How and how to glue plywood with your own hands, types of compositions

There are several options for solving the problem of how plywood can be glued. However, when choosing an appropriate jointing compound, the type and scope of the construction material must be taken into account. So, for "rough" plywood you can use any type of glue, while for "finishing" - products that do not violate the texture and color of the boards. And for outdoor work, compositions that can withstand temperature extremes are used.

Main varieties

When choosing an adhesive for splicing plywood, it is necessary to take into account the requirements of such compositions:

- ease of use;

- viscous or semi-viscous consistency;

- rapid hardening;

- lack of volatile toxic substances in the composition;

- moisture resistance;

- the presence of antiseptic properties (not exposed to bacteria).

For plywood that is inside the premises, any formulation is used. For the connecting material used on the outside, synthetic glue is suitable, for moisture-resistant panels - based on urea resin.

Water or water-dispersive

Of these adhesives, PVA is the most popular. These products are based on toxic substances and components that give off unpleasant odors. The glue acquires sufficient strength within a day, but it takes 2-3 days to fully harden. Since the basis of PVA and other similar products is water, these products cannot be used to glue plywood sheets with a porous surface that absorbs moisture.

Carpenter

The basis of carpentry compositions consists of animal fats: casein and albumin. Both products are available as a dry mix, which must first be diluted with water. Albumin compounds are used for hot bonding, due to which the created seam gains strength faster.

Based on urea and phenol formaldehyde

Adhesives on this basis contain natural resins which are less toxic than epoxies. Compounds of this type are used exclusively for joining wooden products. Glue with such a base creates a seamless seam, therefore, such products are used to repair decorative elements.

Epoxy and polyurethane

Such formulations are based on solvents containing toxic substances and emitting a pungent odor. Therefore, it is recommended to work with such products in ventilated rooms or outdoors.

Epoxy adhesives are classified into one-component and two-component adhesives. The formulations of the first type are immediately ready for use. Two-component products consist of an adhesive and a solvent, which must be mixed before starting work. Such compounds are used for quick bonding of various materials, including wood.

How to choose the right composition

General requirements for adhesives have been given above. But when choosing the right product, you need to take into account a number of additional factors.Basically, when installing plywood, self-tapping screws and other fasteners are used. In cases where a laying of the material without a mannequin is carried out, it is recommended to use water or water-dispersing compositions. But these products do not tolerate contact with water. Therefore, PVA can be used exclusively indoors.

Epoxy glue is used for film faced plywood. But the latter, due to a special spray applied to the surface of the material, will not provide sufficient adhesion in this case. Therefore, the plywood surface is rubbed with sandpaper before splicing.

Also, when choosing an adhesive, it is necessary to take into account the manufacturer's recommendations on the scope of application of the composition.

popular brands

When choosing an adhesive composition for plywood, it is also recommended to pay attention to the brand of the manufacturer. The higher the demand for a product of a particular brand, the more likely it is that the purchased product will meet the above requirements.

Artelit

Polish brand specializing in the production of adhesives for gluing wooden products, including plywood and parquet. Artelit manufactures different types of similar products. The product line of this brand contains waterproof and quick-setting adhesives.

bostik

A French brand under which various construction products are produced. The Bostik company produces glues based on PVA, polyurethane and others.

"Rogneda"

A Russian brand specializing mainly in universal mixtures.Rogneda products are not inferior in quality to their foreign counterparts, but they are affordable.

Titebond

American company specializing in the production of flooring adhesives.

How to glue correctly

Although gluing plywood does not cause special difficulties, when performing such work, the following rules must be observed:

- before starting installation, it is recommended to clean the working surface from dust, dirt and grease;

- if the plywood is glued to the concrete on a water-dispersible composition, then the surface is pre-primed (including using glue);

- glue the material on epoxy resin in a ventilated place;

- do not use PVA glue outside the premises;

- after applying the aqueous composition to the surface, the plywood sheets should be temporarily fixed with self-tapping screws, since such adhesives freeze within 2-3 days.

As noted, laminate surfaces should be sanded with sandpaper before starting work. This helps to increase the level of adhesion of the material to the surface.

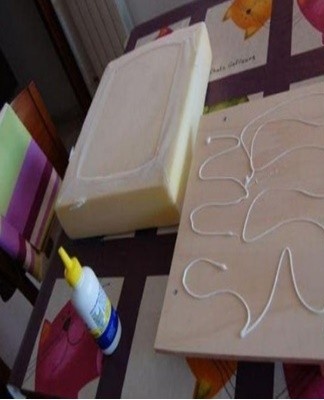

Paste sheets

To glue plywood sheets, you will need:

- Align the planes that will be glued together.

- Apply the adhesive to the work surface, following the enclosed instructions.

- After holding the required time (indicated in the instructions), bind the sheets together.

- Fix the plywood sheets with clamps and wait until the composition has completely solidified.

At the end of the work, you need to remove excess glue with a rag. If it is necessary to connect two thin sheets together, after the described manipulations, a veneer strip should be applied on both sides of the seam.

Splice

The plywood sheets are glued together at the joint and mustache. Applying the first fixing option, you should do the following:

- Align and sand the ends of the sheets.

- Degrease the work surface with alcohol or other similar solvents.

- Apply glue to the prepared surface and firmly press the sheets together.

- Apply glue to the joint to be created and lay the fiberglass of the desired size.

- Roll on the fiberglass.

- Wait until it is completely dry and remove excess material.

Tab gluing is performed according to the following algorithm:

- Place the plywood sheets on top of each other.

- Use a jointer to process the ends and form a mustache 12 times the thickness of a sheet of plywood.

- Grind each mustache with a grinder.

- Apply glue and press the fragments down.

- Pinch the leaves and wait for them to dry completely.

At the end of the described manipulations, it is recommended not only to remove excess glue, but also to grind the seam.

Alternative means

Tenons are often used to glue thick plywood. In this case, projections and recesses of the same shape and size are cut from the end of each sheet. Then glue is applied to these parts and the plywood is assembled.

This method allows you to get a stronger seam than described above. This is due to the fact that, thanks to the spikes, the contact surface of the materials increases.

Additional Recommendations

In addition to the recommendations described above for working with laminated and other materials, it should be borne in mind that to create a stronger connection, the glue with which the plywood is impregnated should be used. However, it is also necessary to pay attention to the purposes for which the leaves will be used in the future.