Rules for installing do-it-yourself slopes on wooden windows and finishing methods

Wooden windows are an aesthetic and ecological solution that will decorate any home. In addition to the installation of windows, special attention should be paid to slopes. They should harmoniously fit into the surrounding interior without losing functionality. How to choose the right slopes for wooden windows and what you need to install them with your own hands, we will find out below.

Content

- 1 Varieties of slopes for a wooden house

- 2 How to choose the right finishing material

- 3 Preliminary works

- 4 Coating of interior slopes

- 5 How to plaster properly

- 6 Self-assembly rules

- 7 Warming up

- 8 Detailed instructions for installing wooden slopes

- 9 Common Mistakes

- 10 Rules and features of operation

- 11 Additional tips and tricks

Varieties of slopes for a wooden house

The construction market offers a wide range of materials from which slopes are made. Among them are:

- drink;

- Plastic;

- Lining;

- sandwich signs;

- drywall.

Each material has its own advantages and disadvantages, which should be discussed separately.

Drink

The best option, in harmony with the wooden frame of the building. When making wooden slopes, the following species are chosen:

- beech;

- cedar;

- Oak;

- larch.

Among budget options, pine can be distinguished, but it is not very suitable for exterior decoration due to its softness.

To note! Experienced builders, who have been installing wooden structures for several years, are advised to choose a material for the slopes identical to the window frame.

Plastic

It is considered a cheap substitute for wooden slopes that not every homeowner can afford. Today, no one is surprised by plastic windows in wooden buildings, because they are inexpensive and at the same time fit harmoniously into the overall concept of the building. Advantages of plastic slopes:

- low price;

- sustainability;

- strength;

- Easy to install and use.

Disadvantages:

- ordinary plastic looks cheap, which loses the overall appeal of the building.

Accompaniement

Another alternative to wooden slopes that goes well with log homes. The advantages of the material include:

- the price;

- pleasant appearance;

- ease of installation.

Unfortunately, the liner has many drawbacks that significantly reduce its appeal as a base material:

- requires additional processing in order to increase the protective properties;

- looks worse than wood;

- less durable than plastic.

Sandwich signs

A type of plastic that favorably differs from it in a set of features. Sandwich panel slopes have all the advantages of plastic models, without having their disadvantages. They look much better and the laminated film that covers most models greatly expands the design space to experiment with.

drywall

The benefits of using drywall in the slope fabrication process include:

- to install slopes, you do not need to prepare a special tool;

- drywall is cheaper than other materials;

- in the process of working with drywall, a minimum of waste remains;

- blends well with plastic and wood windows.

Disadvantages:

- a plasterboard structure has indicators of low strength;

- the material absorbs moisture well, which negatively affects its general condition;

- being under direct sunlight, drywall gradually deteriorates.

How to choose the right finishing material

Sandwich panels are chosen from budget options that have an optimal price-performance ratio. They have good durability, a wide variety of textures, and their prices do not bite, unlike wooden products. If you are ready to pay for the beauty and environmental friendliness of the material, buy wood of the species from which the window frame is made.

Preliminary works

Before proceeding with the installation of slopes, a number of preparatory steps should be taken:

- first of all, it is worth making sure of the reliability of the window frame. If it wobbles or has deviations in one direction, you must immediately correct the defect;

- we check with a tape measure the length and width of the window opening;

- we check the window frame for mechanical damage or factory defects.

If slopes are installed instead of the old interior parts, do not forget to dismantle them first, cleaning the place from excess construction foam and debris.

Coating of interior slopes

Facing the interior slopes, you will need:

- clean the work surface, removing the remains of construction debris and polyurethane foam;

- with the help of a putty, the cracks and unevenness of the floor are covered;

- we install the slats, which will serve as the basis for our fastening;

- correct the profile;

- we insulate the place under the slope;

- we insert the slopes into the profile and process the joints with a sealant.

To note! This method is best for working with sandwich panels or clapboards.

How to plaster properly

We create windows under slopes:

- we treat the working surface with a primer, with the help of which reliable adhesion of the plaster to the wall is ensured;

- a solution of liquid mastic is applied to the wall, which makes it possible to increase the quality of adhesion;

- we mount beacons on the solution, which will serve as guiding elements during installation;

- we put the ready-made solution on the slopes and put it in a plane, smoothing out the differences and irregularities;

- wait for the solution to dry a little, after which it is rubbed with sandpaper;

- remove the beacons, then fill in the holes left in their place;

- we rub the surface again.

Self-assembly rules

When self-installing slopes, a number of rules should be taken into account, which differ depending on the choice of fastening material.

