How to properly glue sound insulation in a car with your own hands, step by step instructions

People often wonder how to properly glue sound insulation in a car. To achieve the desired result, you need to familiarize yourself with the technology of the procedure in advance. In addition, beginners often make many mistakes. To obtain good results, it is recommended to choose the right materials for handling. Observance of the technique of the procedure is of no small importance.

Common Beginner Mistakes

Inexperienced craftsmen often make many mistakes when performing such a procedure. This prevents them from getting the results they want.

Choose a subcontractor

Errors when choosing a workshop lead to poor quality results and loss of money. Accordingly, the soundproofing effect cannot be obtained.

Planning errors

If the work is poorly planned, there is a risk of the following consequences:

- There is a high probability of wasting time and money.

- Often you have to travel multiple times to get tools and materials, as they will be in short supply.

- It may be necessary to rework the work.

- If you glue once and then remove the sound insulation, you cannot reuse it.

- The soundproofing process takes a lot of time and effort. It should be borne in mind that it will not be possible to perform the procedure in 1-2 hours. In such a situation, a sufficient amount of patience and perseverance will be required.

Bad choice of materials

Errors in the choice of material are quite common and lead to very unpleasant consequences. In this case, the following characteristics should be considered:

- Quality materials are quite expensive.

- The habit of saving creates the need for new expenses.

- Substandard materials begin to chip ahead of time, which leads to corrosion of the case. These materials have little effect. As a result, the soundproofing will not work.

- Poor quality materials are harmful to health. Because of them, the air in the cabin is poisoned with dangerous fumes.

Error in choosing the level of sound insulation

You should not choose the minimum level of sound insulation, because later you will have to use more expensive materials.

Workplace

Inexperienced craftsmen carry out soundproofing anywhere - on the street or by the roadside. It's extremely annoying. Moreover, the onset of night can catch such a master at the most inopportune moment. There is also a risk of theft of valuables.

Wrong tool selected

Choosing the wrong tool creates many problems.If you use only one screwdriver for the procedure, it will be very difficult to achieve good results. If you want to do a good job, you need the right tools.

What tools will you need

To achieve good results when soundproofing a car, it is worth preparing everything you need in advance.

screwdriver set

To perform the procedure, you will need a whole set of screwdrivers. It should include a Phillips and nut driver. Sometimes it is necessary to use an asterisk.

rolling roller

It is better to prepare several rolls at once. It is advisable to use tools of different sizes to level the coating.

boot knife

It is recommended to cut fragments of material with a sharp boot knife. This tool is considered the most convenient.

Scissors

For work, you should definitely prepare sharp and durable scissors.

Solvent

Using a solvent, it is possible to degrease the surfaces.

Construction site hair dryer

To warm up the coating, use a construction hair dryer. An ordinary household device is not suitable in this case.

rags

With the help of a cloth, it is possible to remove dirt from the treated surface.

putty knife

A soft spatula is suitable for soundproofing.

Roulette and ruler

These devices help to calculate the required volume of materials and perform the procedure as accurately as possible.

Materials choice

All substances for sound insulation are divided into 2 large categories - absorbing vibrations and absorbing sound. Both types of coatings should be used to achieve excellent results.

Vibration absorbing compounds are attached to the body parts.They help to dampen vibrations that appear due to the operation of the machine or small irregularities in the road when driving.

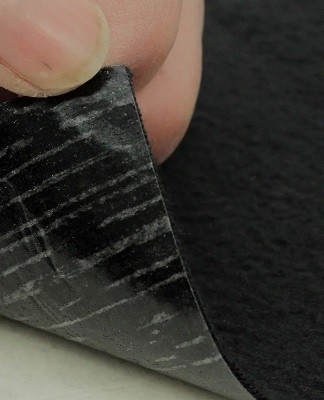

Vibroplast is considered a popular representative of this category of materials. The product is made from polymers. It has an aluminum coating. The substance is 1.5 or 2.3 millimeters thick. The more expensive options - Silver and Gold - have better vibration damping characteristics with the same thickness. Bimast self-adhesive anti-vibration insulation is characterized by a bituminous base. The coating can be paper, textile or aluminum.

Bitumen is considered the basis of vibration absorbing substances. It is also possible to use a putty with similar properties. Most new cars are already coated with vibration-dampening materials.

Sound absorbing compounds are attached to the vibration isolation. They are used to absorb noise from outside the vehicle. This type of material is characterized by a self-adhesive layer. These include Splen, Barrier, Vibroton sound insulation.

Bitoplast material, which is used as a gasket, is very popular. The tool helps to cope with squeaks between the plastic elements of the cabin.

