Description of high strength adhesives for rubber, which are better and more reliable

The high strength rubber adhesive is considered to be very effective. It is used quite often. In fact, the composition is considered natural rubber, which dissolves in a special substance. Before buying an adhesive, you should familiarize yourself with its main characteristics. Today there are many effective products on sale.

Rubber Material Properties

Rubber glue is a product based on rubber dissolved in special substances. As it hardens, the product retains its elasticity. Therefore, it is allowed to use it for fixing materials with different textures.

Additional components are often added to the composition that improve the characteristics of the adhesive:

- polymer resins;

- vulcanization components;

- plasticizers;

- seam-like components.

There are quick-drying substances on sale. The compositions are used for household and industrial purposes. A quality product fills even small holes and voids, penetrating all cracks and seams. Thanks to this, the product is firmly held together.

The characteristics of the rubber glue are as follows:

- excellent adhesion;

- high strength of seams;

- no destruction over a long operating period;

- resistance to temperature influences, the influence of chemicals and aggressive factors;

- seam flexibility;

- seamless consistency;

- lack of lively aroma.

Some formulations are considered heat resistant. They are able to withstand intense heat. All rubber adhesives are waterproof. They keep moisture out of the glued area.

Types of glue for rubber

Today, there are many rubber adhesives on sale that are very effective.

Glue 88 (CA, N)

These adhesives are often used in construction. They are used for laying finishing surfaces. Also, the compositions are often used in the automotive field - with their help rubber elements are fixed. The substances are used for the manufacture of furniture and footwear. The composition helps to glue rubber fragments or fix them on paper, wooden or metal surfaces.

Glue 4508

This product is very resistant to moisture. It is considered elastic and very sticky. The composition is used for the manufacture of textiles. They are glued to special combinations or rubberized materials. The tool perfectly glues the boats together. They are also allowed to attach other PVC products.

Rubber Moment

This substance is very resistant to moisture. It is considered tacky and offers elastic seams. The tool is used for the manufacture of textiles. It is used for the production of rubber articles. High elasticity allows the use of the composition when repairing boats, leather goods.

The composition is considered two-component. Therefore, he needs preparation for work. The glue burns well, so keep it away from sources of fire.

Grade A rubber adhesive

This substance is made from rubber. It helps to make rubber stick to paper or leather. The composition is often used to repair car inner tubes. The product is distinguished by its ease of use and excellent technical properties. It dries quickly and retains its characteristics for a long time.

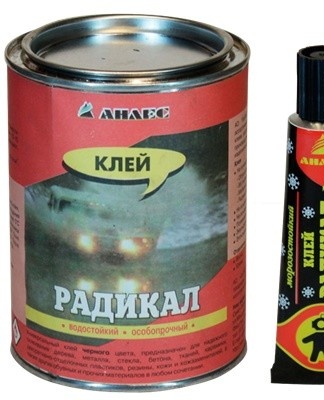

Radical

This adhesive is considered very durable and has good elasticity. The composition is able to withstand high pressure and severe stresses. The radical perfectly tolerates the influence of low temperatures and behaves well even in sea water. The adhesive is suitable for repairing kayaks. It is also used for bonding inflatable boats.

Core

It is an anaerobic agent that has a wide range of uses. It helps to get a firm grip on surfaces. The use of innovative technology makes it possible to actively use glue in industry and everyday life. It is often used in various repair shops.

High strength rubber adhesive composition

Rubber cement is based on natural rubber. Industrial and household complexes are on sale. They can have a liquid or viscous consistency. There are also two-component remedies. However, the base of each substance is considered dissolved rubber.

The following components can act as solvents:

- Chlorinated or aromatic hydrocarbons. The components are characterized by toxicity, therefore they are introduced into the glue in a minimum volume.

- Latex with water. This compound is characterized by low toxicity and low flammability. However, it does not adhere well to the base.

- Ethyl acetate with nefras. The chemical formula of the substance includes petroleum products and acetic acid ester.

- Resin with polystyrene. The substance makes the diaper durable. With a large amount of additives, the seam becomes less elastic.

- Plasticizers. Phthalates and lanolin can play their part. In addition, the glue contains mineral oils or carboxylic acids in the form of esters.

