How to glue veneer at home, the choice of the best tools and installation technology

People are often interested in how to glue veneer. To be successful in this business, you must strictly follow the basic recommendations. First of all, you need to correctly select the composition of the procedure. To fix this type of coating, it is allowed to use a variety of substances. Strict compliance with the rules of application is not negligible.

The main types of veneer

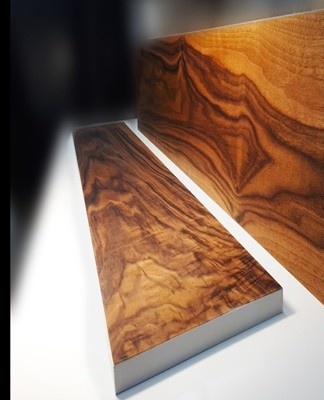

Veneer is a thin layer of wood. The substance is an absolutely natural material, which has several varieties:

- Standard - in oak, cherry, walnut. Other types of wood can also be used.

- Special - made from rare and valuable wood species.

- Cut roots of interesting species - this material is not suitable for the production of furniture, but it has an interesting texture. This category includes myrtle or eucalyptus.

- Exclusive - characterized by an unusual texture and non-standard sizes.

The material may also differ in the way of cutting and processing methods. Most often it is used in the furniture industry.Often the substance is glued to wall or facade panels. Veneer doors look real.This substance is characterized by its excellent appearance. It is allowed to be fixed on various wooden surfaces. In addition, the substance is distinguished by its affordable price. Therefore, it is often used to decorate the interior of living quarters. The main advantages of plating are:

- long period of operation;

- moisture resistance;

- respect the environment;

- high resistance.

By cutting method

Depending on the cutting method, the veneer can be radial and tangential. Each of the options has certain characteristics.

Tangential

This material is obtained by cutting the trunk parallel to the center. This helps achieve the effect of rings on the surface.

Radial

This is achieved by planing at 90 degrees to the tree rings.

By processing method

Depending on the method of processing, veneer has several varieties. Each of them has a number of features.

Shelled

This type of veneer is obtained by rotating the logs. During the procedure, a thin ribbon is cut from them. The saw of a special machine cuts the wood parallel to the grain. This material is obtained from oak and alder. Pine and birch are also used for its manufacture.

Saw

This veneer is made from conifers. These include cedar and Siberian fir. Due to this, it is possible to obtain boards with a thickness of up to 12 millimeters. Usually the material is used to make musical instruments. It is also sometimes used in the furniture industry. This type of veneer is considered the most valuable.

Planed

This material consists exclusively of solid wood.It can be obtained from oak or mahogany. It differs from other types of veneer in the method of cutting the wood. First, the trunk must be cut into bars. Then its layers are cut. This is done perpendicular to the fibers.

What glue can be used

To glue the veneer, you can use different types of adhesives. Each of them has certain advantages and disadvantages.

AVP

This type of glue is suitable for flat surfaces. In this case, the tight fastening method is used, which involves the use of a heated iron. PVA glue has many advantages. It does not contain harmful components and is therefore completely harmless to people. The composition is easy to apply and provides reliable fixation of wood.

Carpenter

Carpentry glue is very effective. Usually this substance is used to fix large elements.

Polyurethane

This composition provides a high degree of adhesion and allows you to reliably fix the veneer. To achieve good results, it is worth applying the composition correctly.

For wooden surfaces

To hold complex pieces together, it is worth using professional solutions designed for wood. Titebond is considered a common representative of this category. This one-component adhesive is very resistant to humidity. The composition provides good adhesion, withstands high temperature settings and solvents.

The product does not contain abrasives and does not damage cutting accessories.

Epoxy

Experts say it's perfectly acceptable to use epoxy to set the veneer. This substance is very effective and provides good adhesion.

How to stick at home

To achieve a strong and reliable fixation, the surface must be properly prepared, and the technology for applying the substance must be strictly observed.

Surface preparation

Attaching veneers is considered a simple process that requires strict adherence to instructions. Otherwise, the liner may come off. First, the surface must be carefully prepared. It should be borne in mind that the material is not glued to the untreated canvas.

To prepare a door or other product, it is recommended to proceed as follows:

- Remove the canvas from the hinges. This is done with a screwdriver or a lever.

- Place the product on the floor.

- Remove the fittings - decorative elements and handles.

- Remove the old coating with a sharp trowel. It is allowed to heat it with an iron or building hair dryer.

- Sand the coating with sandpaper or a special machine.

- Cover holes and flaws with a special putty, designed for wood.

- Apply wood glue.

How to prepare and cut the material

To perform the work, the required amount of material is required. Usually, veneer is sold by the meter. Purchased material must be cut. First, the rollers must be straightened to level the veneer. Thanks to this, it will take on a natural form.

To speed up smoothing, you can moisten the sheets with a sponge, place them between plasterboard or plywood sheets.

It is recommended to carefully measure the canvas. After that, it is allowed to cut it. There must be 5 centimeters of margin on each side. This will avoid problems with incorrect measurements. Use a plywood knife or plunge saw to cut the material. The use of a professional power tool is recommended. This will help you get precise and beautiful cuts. You cannot use scissors.They will lead to the formation of cracks in the material. It is recommended to choose veneer in the form of planks or stripes by pattern. After that, you need to glue the leaves with glue. This is done along perpendicular lines and joints.

Bonding methods

When using a two-component adhesive, mix the ingredients together. You can then engage optimally.

Cold contact method

It is quite a complicated method. To perform the procedure, you need a contact adhesive designed for veneers. This product is characterized by a minimum dwell time, which allows the glue to set quickly. This method is not suitable for inexperienced craftsmen, since it does not allow correcting errors in the work.

After applying the substance to the substrate, press the veneer well. This is especially important in the first few seconds. This avoids subsequent use of the press. Usually this method is used for gluing products of small sizes.

hot glue

It's an easier way. First, both surfaces are treated with a layer of glue, which should dry in a quarter of an hour. Then the veneer is applied to the main sheet and ironed with a hot iron. It is also permitted to use a lapping hammer.

The device helps to heat the adhesive layer. As a result, it melts and provides secure fixation of the veneer and the base. In addition, all air bubbles are released during the procedure. This helps to increase the quality of the hitch. This method requires thick glue. If the surface dries too quickly, the base should be lightly sprinkled with water. Large bumps are gently punctured or incised. Then they need to be ironed again.

Bonding by cold pressing

For this type of procedure, it is worth using Titebond adhesive. They need to process both surfaces and level them with a spatula. After that, it is recommended to fix the veneer to the base. Then carefully adjust the position of the material and secure it with a clamp.Fasteners should remain until the adhesive is completely dry. After that, they must be removed and the reliability of the fixation assessed.

Recommended adhesive brands

To paste a veneer into a part, you must use the following tools:

- PVA - used to fix flat surfaces.

- Titebond is considered a highly moisture resistant professional mortar.

- Epoxy resin - used for bonding thin wood and plywood.

Common Mistakes

When fixing the veneer, inexperienced craftsmen make the following mistakes:

- choosing the wrong adhesive;

- violating substance use technique;

- surface preparation for fastening is neglected.

Additional tips and tricks

To glue veneer to wood or MDF, you must follow these rules:

- prepare the canvas for work;

- when ironing the fabric with an iron, it must be covered with a layer of natural fabric;

- the iron must be driven continuously;

- when marks appear, they are removed with a sharp knife.

Veneer can be glued using different methods. With the correct choice of fixing compound, excellent adhesion to the coating will be achieved.