The listed materials have a porous texture. Thanks to this, they are able to absorb sounds. Such coatings are made from polyurethane foam. Expanded polyethylene is also used for them. Substances are characterized by different thicknesses.

Using sound absorbing materials without applying vibration isolation will not provide the required results. The same goes for the demand for soundproofing construction sites.

The most effective way to reduce the noise level is considered to be the treatment with liquid soundproofing of car elements. Often, motorists try to carry out the procedure on their own. They spend a lot of time and money fixing the car, but they can't get the results they want. Moreover, this is observed even if a composition of good thickness is used.

This is usually caused by a lack of understanding of noise sources in the vehicle. The maximum percentage of these sounds is due to the vibration of the elements of the body, which is associated with a small thickness and high conductivity of sounds.

To eliminate such problems, it is recommended to stiffen the parts. Vibration-absorbing coatings help achieve this goal. They attach to parts and increase their thickness. The result is a whole.

The resulting vibration is damped by the part itself. This avoids spreading it on the body. Therefore, one of the most effective methods of reducing the noise level is considered to be the treatment with liquid soundproofing of car elements.

Aerosol cans with such compositions are especially convenient to use. They can be applied even in hard to reach places. This achieves maximum coverage.

Using a liquid substance on the exterior of the car makes the sound insulation of certain parts of the car more effective. In particular, such means contribute to improving the "noise" of car passages. The disadvantages of a liquid agent include a long drying time. It can take up to 2 weeks.

The use of porous sound insulation for the hood performs more thermal insulation functions.This is considered fully justified as it helps to make temperature fluctuations less sharp and less frequent. This will have a beneficial effect on the corrosion resistance of the elements.

Varieties

Today there are many types of materials on sale that are actively used for soundproofing a car. Thanks to this, each master will be able to choose the appropriate option.

Visomat

This product is made from resin covered with a layer of aluminum foil. The substance is suitable for gluing large surfaces. These include the roof, trunk, floor. The material is also suitable for arches.

vibproplast

It is an aluminum-based material made from bitumen. It is used to cover the hood and trunk. They can also be used to stick on the roof, doors, arches.

Missed

This material has a porous structure. It provides sound and heat insulation. The product is suitable for use in almost all problem parts of the car.

Biplastic

The substance is similar to foam rubber. It provides good insulation on windshield pillars or plastic parts. The substance can easily adapt to the shape of any space.

Magdalene

This is a special material covered with an adhesive layer. It is used to wrap wire harnesses used to fill gaps between items.

Brands and manufacturers

Various companies are engaged in the production of sound insulation products. This allows motorists to choose the products in terms of price and quality.

Money

This vibration absorbing material has a flexible and resilient texture. It is characterized by a self-adhesive foil base. On the surface there are marks in the form of squares measuring 5x5 centimeters.Thanks to this, it is possible to cut the sheet into fragments of the required size.

The substance does not absorb moisture and has anti-corrosion properties. The product acts as a sealant. It can be easily mounted on a surface that has a complex relief. The substance does not require heating during installation. Its weight is 3 kilograms per square meter. The material is 2 millimeters thick.

With this tool it is allowed to process the doors, side parts of the body and the roof. It is also used for the hood or trunk. The composition is suitable for application to the engine panel of the car interior.

Bi-Mast Bomb

It is a vibration absorption device, which is a multi-layered structure. It includes a surface layer based on aluminum foil, a sheet of bitumen composition and a rubber coating.

To fix the material to the surface of the car, it is recommended to heat it up to 40-50 degrees. This is done with a technical hair dryer. The material does not absorb moisture and has high efficiency. The substance is suitable for speaker audio preparation. Its thickness is 4.2 millimeters and its weight is 6 kilograms per square meter.

The substance should be used for application on the engine shield, the underside of the car, the drive shaft. Also, the material is used for the wheel arches and the area above the muffler.

Accent

This material is classified as sound absorbing. The substance includes a metallized film, an adhesive layer and a highly elastic polyurethane foam. The composition has excellent thermal insulation characteristics and is able to absorb 90% of noise.

The thickness of the material is 10 millimeters. Its weight is 0.5 kilograms per square meter. The effectiveness of the tool is in the range of 40 to 100 degrees.

The material is recommended for processing the trunk lid and hood. It is used for the engine compartment partition.

Bitoplast

This sound absorbing material can also be used as a gasket. With its help, it is possible to cope with squeaks and bouncing in the cabin. The product is made on the basis of polyurethane foam and has a sticky layer. It is protected by a specially impregnated gasket.

The material is considered durable and water resistant. It does not degrade and has excellent thermal insulation characteristics. The substance reaches 5 or 10 millimeters in thickness. Its weight is 0.4 kilograms per square meter.

