Composition and types of epoxy paints, rating of the best brands and calculation of consumption

Epoxy paint is mainly applied to metal surfaces. This is due to the fact that epoxy-based materials have pronounced anti-corrosion properties. It is based on resins obtained in a special way. These substances resist oxidation and attack by halogens. Paints can have intense colors, depending on the presence of pigment.

Characteristics of epoxy paints

Epoxy finishes protect metal objects from natural corrosion. The paints are based on epoxy resins, which are oligomeric substances. They exhibit the ability to form glossy, dense coatings when exposed to a hardener.

The main properties of epoxy paints:

- resistance to attacks from halogens, acids, alkalis;

- high adhesion to metal surfaces;

- physical characteristics: are yellowish liquid;

- After adding pigments, the resins can have different colors, ranging from white and transparent to dark red;

- epoxy is harmless under normal conditions of use.

Despite the distinctive properties of epoxies, they are most often used in industrial conditions. Resins are commonly used to paint metal, concrete or reinforced concrete structures.

You can paint your living space with epoxy. The main advantage of epoxy paints is the ability to cover wet concrete. As a rule, all coloring bases are applied only on a dry surface. This is not necessary when using epoxy.

Epoxy-based paints are completely waterproof. They have electrical insulation properties, have high heat and fire resistance. In addition, bacteria do not grow under the coatings and corrosive processes do not occur.

Composition and specifications

The composition of epoxy enamels contains the following components:

- Thinners. Substances, which allow rapid connection of certain elements with others.

- Pigments. These are coloring elements, with their help the selected shade is obtained.

- Fiberglass. One of the main elements that provides the thermal stability of the composition.

- Hardener. The presence of this component contributes to the rapid polymerization of the applied layer.

- Bindings. Various elements to improve viscosity and create a special structure.

Most often, epoxies have specific properties:

- resistance to exposure to chemicals;

- resistance to atmospheric precipitation;

- the formation of a durable and elastic layer.

Resins have different technical characteristics. At first glance, the consistency of the composition is viscous and viscous, but when diluted with special solvents, the structure changes, it becomes more liquid.

Scope

The properties of the enamel determine the field of application. Paints are used in the following cases:

- for painting metal, cast iron structures;

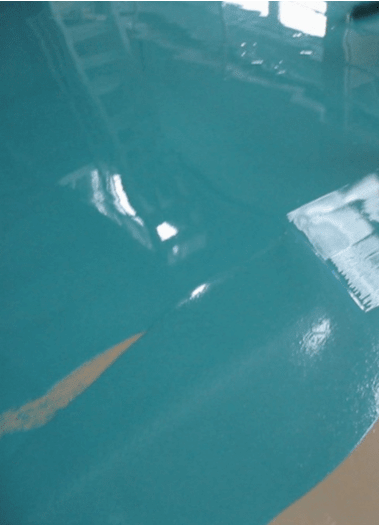

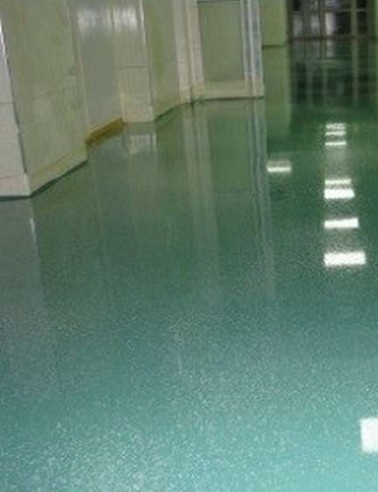

- to cover concrete, ceramic or wooden surfaces;

- for interior painting;

- to create a coating on the outside of the facades of different materials.

Glazes are suitable for coating ceramic bathtubs, they are often used as the main finish for the restoration of old coatings. When using compositions with pigments, they paint household items and interior items, as well as park or garden compositions. Powder paints are used for car repairs, with their help they renew coatings on engine parts. Radiators and heating pipes are coated with a two-component white enamel.

Advantages and disadvantages of paint material

Epoxy resins or paints are durable and tough compounds that can be used in a variety of climates.

| Benefits of using | Defaults |

| Resistance to aggressive chemical elements | High price |

| Lack of yellowness | Powder coated paint begins to yellow with spots |

| weather resistant | |

| Water resistance |

Hard epoxies are known to form coatings that have a high level of water resistance when operating conditions are met. They can be used as electrical insulating materials and have heat resistant and self-healing properties.

Varieties and recommendations for choice

Epoxy enamel paints are conventionally classified by type of application and composition. Different application techniques are applicable to each type.

Covered in powder

Powder coating is a special type of coating created on a surface exclusively in an industrial environment. The paint is applied using a special device, inside which pressure is additionally created by connecting to the electrical network. Benefits:

- the most durable coating;

- resistance to the aggressive influence of external factors;

- operating time.

Disadvantages:

- requires special skills when applied;

- used in compliance with strict operating rules.

Epoxy powder coating is used for painting various objects, equipment, walls in the room.

Two-component formulations

It is the most common type of siding and is used for interior living spaces.

Benefits:

- create a durable and elastic coating;

- Assorted colors;

- ease of use.

Disadvantages:

- short shelf life;

- the need to work in certain temperature conditions.

Two-component paints are applied by roller, brush or spray gun.

Spray epoxies

Spray application is convenient and effective. The paint is poured into designated containers and sprayed from a certain distance.

Benefits:

- uniform coverage;

- ease of application;

- the ability of the surface to self-clean;

- elastic layer, the formation of air bubbles is excluded.

Disadvantages:

- you must have skills to work with a spray gun;

- special rules of application technique must be observed;

- high price of aerosol formulations.

