Instructions on how to properly install and repair the sink yourself

The sink is an irreplaceable assistant in the kitchen for every housewife. There are many different modifications on the market that have a variety of features and quality. If you can't find anything suitable, you can assemble the sink with your own hands and bring your own ideas to life. Let's see how to properly install a sink in your own kitchen and what you need to prepare for it.

Kinds

Before buying materials and tools for assembly, you need to decide how the future sink will look. Despite the wide variety of models, all of them can be combined into several groups:

- corner;

- trapezoidal;

- roadmaps.

Corner

Corner sinks work well in small kitchens, where along with functionality, size and ease of installation are valued.Suspended sinks are used for them, as they are the easiest to install. Advantages of choice:

- ease of use;

- space saving;

- a large selection of sinks for the implementation of the idea.

Direct

Direct washbasins belong to the basic versions and are used in a large number of apartments. They are more spacious than other varieties, but they also take up more space, not allowing the maximum use of the volume of the kitchen. For direct sinks, built-in sinks are used, which are easy to find in any specialty store.

trapezoidal

Housewives who prefer a custom kitchen set can turn to trapezoidal designs. They allow you to save space in the room as well as angle variations, while looking extraordinary. They are not as widespread as the previous options, but they are not inferior to them in terms of comfort and functionality.

cabinet material

After the type of the future pedestal has been determined, it's time to move on to the choice of material from which it will be made. This will affect the durability of the structure and its practicality.

Requirements

When choosing a suitable material for building a structure, the following parameters are taken into account:

- practicality;

- moisture resistance;

- aesthetic;

- wear resistance.

Moisture resistance

One of the key parameters that directly affect the service life of the sink. If its moisture resistance is minimal, be prepared to remodel your kitchen in the near future. The most common moisture-resistant materials:

- laminated particleboard;

- Plastic;

- aluminum;

- solid wood.

Practicality

Don't chase weird materials that aren't suitable for use in high temperature and high humidity conditions.Remember that the main thing in a sink is practicality and functionality, while visual appeal takes a back seat.

Wear resistance

The wear resistance of a material is determined by its ability to withstand constant exposure to external factors, expressed as:

- friction;

- blows with blunt objects.

If the material is not wear-resistant, it will quickly deteriorate and its appearance will become less attractive.

Aesthetic

Every kitchen owner wants the headset, in addition to being durable, to have an attractive appearance that harmoniously fits into the interior. Of course, you should not sacrifice the practicality of the material for the sake of beautiful packaging, but it is also not necessary to make a sink from a rough piece of wood.

What is used

As mentioned above, as a common material for sinks that meets all requirements, the following are most often chosen:

- chipboard;

- MDF;

- solid wood.

They have their pros and cons, which should be discussed separately.

chipboard

Chipboard is an abbreviation that stands for laminated particle board. The principle of its manufacture is similar to the production of chipboard. The only difference is the coating with a special film, which includes:

- paper;

- melamine resin or special varnish.

Such material is resistant to moisture and temperature extremes.

MDF

For the first time, the material appeared on the American market, in oblivion in 1966. It includes wood chips, which are pressed into a monolithic sheet under the influence of high temperatures. Positive material properties:

- water resistance;

- fire resistance;

- resistance to harmful microorganisms.

Solid wood

Solid wood is understood as a material consisting of a single piece of wood. Solid wood structures have the greatest durability and functionality, losing to competitors only in price. Some types of wood, before being used for construction purposes, must be treated with special agents in order to increase resistance to any type of impact.

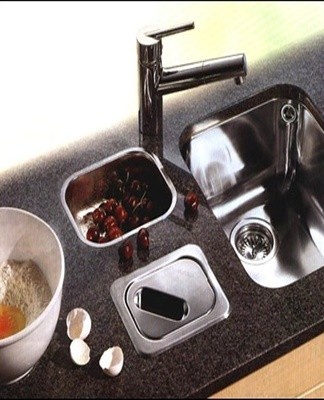

Hull material

The choice of material from which the sink is made should be approached no less responsibly. The stores offer a wide range of products, which you should choose wisely. Experts recommend paying attention to products made from:

- Stainless steel;

- artificial stone;

- ceramic.

To note! Try not to skimp on the selected materials, buying the most budget options.

Inexpensive products deteriorate quickly, requiring extra money for repairs or complete replacements.

Stainless steel

The choice of most buyers who want to install a high-quality and inexpensive product in the kitchen. Material benefits:

- easy;

- does not deform when the temperature changes;

- impervious to moisture and vapor;

- is cheaper than its competitors.

The only drawback is considered an ordinary appearance, which does not give the interior any individuality.

Rhinestone

The composition of artificial stone used in the manufacture of kitchen sinks includes:

- stone chips;

- dyes;

- polymers;

- natural ingredients.

The advantages of the material include:

- strength;

- a variety of shapes and colors, allowing you to give the kitchen individuality;

- dirt does not accumulate on the surface of the sink, since the material does not have pores;

- dampens the sound of water, due to its massiveness.

There is only one drawback - the cost.