Magdalene

It is a sealing material that is often used for decorative purposes. The coating is characterized by a black textile base, which has a thickness of 1 to 1.5 millimeters. It is distinguished by an adhesive layer. It is protected as a release liner.

The tool is suitable for eliminating gaps between the decorative fragments of the body and the interior. They also close holes in the dashboard and seal air ducts.

Shumoff

It is a self-adhesive seal made from expanded foam rubber. This material is characterized by high resistance to repeated loads. The tool is used for application on air ducts and joints of plastic panels.

PLS

All materials of the STP category have an adhesive layer that allows them to be glued to surfaces - horizontal or vertical. In addition, it is allowed to do it on the floor or the ceiling of the car. The procedure is very simple. To do this, it is enough to remove the protective film, glue the material and roll it up.

When choosing a coating, it should be borne in mind that vibration dampers of the Vibroplast category can be attached without the use of additional tools. Due to their excellent adhesion, their installation does not cause any difficulties.

Using shock absorbers from the Bimast category, you will not be able to do without a hair dryer. First you need to remove the protective film, turn it over and heat the adhesive layer with a hair dryer. Then glue the material and roll it well with a mounting roller.

Objective

Materials of this category are distinguished by high efficiency. They have excellent hold and ease of use.

Accent

In the role of thermal insulation, a special Accent 10 KS material is used. It helps keep the engine compartment warm in the winter. The substance is very resistant to high temperatures and does not ignite under the influence of high engine temperatures.

When choosing a material, it is worth taking into account the presence of factory thermal insulation in the car. It should not be thrown away. In this case, the additional sound insulation will be of an auxiliary nature.

Some vehicles do not have factory hood sound deadening. In this case, it is recommended to use a sufficiently thick material as a heat insulator. Its thickness should be 15 millimeters. In combination with vibration isolation, it will be possible to achieve maximum effect.

How to properly perform sound insulation with your own hands

To successfully perform sound insulation, it is worth considering the location of the procedure.

hood

It is recommended to use Vibroplast for gluing the bonnet. This substance is light. If you use a heavier material, there is a risk that the cover will become heavier. As a result, there is a risk of the bonnet dampers leaking.

To obtain a secure hold, the surface must be brushed and degreased. Also, the material should be pre-rolled with a roller.

To avoid errors when cutting parts for sound insulation, it is recommended to make cardboard templates. It is important that they match the surfaces in size and shape. In accordance with the templates, the parts are cut from a special material.

To achieve high-quality soundproofing of the hood, it is recommended to apply the material in several layers:

- The vibration absorbing material is glued into the first layer. It is important that it has increased thermal stability. A vibrating layer should be used to bond all surfaces between the stiffeners. It is forbidden to attach the material directly to the ribs, as this causes deformation of the cover.

- The second layer uses heat-insulating material.

- The third layer is to use the Shumka plant. However, Modelin is more efficient.

Doors

Car doors are glued to reduce outside noise. In addition, this procedure aims to improve the sound quality of music. Even the simplest soundproofing material gives excellent results.

If a minimal amount of procedure is planned, only one vibration damping material is needed. Vibroplast Silver or Gold is suitable for this purpose. It is recommended to fix the substance only from the inside of the door. This is done directly in front of the column.

It is important to treat the maximum area with vibration isolation material. The quality of the procedure depends on it. The weight of the material is not negligible. If the doors are overweight, they may sag. As a result, it will be necessary to replace the hinges.

Owners of a powerful audio system who want to improve its quality will not agree with a minimum dimensioning. In such a situation, an integrated approach will be necessary. In this case, it is worth applying at least 4 layers of material.

To do this, perform the following actions:

- It is recommended to glue the inside of the doors with the first coat. In such a situation, the material is fixed through special holes.

- The Vibroplast of the Silver and Gold series can again be applied. It is fixed behind the loudspeaker.

- The second layer on the vibration isolation material is laid Splen with a thickness of 4 millimeters. Accent is also suitable for this.

- Then you need to cover the doors with a layer of material from the outside. In this case, all technological openings should be completely sealed, and the door should be made almost airtight. When doing so, the drainage holes should be left open. This prevents the accumulation of condensation in the doors.

- Outside, glue the doors with Silver class Vibroplast. Splen or Accent is applied on top.

- The next step is to soundproof the door cards. This prevents the appearance of squeaks or other sounds. For this, a special Bitoplast material is used. In this area, the layer should be as thick as possible.

- The so-called crickets inside the doors, rods and handles are covered with Madeleine. This material prevents squeaks.

- It is recommended to treat the rear doors the same as the front doors. If there are no speakers, the hardware volume may be reduced. It is also allowed to use a more subtle product.