The spray-applied layer is usually particularly resistant to scratches and damage.This is due to the fact that in all areas of the coating it remains uniform and of the same thickness.

Ranking of the best brands of two-component epoxy paints

Glazes can be two-component or multi-component. Each painting must meet specific requirements.

"Epostat" enamel primer

A durable two-component enamel with the following properties:

- lack of reaction to chemical influences;

- anti-corrosion properties;

- increased wear resistance;

- dries quickly in 2-3 hours;

- you can work at temperatures from -120 to +40 degrees;

- complete coating preparation occurs 7 days after application.

If we talk about the consumption of floor enamel, then 160-200 grams are used per 1 square meter. In this case, a film layer is obtained with a thickness of 80-100 microns.

"Sipoflex 24"

American brand epoxy resin. Basic properties:

- increased adhesion to cast iron and metal surfaces;

- elasticity of layers;

- good fluidity;

- the maximum drying time is 24 hours;

- the composition does not have a strong pronounced smell.

One of the disadvantages is the possibility of forming air bubbles during the dyeing process. After complete hardening, Sipoflex offers a smooth and shiny surface.

Classic Plastfoil

An enamel that creates a durable coating on cast iron, metal or ceramic surfaces. It can be applied to plastic, wood or concrete. Liquid enamel has the following properties:

- lack of yellowness;

- surface color retention of 5-8 years in a row;

- solidification time 36 hours;

- creating a strong and durable odorless coating.

The paint is produced in cans with a tightly screwed lid; after opening, the container cannot be stored for more than 1 month.

Specificity of use

Epoxy paints have advantages and disadvantages. The functionality of the application is clearly regulated by special instructions, created in accordance with generally accepted standards.

For metal

Two-component compositions are most often applied to metal surfaces. The resins begin to harden at room temperature. This is called the cold cure effect. The resulting film has high strength properties.

Epoxy Metal Enamel Primer is applied to a thoroughly cleaned surface. For application, use brushes, paint rollers or pneumatic guns.

For concrete

Epoxy is traditionally used to paint concrete. Glazes are applied with the mandatory use of protective respirators and the covering of hands with paint gloves.

Before application, the concrete surface must be cleaned of contamination, cement laitance is removed, the coating is degreased for further use with epoxy putty.

Attention! On fresh concrete, the paint is only applied 4-5 days after the cement has set.

For wood

An important condition when working with wood is surface temperature control. If you warm up the tree before work, the air will begin to rise. The pores of the material expand under the influence of temperature and better absorb paint.

Material consumption per 1 square meter

There are several ways to reduce paint consumption. To create a liquid base, add more solvent than needed to the base. This way, the amount of paint used is reduced, but the properties of the created layer are reduced. It is possible that the service life is reduced and the basic qualities deteriorate.

If you use paint according to the instructions, then you need to determine in advance the budget involved in purchasing a certain amount of paint. Usually about 350 milliliters of composition are needed per 1 square meter.

The following factors affect calculations:

- characteristics of the material from which the surface is created;

- absorption capacity of the coating;

- the need to make 2 or more coats to cover the defects of the previous coating;

- method of application;

- characteristics of enamel, the amount of solvent in the composition.

Experts recommend buying such an amount of paint and varnish so that you have a small container in reserve.

Expert advice on the economical use of epoxy

To start working, you need to prepare the paint, properly clean the surface and purchase tools.

Tips for choosing paint:

- First of all, you need to determine on which surface the composition will be applied. If the paint and varnish material is purchased for painting metal or concrete surfaces, then it is better to choose spray paints. They are very resistant to corrosion processes.

- The next step is to determine the conditions under which the paint will be used. When painting interiors, it is better to choose two-component compounds, they fall off easily, create a good shine and are resistant to damage.

- Next, you need to determine the degree of stress. If the room is located inside industrial facilities, where high air temperatures are usually established or the influence of chemicals often occurs, it is better to choose a powder coating that applies and dries quickly.This will prevent possible damage to health, such as when painting industrial objects by spraying in the air.

- The last step is to calculate the area. The larger the size, the greater the amount of paint and varnish.

Additionally, there are special rules for the use of epoxies. Compliance with the listed conditions helps to increase the operating time and makes the work of higher quality:

- The surface is properly prepared. For this, traces of grease and oil residues are removed from it. As degreasers, special substances are used that are applied to the entire surface, left for a while, and then removed with a jet of clean water.

- Additional grinding of the coating increases adhesion rates, therefore, before working on the top layer, they pass with sandpaper or a grinder.

- In order for the coating to be durable and elastic, they wait until the top layer is completely dry, and then proceed to the step-by-step application of the paint.

First, paint hard-to-reach places with brushes or rollers. Then apply the spray or dust method to a flat surface.

At home, a roller or brush is most often used. Both tools have features:

- Roll. To choose if the epoxy enamel is to be applied to wooden, iron or concrete surfaces.

- Brush. Used for spot painting small areas. Experts advise having in your arsenal several devices with different battery characteristics. With a short-haired brush, paint on the corners, the joints, the small protruding details. Long bristle brushes are suitable for large areas.

Attention! To paint hard-to-reach places, special brushes with a long concave handle are used.

Chemical Safety

By themselves, epoxies are harmless. The addition of excipients makes them toxic and difficult to breathe. Solvents are very volatile, therefore, during operation, the following rules must be observed:

- it is strictly forbidden to pour paint into dishes intended for cooking;

- work with paints in protective overalls, goggles and paint gloves;

- epoxies are only stored in closed containers;

- to work indoors, additional ventilation must be provided;

- in case of contact with the skin, wash the area with warm water and soap, in addition treat with denatured alcohol.

The prepared material mixed with auxiliary elements should be used within 24-32 hours after preparation. If the composition has thickened, a little thinner should be added.