to connect the fabric with the foam. For this purpose, any glue that does not leave stains on the surface of the fabric is suitable: aerosol, silicone, PVA. You can also use Moment-Crystal glue. It is transparent, does not leave traces and is flexible. Another simple way is to moisten the foam with acetone. Then put a cloth on it and roll it with a roller.

Glass

For gluing polystyrene foam to glass, it is best to use bituminous glass glue. It contains bitumen, clay and water. This composition allows good adhesion of the glass to other materials.

If the foam sticks in small amounts, it's best to use a spray or all-purpose adhesive.

Paper

It is often necessary to glue foam to paper when crafting. In construction work, polystyrene foam is glued to drywall. Home craftsmen advise using PVA glue or wallpaper glue for vinyl wallpaper to connect the paper to the foam.

TREE

Most often, polystyrene is glued to boards, plywood, linings, OSB panels. Connect it in different ways:

- polyurethane foam;

- assembly nails;

- adhesives.

Adhesives allow you to quickly connect polystyrene foam to wood. Most often, cement mortar is used, adding glue to it. It is moisture resistant and neutral to extreme temperatures.

How to do

You can make your own polystyrene adhesive. This will require 6 parts modified epoxy and 4 parts hardener. Everything is sold in hardware stores. The ingredients are combined and mixed carefully. A very strong adhesive is obtained. It has only one drawback: you can't do much with your own hands. Epoxy based adhesive is best used for small areas.

Tips & Tricks

People who want to combine polystyrene with other materials at home should follow the algorithm of actions:

- Before use, carefully study the instructions for use and strictly follow them.

- Before gluing, the surface of the foam board is cleaned of dust and dirt. This is done with a dry cloth. Residual foreign matter on the surface will adversely affect the connection.

- In order for the foam to adhere better to the surface, the glue is applied to the entire surface of the board.It is applied using a spray, a brush or a spatula. If strong adhesion is not required, then it is permissible to apply the adhesive in drops or strips. This can be done with a notched trowel or by pressing the mass through the ball.

- After connecting the surfaces to be glued, they are pressed against each other. Depending on the adhesive used, the craftsman has 1 to 2 minutes to assemble the parts.

- After attaching the foam board to the desired surface, remove the remaining adhesive with a spatula or dry cloth.

- Fixing time depends on the chosen composition.

Polyfoam is fragile. Care should be taken when working with it. Experts recommend treating the surface of the foam before gluing with an alkyd varnish. Due to the treatment, the surface will lose its porosity. This will allow you to reliably connect polystyrene foam with any material, even the simplest glue. By following the recommendations and paying special attention to the work, each home craftsman will be able to finish or decorate the house with foam.