Reasons and what to do if the washing machine sucks water into the tank and immediately empties

When using the washing machine, problems periodically arise. A common situation is when the washing machine sucks in water and immediately drains it for some unknown reason. You can notice the malfunction by the noise of the fluid flowing down the drain and the lack of result after the end of the cycle.

Content

Main reasons

Faced with the malfunction of the equipment, you need to understand the causes of the breakdown. Further repair of the washing machine depends on the established reason.

Improper hose installation

If a malfunction is detected when trying to perform the first wash, this indicates a poor connection of the hose to the sewage system. By placing the drain hose under the tank, the liquid constantly flows into the drain.The internal structure of the machine signals a lack of water, and it is replenished, causing constant circulation.

The hose should be connected to the equipment above the tank. As a rule, it is attached to a siphon or a sewer pipe, leaving a rise of about 60 cm above ground level. Therefore, if the machine drains and tries to draw water at the same time, you need to check the location of the hose.

There are situations when it is not possible to check the point of connection of the pipe to the machine due to a protrusion on the wall, a screen on the bathroom and other restrictions. In such cases, to check, you need to turn on the machine in test mode and wait until the drum is filled with water. Then it remains to turn on the drain, while performing the task, press pause and monitor its level.

Blockage in the sewer system

The accumulation of debris in the drain becomes another reason why the washing machine immediately picks up and drains the liquid. The constant use of drains by all residents of houses periodically leads to the filling of the riser, the reduction of pressure in the pipes and the expulsion of water from the drum into the sewer.

If there is a problem, you can disconnect the drain hose and put it in the tub or sink while washing. This recommendation will help you to freely use the equipment until the problem is completely eliminated.

Valve malfunction

Washing machines are equipped with an inlet valve, which is designed to control the flow of liquid.A malfunction of the valve leads to the fact that it does not turn off the water, and in the event of a weakening of the membrane, liquid can leak out even when the valve is in the closed state.

Pressure switch failure

The washing machine pressure switch is responsible for regulating the level of liquid in the drum. After filling to the required level, the sensor sends a signal and the water flow stops. If the machine worked properly, and then began to drain the water immediately after dialing, the reason may be a breakdown of the pressure switch. A component fails in the following cases:

- oxidation or contact closure;

- violation of the tightness of the membrane;

- blockage or mechanical damage to the pressure tube.

It is not recommended to postpone the repair of a broken pressure switch, since a malfunction can lead to a number of negative consequences. In particular, the malfunction of the pressure switch causes the barrel to overflow and fluid leaks.

Electronic module failure

Improper performance of water collection and drainage tasks can be caused by a malfunction in the electronic module of the washing machine. If the equipment is equipped with a display, then in the event of a breakdown, an error code will be displayed on it, which will help to more easily understand the causes of the problem. Faced with an electronic failure, it is recommended to turn the equipment off and on again as a first step. If this does not solve the problem, it is better to seek help from specialists, since it is quite difficult to independently understand the operation of the electronic module.

Tank leak

Mechanical damage, due to the appearance of cracks on the tank, causes leaks. In many machines, the tanks are made of plastic, so their reliability does not always provide adequate protection.Damage can occur as a result of external influence or if various objects accidentally fall into the tank.

If the machine floods the floor due to a cracked tank, you will have to replace it, because removing the crack with waterproof glue will only help for a while.

How to correctly diagnose a machine failure

Comprehensive diagnostics help to establish the exact malfunction of the washing machine. The most convenient option is to check the error code displayed on the dashboard. If there is no display, you need to see how the machine works when washing.

If, when washing clothes, the equipment drains water immediately after dialing, you should check the correct connection of the hose, the condition of the sewage system and the operation of the main components.

How to properly connect to the sewer

For the correct operation of the washing machine, it is important to connect it correctly to the sewer. The connection method depends on the type of equipment, so the following points should be taken into account:

- If the machine is not equipped with a non-return valve that allows water to pass only in one direction, the appropriate height for the location of the drain hose is 50 cm.

- To eliminate the possibility of leakage, you should connect the drain hose to the sink above the knee. For this purpose, an additional siphon for waste water is required.

- By analogy with the connection via a siphon, you can connect a hose to the water drainage system of the bathtub. You must choose the appropriate option depending on the location of the machine and the location of communications.

- Regardless of the method of arranging the drain, the hose is attached to the rear wall of the washer, thus avoiding twists and kinks, so that water can constantly flow into the sewer.

- Drainage can be done directly into the sewer by installing a drain. It is recommended to use a rubber gasket for a secure connection.

How to remove a blockage in the sewers

The most effective way to remove blockages in sewers is through the use of chemicals. Modern substances contain acids or alkalis that dissolve the deposits accumulated in the pipes. To combat blockage, it is enough to pour the agent into the drain hole, add 0.5 liters of water and flush the drain with a large amount of liquid after 10-15 minutes.

Pressure switch repair

When a water intake and drainage problem arises due to a broken pressure switch, you need to fix it. The characteristics of restoring the working capacity of the part depend on the cause of the breakdown.

Oxidation of contacts

Contact oxidation can be eliminated by carefully opening the sensor and cleaning it. This procedure is best done only with experience. Otherwise, it will be easier to perform a complete sensor replacement.

Closure of contacts

With pressure on the membrane during washing, the contacts close and open, due to which a signal is sent to the control module about the water flow.

In case of malfunction of the contacts, it is recommended to replace them.

Membrane depressurization

The formation of cracks and other damage to the membrane leads to water leakage. If the faults are minor, you can repair them with a waterproof adhesive solution, but this method does not offer complete protection against water leaks. The optimal solution to the problem is to install a new membrane.

Clogged pressure tube

Disconnect the drain tube from the system to clear the drain if there is a blockage. Then cleaning agents are poured into the tube and rinsed with strong water pressure.

Replacement procedure

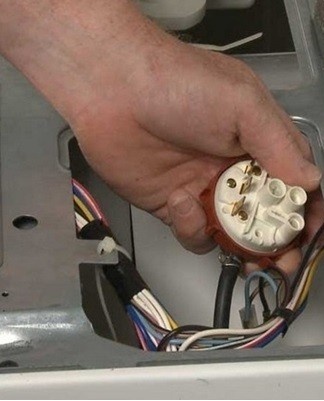

Install a new pressure switch according to the step-by-step instructions. This requires you to do the following:

- Disconnect the washing machine from the mains and turn off the water supply.

- Remove the top cover under which the pressure switch is located.

- Unscrew the clips, disconnect the wires from the pressure switch, remove the tube and remove the component.

- Reverse the procedure and place a new part.

How to repair a drain valve

To fix the drain valve, you need to get to it. First, disconnect the hose and unscrew the screws that hold the back of the machine. Then disconnect the terminals with wires and remove the drain pump. The filters are unscrewed from the filter and the pipe, after which you can start repairing the valve. If cracks are present, they are treated with waterproof glue, and in case of severe deformation, a complete replacement is required.

What to do in case of failure of the electronic module

You can check the status of the electronic module using diagnostics. In some models of Indesit washing machines and a number of other manufacturers there is an automatic test. If you find a breakdown, you should contact the service center, since repairs require special skills.

When to contact a specialist

It is recommended to use the services of specialists in case of serious damage to internal parts, when it is impossible to replace it yourself. It is also worth contacting professionals if you are not confident in your abilities.

Rules of operation

Compliance with the rules for using the washing machine reduces the risk of breakdowns. The main requirements for operation include correct installation, removal of transport bolts, checking that the tank is not overloaded.