Types and descriptions of adhesives for aluminum, rules for use at home

Aluminum is considered a popular material due to its high strength and resistance to external factors. At the same time, the substance does not have high adhesive characteristics. This is due to the presence of a film on the surface. In order to achieve reliable fastening, special attention should be paid to the choice of glue for aluminum. Moreover, many effective formulations are on sale today.

Features of working with aluminum

Aluminum is considered one of the most popular metals. It is characterized by excellent strength and resistance to external factors. However, metal cannot boast of good adhesion. Therefore, it must be welded or glued.The use of glue is considered a popular method of fixing the material. A regular substance will not help you achieve good results. The aluminum adhesive must contain acids. They break down the oxide film and increase the adhesive characteristics.

Special adhesives help achieve a secure hold.Very often, a heat-resistant glue is used that can withstand the action of high temperatures.

What compositions will help you

Aluminum can be fixed in different ways. They can be made from resin or polymers.

resin based

Today on sale there are many means for fastening aluminum elements, made on the basis of resin.

mastix

This compound helps bond the aluminum and restore various connections. Fixed elements are even able to withstand the effects of low temperatures. The product can be used on wet surfaces. The substance helps to quickly and reliably fix the elements.

The product is considered heat resistant. Therefore, glued products can be used in different temperature conditions - from -55 to +145 degrees.

Cosmopur 819

This substance is a polyurethane solution. It creates a slimy seam between the parts. The tool helps fill in the gaps. Also, with its help, it is allowed to glue the corners. The composition can be used for fixing structural and other elements.

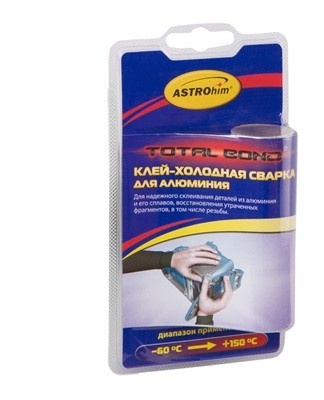

Astrohim ACE-9305

The tool helps to cope with various breakdowns. Its use allows to obtain a high resistance of aluminum parts or alloys. The composition is able to withstand a wide temperature range. Cold welding with this tool helps to restore broken elements - for example, wires.

epoxy metal moment

It is one of the most popular blends and two component formulation. The adhesive provides a secure bond to aluminum and other metals. In addition, with the help of a substance, it is possible to fix metal elements on glass, marble and many other materials. The composition helps to cope with cracks.

Abro steel

This tool is considered a universal composition. It can be used to repair household equipment. The adhesive is suitable for fixing liquid reservoirs. This provides an excellent seal. The composition helps to fix metal, ceramic and wooden elements. Also, the tool fixes products of different types.

The adhesive is characterized by increased sensitivity to the cleanliness of the parts to be fixed. If stored improperly, the substance will lose its characteristics.

Permatex cold welding

It is a two-component heat-resistant agent based on epoxy resin. It solidifies quickly and is flame retardant. The substance helps to bond various materials together, including aluminum. The composition is polymerized in a quarter of an hour. At the same time, it is able to withstand prolonged heating up to +149 degrees. The formed seam is very strong.

Titanium

This inexpensive product is characterized by high resistance to various mechanical loads. This is why glue is so popular with many crafters.

Wurth liquid metal

This cyanoacrylate agent is produced by a German company. It is considered the best solution for fixing metal surfaces of various elements. The composition solidifies quickly. Therefore, it is permissible to use it for quick repairs. The result is an inconspicuous seam. Thanks to this, it is possible to fasten not only metal. It is an excellent adhesive for transparent materials.

Cosmo PU-200

It is a two-component, high-strength product that has a polyurethane base and does not contain solvents. The composition has excellent heat resistance parameters. It is able to withstand the influence of external factors. After complete hardening, the joint can be painted.

The composition is used for fixing fiberboard of plaster, wood, aluminum, laminate. With its help, it is possible to restore and fill assembly joints. In addition, their width should not exceed 0.8 centimeters.