Ceramic

Ceramic is a cross between stainless steel and artificial stone, harmoniously combining their positive qualities. Material benefits:

- silence during operation;

- attractive appearance;

- easy to clean;

- Resists moisture, temperature extremes and chemicals well.

Disadvantages:

- the price;

- Product weight.

Standard sizes

In order to fit the sink harmoniously into the worktop, you need to know its exact dimensions. For novice builders who first took up the installation of a sink with their own hands, it is recommended to base themselves on the standard dimensions:

- the distance from the edge of the sink to the wall is 5 centimeters;

- bowl depth - 17 centimeters;

- side length for a square sink - 50 centimeters.

Of course, the sizes can vary depending on the individual preferences of the owners and the characteristics of the kitchen. These numbers are considered the benchmark, allowing you to use the sink comfortably and efficiently.

Tools and materials

In addition to the sink and materials for the sink, it is necessary to prepare the tools with which the products will be installed in the kitchen. You will need:

- Sandpaper;

- lumber;

- self-tapping screws;

- antiseptic;

- putty and primer;

- jigsaw;

- fittings;

- drill;

- Screwdriver;

- roulette;

- Screwdriver set.

Lumber

The wood is purchased according to the drawing of the sink. The durability and practicality of the structure will depend on the quality of the wood.

You should not save on them by buying low-quality wood.

Sandpaper

Useful when processing wooden sink parts. Using sandpaper allows you to:

- To make the material more attractive in appearance and pleasant to the touch.

- Eliminates splinters and sharp corners that can injure household members.

It is advisable to purchase coarse, medium and fine grain paper, for high-quality and consistent processing of the material.

Antiseptic for wood processing

To increase the durability of wood and improve its protective qualities, the surface of sawn timber is treated with special antiseptic agents. Necessary:

- Protect yourself against moisture, as the parts of the sink are in constant contact with it.

- Increases resistance to high temperatures.

- Protect wood from the harmful effects of microorganisms that appear in large quantities in the kitchen due to their comfortable environmental conditions.

Screws, self-tapping screws

No construction site can do without it, especially when it comes to working with wood. With their help, wooden structural elements and other parts used in the assembly process will be connected.

Putty and primer

Putty is necessary to eliminate defects in wood, expressed in the form of chips, cracks and irregularities. The substance evens out the treated surface, increasing its attractiveness.

After putty, a primer is applied, the main task of which is to provide a reliable basis for applying varnish or paint.

It acts as a connecting element, increasing the durability of the structure.

Fittings

Hardware refers to auxiliary structural parts used for final assembly. Accessories include:

- door hinges;

- pens;

- guides for drawers;

- latches;

- closures;

- locks.

Electric jigsaw

An irreplaceable thing when working with wood, which makes it possible to cut out any part of the desired size and shape. Significantly speeds up the assembly process.When working with a jigsaw, you need to be careful and do not forget about safety rules.

To note! It is recommended to stock up on spare jigsaw blades as they tend to break at the most inopportune moment.

Drill

Another auxiliary tool, the presence of which will significantly speed up the process of assembling your sink. It is difficult to do without it; if the drill is not at home, borrow it from the neighbors.

Screwdriver

Effective replacement for conventional screwdrivers, making the assembler's job faster and easier. This is an optional tool and can be replaced with a standard screwdriver set.

Tape measure, ruler and pencil

An irreplaceable trinity, without which it will certainly not work to install a sink. Of course, you can measure the dimensions with the naked eye, but you will definitely not like the end result.

screwdriver set

Necessary for tightening screws and self-tapping screws. Any kit sold at a hardware store will do.

How to assemble with your own hands. Instructions

To assemble a sink with your own hands, it is not enough to buy materials and components. It is necessary to follow a certain sequence of actions and have at hand a ready-made design scheme.

Assembly includes the following steps:

- we prepare the details;

- we pick up the curb;

- we install a siphon and a tap;

- sink installation;

- communications connection.

Preparation of parts according to the scheme

Before starting the assembly, it is important to prepare and check all the parts according to the existing diagram.If this is not done, the assembly will have to be stopped to search for missing parts, which will affect the time of installation work and the quality of the final structure.

Assemble and install the curb yourself

To assemble and install a coping in the kitchen, you will need:

- plywood for the back wall;

- base material, cut according to drawing;

- fittings;

- facing tape in an appropriate color.

Installation of a crane and a siphon

A faucet and a siphon are mounted on the sink, before placing it on the cabinet. This is necessary to ensure the convenience of work, since it is time-consuming and inconvenient to connect the necessary elements under the sink.

Install a sink on a vanity unit

Algorithm of actions when installing the sink:

- we attach the plastic corners to the upper ends of the side walls;

- on the edge of the walls on which the sink will rest, a layer of sealant is applied, which serves as a fastening;

- install the sink and lean it against the main structure.

Communications Login

We connect the sink and siphon to communications and check the build quality for leaks. If all goes well, we use the car wash as usual.

Rules of operation

During operation, observe a number of rules that will increase the service life of the structure:

- Wipe down the sink after each use.

- If scratches appear on the stainless steel, treat them with a protective compound. This will save the material from destruction. Treatment is carried out once every 2 months.

- Do not use washcloths made of hard material to clean the sink. Avoid detergents containing abrasive materials.