Description and composition of acrylic primer, 10 types of products and top 4 of the best brands

Priming is one of the main finishing steps. Acrylic-based compositions are one of the most popular, they perfectly eliminate porosity, make the surface even and durable, increase the degree of adhesion of the decorative coating to the wall and reduce the consumption of finishing material. On a support treated with an acrylic primer, wallpaper, paint, plaster fit perfectly.

Where is acrylic primer used?

The material is designed to increase adhesion, i.e. adhesion to the coating, on various surfaces inside and outside the building. When you use a quality primer, you'll spend less on the final finish.

The acrylic composition is multifunctional, it is used for processing wood and wood-based panels, masonry, concrete, ceiling coverings, for reinforcing plaster and putty before wallpapering or painting .

Acrylic primer is optimal for porous and loose substrates.With a high probability of fungal infection, a composition with an antiseptic effect should be chosen. Information about the acrylic base that can be applied is indicated in the instructions on the label.

You can use acrylic primer instead of glue for decoupage - decorating furniture and interior items using leather, wood, fabric inserts. Then the next layers will easily fall on the surface, paint consumption will decrease. For decoupage, it is advisable to take a colorless water-based primer that does not contain toxic components.

Composition and characteristics of the material

Acrylic is a polymer composition based on acrylic and methacrylic acids. On the basis of the substance, not only a primer is made, but also synthetic fibers, plastic, and also paint, for example, the facade brand Akrial.

Acrylic primer is a liquid formed by an acrylic dispersion.

The rest of the components differ depending on the purpose and properties of the solution, but there are those that are always included in the composition:

- thickeners - resins, drying oil;

- drying accelerators;

- substances with additional properties - antiseptics, foam fire extinguishers and others;

- pigments;

- ballast components.

Acrylic primer has high protective properties. Absorbed in the pores of the surface, it strengthens its structure. Once dry, the acrylic forms a solid film which provides adhesion.

The acrylic primer is available in 3 types:

- powder;

- pasty in buckets for further dilution with water;

- liquid, ready to use, in 10 liter container.

Features

All acrylic primers have the following properties:

- significantly increase adhesion, ensure stable fixation of the finishing material on the surface;

- suitable for the treatment of any surface, not applicable only to protect ferrous metals from corrosion;

- make the base stronger;

- provide reliable protection against moisture penetration;

- reduce the consumption of paint and plaster;

- do not reduce the vapor permeability of the base;

- mask dark areas of the surface, they remain invisible after applying the final light coat;

- are spent economically;

- dry quickly;

- weather resistant.

Acrylic primers are environmentally friendly, suitable for interior decoration and contain toxic components. The expiry date is an important toxicity factor. Expired composition can harm the human body.

Varieties and recommendations for choice

The properties of the primer are determined by the purpose and characteristics of the surface to be treated. A certain type of acrylic composition is intended for each type of work.

For the exterior finish, a primer with higher protective properties is required: anti-corrosion, antiseptic, UV-resistant.

Acrylic primer is not acrylate. In the first, a pure concentrate acts as a binder, in the second, copolymers of acrylates: styrene, latex, vinyl.

Adhesive

As part of the primer, quartz or other filler of a fine fraction, which roughens the base, provides it with reliable adhesion. The adhesive primer is optimal for the treatment of poorly absorbent or water-repellent materials: monoliths, glass, ceramics, plastic. The composition often contains pigments, which allows you to see uncoated areas during work. The average consumption is 1 liter per 5 m2.

Benefits:

- excellent adhesion to any surface;

- environmental friendliness, absence of toxic components;

- the possibility of dilution with water or an aqueous solvent;

- drying in 4 hours;

- at low price.

Disadvantages:

- cracking and crumbling due to improper application, covering a dirty area;

- the inadmissibility of mixing solutions.

Anti corrosion

Designed for metal processing. It can be water-based or latex. Contains substances that prevent corrosion by forming a dense film on the surface. The anti-corrosion primer is used both as a paint base and as a finishing coat.