Polyurethane blends

There are many effective polyurethane formulations on the market today. They all differ in composition and properties.

Monocomponent

These products are made on the basis of polyurethane. They are solvent free. These substances are used on the exposed parts, which are first moistened with water. As a result, the substance reacts with the wet surface. As a result, the glue becomes hard. It helps to get a firm grip.

2 components

In addition to the polymer, the composition contains a hardener. These products do not require the use of water. As a rule, these substances are used indoors. These types of adhesives are resistant to the influence of oils, fungal microorganisms and mold. They are also considered to be very heat resistant and very elastic.

cold welding

Two-component substances, consisting of epoxy resin and steel powder, act as an adhesive. The product can be made in the form of a liquid or a putty.

The use of modern technologies involves the addition of various additives to the composition. With their help, it is possible to increase adhesion and resistance to aggressive factors. In addition, these components increase the operating temperature range. Sometimes these adhesives have a higher resistance than the metallic elements to be bonded.

General work rules

It is quite easy to fix aluminum parts with glue. In this case, it is recommended to adhere to the basic recommendations.

Surface preparation

It is recommended to carry out all manipulations with glue in a well-ventilated place. It is recommended to wear gloves and a respirator during this operation.

Adhesives often contain hazardous ingredients that can irritate the eyes and respiratory system.

Before sanding the surfaces with sandpaper, it is worth cleaning them from dust, grease stains and dirt. This can be done with a hard brush or brush. To prepare the surfaces to be fixed, proceed as follows:

- Remove fragments of rust and dirt.It is recommended to do this with sandpaper. It is recommended to use fine grits.

- Remove greasy stains from the surface. To do this, it is worth treating it with acetone. If there is grease on the parts, the adhesion is reduced by 20%.

- Wait until the treated surface is dry.

Bonding

To glue aluminum parts, you must do the following:

- Combine the adhesive with the hardener. It is recommended to do this in a special container.

- Mix the substance until it is uniform. Apply the ready-made composition for 10-60 minutes. The exact time is indicated on the packaging.

- Treat 2 surfaces with glue. This is done with a dotted or thin strip. Then it is recommended to press the elements well. Do not strongly compress the fragments, as the mass of glue will be squeezed out.

- Excess glue should be removed with a dry cloth. It is also allowed to moisten it in water or use a solvent.

- Fix the parts until the composition hardens. It usually takes a quarter of an hour.

The setting period of the adhesive composition may differ - it all depends on the specific manufacturer.On average, the duration varies from 5 minutes to 1 hour.

How to stick well at home

In order for the use of glue to be successful, it is necessary to strictly adhere to the technology and take into account the materials that are planned to be fixed.

Aluminum with aluminum

Innovative technologies allow the cold fixing of aluminum elements. For this, it is worth using Mastix cold welding glue. It is recommended to clean the parts with sandpaper and treat with a degreaser. Then apply glue and press the elements together. Keep for a quarter of an hour until the composition acquires a solid consistency.

With stone

For fixing aluminum to stone surfaces, it is recommended to use a two-component compound. To do this, squeeze the epoxy and hardener into a separate container and mix thoroughly. Apply to surfaces with a brush and press.

With porcelain

To bond porcelain, you must use an effective epoxy resin product. It is applied with a brush. It takes half an hour to harden the glue.

with a tree

Aluminum can also be attached to wooden elements. For this, two-component substances are usually used. Before fixing, it is worth sanding the parts with sandpaper.

With plastic

It is often necessary to attach aluminum parts to plastic. To obtain good results, the surfaces are degreased.

Other materials

This is not a complete list of materials that can be attached to aluminum elements. To get good results, you need to choose the right adhesive. Information about the materials that can be bonded can be found on the packaging.

Additional tips and tricks

To properly glue the parts, you must follow these rules:

- the aluminum elements are well fixed by a two-component epoxy adhesive;

- for aluminum it is worth using only special compositions containing acids and alkalis;

- Epoxy products should not be used if the product comes into contact with water or food.

There are many varieties of aluminum adhesives today, each with distinct advantages.

To achieve excellent results in fixing this metal, it is worth choosing the right composition.