- Sulphur, metal oxides, amines. These components are responsible for vulcanization. The choice of additives depends on the properties of the rubber.

- Stabilizers. These ingredients help prevent the glue from turning into a gel. Usually diethylamine or ethanol are used.

Each manufacturer offers a unique rubber cement formula. It is developed according to the characteristics of the fixed surfaces.

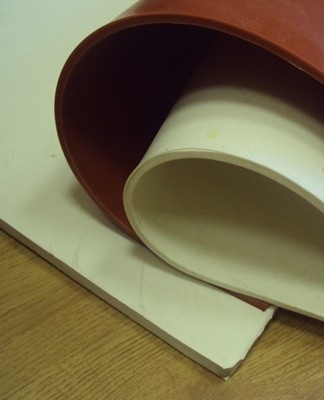

What can rubber be glued to?

Rubber can be bonded to various materials. To achieve a high-strength connection, it is worth choosing the right adhesive.

Metal

Sometimes you have to glue hard-to-fix materials. These include metal and rubber. Usually the adhesive does not freeze to smooth metal, but rolls. To bind such materials, TRS 4004, 103 88-NT, Leukonat, BF-2 substances are used.

To achieve reliable fixation of fragments, it is worth properly preparing the surfaces. First of all, it is recommended to clean the metal from rust or oils. After which it must be degreased. It is recommended to create a rough coating on the rubber and clean it with a degreasing agent.

Surfaces should dry, after which they should be covered with an adhesive and wait a quarter of an hour. Then apply the glue again and wait for the film to appear - it will take 10 minutes.

In conclusion, it is worth fixing the fragments and squeezing them with effort. If possible, it is recommended to warm the glued fragments and let them dry. The duration of this process depends on the composition.

PVC

To fix rubber with PVC, it is worth using glue 4508. This compound is very sticky and moisture resistant. It helps form an elastic seam and is often used in boat repairs.

Manual

To firmly glue a vacuum cleaner or other rubber product, you must follow the instructions for use of the substance.It is forbidden to use such a composition in rooms with a temperature below +5 degrees.

To increase the effectiveness of the fasteners, it is recommended to prepare the surface before applying the adhesive. To do this, they are cleaned of impurities - dust and dirt.

Before applying the composition to the surface, it is recommended to walk with an abrasive material. This increases the adhesion of the elements. To remove foreign bodies, use a soft, lint-free cloth. Degreasing agents such as acetone can be used to remove oil or grease stains.

It is worth applying the substance with a brush. If the mixture is very thick, it is recommended to use a spatula. Its shape and width are chosen individually. The thickness of the layer should be at least 2 millimeters. Usually it is selected taking into account the parts that are planned to be fixed. So, to fix rubber shoes or a spoon, 1 millimeter of glue is used. Gauze is laid on top, pressing it with a spatula. This layer acts as a reinforcing element.

After a quarter of an hour, it is recommended to apply a layer of glue again. To improve the connection, all elements should be placed under a press and left for a couple of hours. It is recommended to remove excess glue. Maximum bonding efficiency is achieved after 1-2 days.

Helpful Adhesive Tips

In order to glue a high-quality rubber product, one should adhere to the main recommendations of specialists:

- Individual substances become thick with prolonged storage. To avoid this, it is worth checking the expiration date before buying.

- Before fixing the elements, it is recommended to clean the surfaces from dust and dirt. The degreasing of the elements and a complete drying are not negligible.

- The adhesion characteristics of the material increase significantly if they are cleaned with emery paper before applying the composition.

- First, it is recommended to sand the surface and then degrease it. It is best to use a solvent that evaporates easily. This category includes gasoline and acetone.

- It is recommended to apply the substance with a brush. A spatula is suitable for thick masses.

- The thickness of the adhesive layer should be at least 2 millimeters.

- If stains or excessive amounts of glue appear on the surface of the product, it is recommended to remove it. This is done with a knife or spatula.

- It is recommended to keep the glued area under pressure for several hours.

Low humidity parameters lead to slower drying of the glue. A good composition sets in half an hour. Finally, it solidifies after 2 days.There are many effective rubber adhesives today.To achieve good results in fixing products, it is worth preparing the surfaces well and strictly following the instructions for applying the substance.