Features and color palette of metallic paints and how to apply them correctly

It is customary to use metallic paint to paint various materials and give them a special shine. Metallic shades are applied to cars, special equipment or household appliances to achieve a unique design. In recent years, metallic reflections have been sought after for decoration and renovation work. The metallic shine is achieved using special additives for synthetic-based paints.

Features of the composition and principle of operation of metallic paint

The metallic luster of the paint is obtained by adding specific components. Composition of the metallic paint:

- Pigment. It is a crushed powder. It allows you to create shade.

- Pack. A component that provides a strong bond between the compound and the surface.

- Solvent. A substance that is responsible for the viscosity, the viscosity of the paint. For metallic paint, a viscous consistency is important.

- Aluminum powder. A crumb of aluminum that gives a metallic shine. The particles reflect light to create a silver metallic sheen.

The difference between acrylic paints, glossy matte type car enamels and metallic shades is in the peculiarities of the composition.

| Criteria | Metallic | Non-metallic |

| Features | The presence of aluminum powder | Different formulations based on synthetics |

| Fading Tendency | not inclined | Tend to |

| Application method | Difficulty creating an even layer | Whatever sort of |

| Price | High | Different |

| Special qualities | Protects against heat thanks to its ability to reflect light |

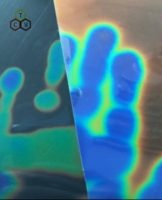

The mechanism of action of metallic is based on the reflection of light. A crumb of aluminum is an analogue of microscopic particles that create a specular reflection effect. The aluminum crumb is in the zone of action of the coloring pigment, it binds to the pigment for further reflection of light.

Advantages and disadvantages

When choosing paint to coat a car, owners often choose between automotive enamel and metallic paint. Auto enamel is created on the basis of alkyd resin, it creates a durable glossy coating, but cannot provide the effect obtained by applying metal.

Benefits of using metallic paint:

- metallic prevents overheating, as it has the ability to reflect light;

- the paint has improved properties to protect against mechanical damage;

- reduced susceptibility to rust due to the presence of aluminum shavings in the composition;

- does not need additional varnish;

- creates overflows.

The downside or difficulty of working with a metallic tint is the need to create an even layer.Any inaccuracies that auto enamel may hide will be noticeable in the metal finish due to the nature of the composition.

Color pallet

The all-metal color palette is varied. Among the classic shades, motorists choose silver, silver-black, metallic white. Unusual shades are considered red halftones: silvery light orange, silvery bright red, golden red. These shades are designated by the names: “apricot”, “accord”, “coriander”, respectively.

The color palette allows you to create different shades:

- white tone creates a pearlescent shine effect;

- metallic black provides a rich, even finish;

- bright colors with a metallic sheen appear muted.

How to paint correctly

The metal coating has its own peculiarities. The processing condition is the creation of a uniform finish. Unlike car enamels, the metallic is applied in 2 coats with a third coat for setting and leveling.

Surface preparation

Surface preparation becomes an important step. The result of the work depends on the correctness of this step. The preparation consists of several sequential steps:

- Removal of the old coating. Removal is carried out using tools with which you can pick up the cover and remove large pieces of material.

- Cleaning dirt, dust. Using improvised tools, pieces of the old layer are separated from the surface, dirt and mold layers are removed.

- Putty of chips, cracks, defects. Bare cracks are filled with putty, then made with a spatula to level.

- Sanding with sandpaper. Notches and small defects in the coating are cleaned with fine-grained emery paper.

- Degreasing. The body is covered with a degreaser, then wiped with a damp cloth.

- Primer.The surface is primed to create an even coverage area. Suitable primers are good quality primers in neutral tones. Apply 2 or 3 coats of primer with a spatula, then level.

The preparatory phase lasts several days. It is necessary to wait until the putty and the primer are completely dry to proceed to the next step. Puttying, or filler, is necessary when the material is badly worn. The thickness of the mastic layer is 2 or 3 millimeters. A thick layer of sealant causes the formation of cracks under heavy load on the vehicle during operation.

Experts admit the application of 2 layers of mastic. The first is applied with a wide spatula, causing the scratch or crack to be completely filled. The second layer is leveling. The third stage of putty is surface sanding. To do this, use a grinder, plane, sandpaper.

As a primer, two-component formulations are used, which include ethanol. Ethanol-based primer takes 60 minutes to dry. The choice of primer determines the quality of the main paint coat, since in most cases the elements of the main application and the primer are mixed together. Adhesion occurs due to the interaction of moving particles of ethanol and aluminum powder.

Paint application

The best application is to spray paint from an aerosol can. Another way is to use a spray gun or paint gun with low pressure created inside the fixture. The recommended diameter of the spray gun nozzle is 1.3 or 1.4 millimeters. This diameter allows you to create a layer of optimal width.To create the smoothest possible finish, it is necessary to take into account some of the characteristics of the paint:

- the base should not be too wet or dry;

- a thick layer should be avoided, otherwise it will remain liquid;

- a thick layer will not create a good mirror effect because the aluminum particles will sink and lose their reflective properties.

The method of application includes consideration of the hiding power of the base coat. The classic application scheme: 2 and 1. This means that to create a finish, 2 coats of paint and 1 coat of leveling type are needed:

- 1st coating layer;

- The 2nd coating layer is more humid;

- 3rd layer, correction, drip layer.

At the first stage, the creation of irregularities is allowed. The second coating is able to rectify the situation. The third application completes the process, eliminates any burrs, removes excess thickness.

Completion

The final stage is varnishing. Clear varnish will give the finish a special glossy effect. The metallic paint is varnished 10-15 minutes after the completion of the paint. The mistake of car manufacturers is the long waiting time for drying. This technique works with classic enamels, but is not suitable for metallic paints.

The mechanism of action is based on the fact that the metallic corrective layer absorbs varnish and creates a special rich finish. Varnishing is applied in 2-3 layers. Each of them must be completely dry. For the first application, the varnish is diluted with a solvent to a liquid consistency. Subsequent applications should be denser.

The varnish dries for 24 to 48 hours.During the drying period, the machine should be kept in a room with optimum air temperature, away from wind, dust and dirt.

Tips for Choosing Paint Colors

Choosing a color or shade of paint is complicated by the fact that when creating a metallic sheen, the selected color palette is different from the presented sample. When exposed to light, metallic paints look different; when lit, they change hue to deep, saturated tones. For this reason, it is difficult for owners to settle for just one shade of automotive paint. It is advisable to choose a cover, focusing on the basic rules:

- Ostensibly. This option is common. The owners apply a probe to the body of the machine and try to create a predictable image.

- By code, body number. This option is suitable for used vehicles. This is how you can find the original body color, remove the old upholstery and choose the right color scheme.

- By program. Modern technologies make it possible to create an image of the result on a computer. The application is able to select shades, depth, saturation.

Dark colors are considered as simple as possible, the difficulty is to enter a color with light shades. When using light metals, it is recommended to paint cars and other equipment with a transition effect in order to eliminate the shift in the thickness of the layers.

Spectrophotometers are used to check if the color is on or off. An indicator of 0 to 2 units indicates a full hit. An indicator from 2 to 5 is considered acceptable when repainting.An indicator above 5 units means a complete absence of color in the base coat. In this case, car painters are advised to repaint.