It could be :

- polyurethane foam;

- frame made of bars.

On polyurethane foam

When installing window slopes on polyurethane foam, it is recommended to use one-component polyurethane foam. It dries quickly, which greatly facilitates the workflow. After the slope is installed on the wall or ceiling, it is necessary to maintain it for some time.

If you let go immediately, the materials will not have time to seize, and the work will have to be redone. The advantages are the low cost of installation.

On a frame of bars

A frame made of bars is used when the work surface has significant irregularities or additional space for insulation is required. Algorithm of actions:

- we fix the slats along the perimeter of the opening;

- we fill the space with insulation;

- we attach the facing material to the bars.

Fixing is done using:

- liquid nails;

- self-tapping screws with dowels;

- special fasteners for the lining.

Liquid Nails

Liquid nails, according to the principle of work, resemble polyurethane foam. They are also applied to the back of the slope, after which it is attached to the required base. Differences from foam are faster drying speed and economy.

Self-tapping screws with dowels

With their help it is convenient to fix wooden parts. Self-tapping screws are embedded in the slope, and the joint is closed with a decorative plug. This method is extremely convenient, in addition it allows you to fix the part in its place right away, which saves a lot of time.

Liner clips

They are mainly used for fixing the lining, as they allow you to securely fix a wooden product, while hiding the place of fixing itself.

To note! The above fastening options are applicable without the construction of a bar frame.

Warming up

An important part of the repair work associated with the installation of slopes is the insulation of the window frame. Of course, you can do without it, but in winter it will be much colder in an uninsulated room. Consider as insulation:

- polystyrene;

- penoplex;

- mineral wool.

polystyrene

Low cost insulation, highly demanded by consumers. It is easy to work with, it costs a penny, and in terms of the level of thermal insulation it does not differ much from other competitors.

Penoplex

An expensive analogue of polystyrene, which differs from the "younger brother" in its energy-saving properties. Among other advantages of the material are noted:

- denser structure;

- less tendency to absorb moisture.

Mineral wool

It is used in the case of thermal insulation of frame structures, since its laying is extremely convenient. When buying insulation material, pay attention to moisture resistance. For insulation, brands that are distinguished by a tendency to absorb excess liquid are not suitable.

Detailed instructions for installing wooden slopes

Installation of wooden slopes in a building is divided into the following stages:

- markup;

- frame installation;

- fine workmanship;

- facing joints with trays and decorative strips.

markup

Using a pencil or marker, mark the location of the mounting bar. The distance between the bars should not exceed 50 centimeters. This approach will keep the structure strong and prevent further deformation during operation.

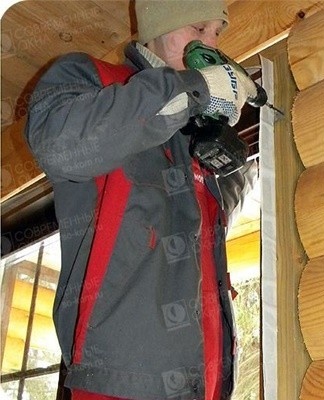

Installing the frame

We fix the mounting bar according to the markings, not forgetting to drill the holes for the dowels before that. If necessary, spacers are installed under the bars, with the help of which the worktop is leveled. It is important not to allow deviations in the countertops and to check the correct angles around the entire perimeter of the window.

Neat finish

Installation starts from the window frame. Not tightly fit the slope.Leave a space of at least 5 millimeters. First, the ceiling part is fixed, after which the side trim is installed. Leave gaps of 3 to 4 millimeters at the corner joints. They will be covered with decorative elements, and the siding will not deform over time.

Trays and decorative bands

Gaps left by builders for seasonal warping are closed with decorative strips. The interstices left between the opening of the window and the external slope are closed by trays. Fix the decorative elements with glue.

Common Mistakes

Many novice builders make a lot of mistakes during installation. Here is an example of the most common:

- an empty space is left under the slope, which is then blown away by the wind;

- the slope material, fixed from the inside of the room, does not interfere with the window profile;

- in the area of the window sill, gaps are left through which cold air from the street is blown.

Rules and features of operation

Periodically, the slopes are washed with a special solution for processing PVC, after which they are wiped with a dry cloth. The room needs airing from time to time in order to remove excess moisture from the window frame area.

Additional tips and tricks

Useful tips:

- when washing the window frame and slopes, do not use harsh chemicals;

- Do not forget to lubricate all window seals before the start of the winter season. Thus, the structure will last much longer, and you will not have to spend money on repairs and replacement of the window frame.