Varieties and colors of wax paints for wood, top 5 brands and how to apply

Wooden products lose their original appearance over time. This material is covered with a poorly removable plate. Wood wax paints help to increase the life of these products. Such a composition is available in several forms, each of which is used under certain conditions. At the same time, the wax makes the treated surface shiny, making the product stand out against the background of the interior or environment.

When to use wood wax

The wax is mainly used for outdoor use. The material is used to update:

- wooden facades of buildings;

- fences;

- gazebos and other products.

The composition of the wax directly affects the field of application. In some cases, this material can only be used indoors. The use of wood wax is not limited to the situations described. The composition contains organic components, so the material is used for processing, including products for children. Once the wax has hardened, the wood receives additional protection against extreme temperatures, high humidity and direct exposure to sunlight.

Varieties

There are three types of wax paints: solid, liquid and colored. This gradation is carried out taking into account the type of components that make up the material.

Solid

The solid material consists of vegetable oil and natural ingredients. Basically, beeswax is used for making this product. This material is used at various stages of construction work, as well as to remove large defects on the surface of wood.

This product has the following features:

- the ability to penetrate deep into the structure of wood, filling voids;

- increased plasticity;

- provides protection against mechanical stress.

You can work with such a composition at temperatures from +10 to +25 degrees. To impregnate wood with hard wax, you will need:

- impregnation (linseed oil);

- sander;

- pewter container;

- woolen or woolen cloth;

- brushes.

This material is applied to the surface according to the following algorithm:

- With the help of a grinding machine, the irregularities of the wood are eliminated.

- Impregnation is applied to the prepared surface. After drying, the wood is sanded again.

- In a pewter container, the wax is pre-melted, which is then applied to the wood with a piece of cloth. In this case, you need to move in the direction of the base fibers.

- After drying (the duration is determined by a specific manufacturer), the excess material is removed from the wax layer.

At the end of the manipulations described, the treated surface must be re-sanded. In some cases, the impregnation and the wax will have to be applied several times. A similar approach is used when heavily damaged items need to be restored.

Liquid

For processing wood with a pronounced pattern, it is recommended to use liquid wax, which emphasizes the texture of the surface. This composition penetrates the structure better than the solid, and therefore the material is more often used to restore furniture.Among the characteristics of liquid wax are the following:

- easy to apply;

- ecological;

- provides moisture resistance;

- able to hide scratches and small chips;

- forms a film that repels dirt and dust.

To apply wax paint, brushes or rollers are used. The surface treatment with this material is carried out according to the following algorithm:

- The surface is cleaned of dirt and sanded.

- Liquid wax is applied to the prepared surface. If you have to work on embossed wood, it is recommended to use a brush. In other cases, the composition is applied by roller.

- After the treated surface dries, the applied layer is additionally sanded with a cotton cloth.

Due to its dense consistency, the liquid wax does not spread and forms an even surface layer.

Color

Colored wax is often used to restore old furniture. This product can also be used to change the shade of the support. When choosing a suitable color, you should be guided by the following rules:

- black and brown shades are suitable for oak;

- for cedar and pine - golden;

- for mahogany - "warm" shades of red or orange.

It is forbidden to use colored wax to restore household objects (chairs, tables, etc.). This is explained by the fact that the applied composition, even after drying, is capable of leaving noticeable stains on clothes. A correctly selected palette of shades makes it possible to use this product to hide the defects of the painted surface. This approach is also used for color alignment on wood products.

Colored wax is available in liquid form. Therefore, the material is applied according to the algorithm described above.

Main Manufacturers

A number of wax formulations have additional characteristics not listed above. This is because manufacturers often include additional components in the initial mixture.

Liberon

This material is backed up by the fact that Liberon wax can be applied to the stain, creating an extra layer of protection.

V33

When buying V33 products, it is recommended to first take a small jar to test the behavior of the wax after being applied to the wood.

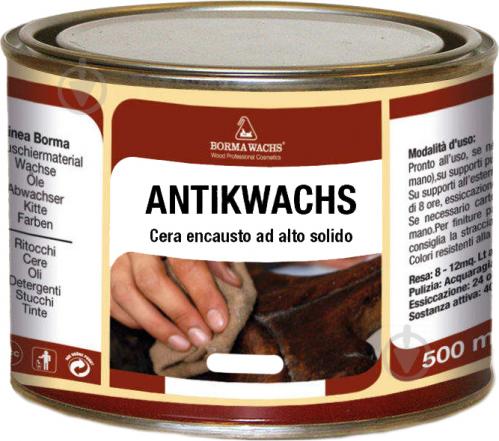

Borma watches

This wax can only be purchased for smooth surfaces.

man

No defects were found in Homa products.

"FNP VAPA"

When choosing this product, it should be borne in mind that some formulations, due to additional components, are devoid of the indicated disadvantages.

Advantages and disadvantages of waxing wood

Thanks to the waxing of the wood:

- an additional protective layer is formed;

- a glossy surface is formed;

- the natural warmth and texture of the wood is preserved;

- moisture resistance increases.

Polishing is not recommended for wood stained with water and UV rays. In addition, this material is not able to withstand the effects of liquids containing alcohol and does not tolerate contact with devices of heating.