Roof

Soundproofing the roof of a car should be carried out to reduce rain noise, eliminate vibrations and crickets. After pasting the ceiling, the effect can be evaluated during the next rain. Even in a downpour, only muffled noises will be heard in the cabin, which will be almost imperceptible and will not cause discomfort.

In such a situation, it is permissible to use Vibroplast Silver. In this case, the weight of the roof matters. The higher this indicator, the more the shift in the center of gravity is observed. In such a situation, it is worth using a 4 or 8 millimeter Accent. It is allowed to be applied in 2 layers. In this case, it should be ensured that the ceiling covering can be easily put in place.

Down

Soundproofing the underbody helps reduce road noise and stone impact noise. For this, it is worth using the best vibration dampers. They are applied in sufficiently thick overlapping layers. In this case, it is important not to glue the fasteners. Otherwise, when assembling the cabin, there is a risk of problems.

It is worth applying an accent on top. It is better to use a thinner material, but apply it in 2 layers. The wider the coverage area, the better the effect will be. It is recommended to pay particular attention to the wheel arch areas in the passenger compartment. It is recommended to glue them with a sufficiently thick layer. Bimast Bomb is used as a vibration isolator. In its absence, it is permissible to use Vibroplast Gold.

Trunk

Lots of squeaks and noises can be heard in the trunk area. Therefore, it is not recommended to skip this area. Particular attention should be paid to the spare wheel arch.If possible, it should be completely covered with vibration-isolating material.

The next layer is an accent sound deadening material. After cutting, it is recommended to glue the trunk with Bitoplast. This material helps eliminate creaking.

Wheel arches

Thanks to the soundproofing of the wheel arches, it is possible to make the interior more comfortable. To get good results, it is worth doing the following:

- Remove the wheels.

- Remove the plastic wheel arch liners. These parts should not be thrown away as they are excellent sound insulators.

- Remove the dirt and paste vibration isolation agent on the arc surface. It is better to choose Gold class Vibroplast.

- A great option would be to use a liquid solution of Noxidol. It is easy to apply and works very well. It is lightweight and provides excellent corrosion protection. With arches it is allowed to process the bottom from the outside.

- In addition, it is allowed to carry out soundproofing of the wheel arch linings.

- Then you have to glue the Vibroplasts of the Silver class and put them in place.

- If the work is done correctly, the impact of the stones will not be heard.

Stage

Before starting work on soundproofing the car, you need to completely disassemble the interior. For best results you will need to remove the seats, shifter trim and handbrake trim. It is also advisable to remove the dashboard. This will help bond the motor shield.

It is better to make cardboard templates first. Their use allows the vibration isolation material to be used as efficiently as possible. All actions should be performed in a warm room. Otherwise, you should not count on a good fixation.

Thorough cleaning and degreasing of the bonded surfaces is of considerable importance. To achieve a perfect fit of the parts, the material is heated with a hair dryer and pressed to the floor. Then the coating is smoothed with a roller or spatula. In the most difficult places it is permissible to do this with the hands.

Maximum results are achieved with 2 coats. First, a vibration-absorbing material is used, then a sound-absorbing material.

Engine compartment

This manipulation can be part of the complete soundproofing of a car or it can be carried out specifically for the engine compartment. If a full procedure is planned, the engine treatment is carried out last.

In this case, the exterior of the engine compartment has already been partially insulated. When soundproofing the cabin, the master processed the bulkhead, while processing the wheel arches - the outer part of the engine compartment. The noise was also partially isolated.

If the soundproofing of the hood has already been carried out, then it remains to perform simple steps - from the inside to cover the engine compartment with vibration and sound insulation materials.

The main task during the procedure is to create a capsule effect. For this, it is recommended to treat the interior surfaces of the engine compartment as much as possible. It is worth applying the materials in the usual way. First of all, it is recommended to use a vibration absorber, then - to start applying sound insulation.

Additional tips and tricks

To install Shumka, a few recommendations should be followed:

- It is recommended to carry out the procedure in clear sunny weather. The best time to do this is in the summer. The outside temperature should be + 18-20 degrees.

- A single piece of material is applied to the roof and floor.However, it is not necessary to apply it over the entire surface. The work starts from one edge and gradually moves to the other.

- After sticking each material, it is recommended to roll it several times on its surface. This will help remove air bubbles and provide a tighter grip.

- After completing all soundproofing operations, you should not drive the car for 12-24 hours. It is important that the adhesives of the substances are completely fixed.

To carry out the soundproofing of a car, a number of important recommendations should be observed. First of all, you need to choose the right material and strictly follow the rules of its application.