Benefits :

- color stability, the ability to paint surfaces that are constantly exposed to ultraviolet rays;

- low probability of cracking due to the elasticity of the acrylic film after drying;

- long service life of the processed material: 10 years - wood, 20 years - metal;

- resistance to oils, aggressive chemicals.

Defaults:

- the need for thorough cleaning and degreasing of the treated surface;

- high price.

Deep

Deep penetration acrylic primer, due to its inclusion in the latex composition, intensively penetrates the structure of the material to be coated, reaching a depth of 10-12 cm, without leaving a surface trace. A deep primer is often used on old concrete, aerated concrete, plasterboard and other materials with increased friability. Designed for interior and exterior decoration. Consumption when applying one layer - 1 l per 10 m2.

Benefits:

- excellent adhesion to any surface;

- environmental security;

- the possibility of dilution with water;

- lack of pungent odor;

- drying in at least 40 minutes.

Disadvantages:

- considerable cost;

- the complexity of dilution to create the desired concentration.

For concrete

The primer is intended for the treatment of materials with high porosity before the subsequent application of enamel paints, plastering or tiling. Dries, on average, in 5 hours.

Benefits :

- ensure high adhesion;

- optimal coating for concrete walls and floors;

- at low price.

Defaults:

- undesirable use in a room with high humidity;

- high concentrate consumption.

For wood

The primer, containing antiseptic and antibacterial components, protects the wood from rotting, mold and insects. Designed for interior decoration and finishing of wooden furniture and doors. Average consumption - 1 liter per 10 m2, a wood primer should be applied in 2-3 layers.

Benefits:

- harden the wood, improve the adhesion to the finish;

- accelerated drying;

- absence of toxic compounds and irritating odor;

- ensure economical paint consumption thanks to its uniform application on the treated surface;

- the possibility of grinding after processing and drying of the surface.

Disadvantages:

- low resistance to humidity and negative temperatures;

- inability to use for exterior decoration;

- consumption may be higher than standard, depending on the structure of the wood.

Impregnation

The transparent acrylic primer is intensively absorbed into the material. It is usually applied in several coats to regulate the moisture absorption of the substrate.

Benefits :

- reinforcing materials with an uneven surface structure;

- reinforcement of the base to a depth of about 10 cm.

Defaults:

- risk of impregnation heterogeneity;

- the formation of overlaps during sloppy work.

Special walls

Modern manufacturers produce acrylic primers with antiseptics, UV resistance, high color retention. They have standard properties: they are suitable for processing materials at any level of humidity, are intensively absorbed, dry quickly, provide increased adhesion and save finishing materials.

Benefits :

- protection of walls from mold, biological pathogens;

- crack prevention;

- decrease in hydrophilicity;

- prevent the exhaustion of the walls;

- preservation of the structure and color of the material.

Defaults:

- the need for prior cleaning and disinfection of the surface if it already contains pathogenic microorganisms;

- if the wall is low porosity wood, a liquid acrylic primer is required.

Reinforcement

The primer does not penetrate deep into the structure of the material, but contains microscopic adherent particles, thanks to which it acts like cement. It is most often used to coat mineral-textured substrates.

Benefits:

- effective filling of pores and cavities;

- smoothing of irregularities;

- prevention of the chalking effect.

Disadvantages:

- the formation of a surface film after drying;

- if the base is complex, it is advisable to use a deep one before applying a fortifying primer.

Universal

The most popular acrylic primer. Provides the necessary surface roughness for strong adhesion, combines the working qualities of the above compositions.

Benefits:

- multifunctionality;

- deep penetration into the structure of the base;

- alignment of the absorbent properties of the surface.

Disadvantages:

- medium quality;

- lower efficiency of each property compared to the soils described above.

Dispersible in water

Primer for interior decoration. Unifies the absorbent properties, strengthens the base. It is mainly used for wood and wood-based panels. A pigment is often added to a water-dispersing primer to control the quality of the treatment and to increase the aesthetics of a wood surface.

Benefits :

- environmental friendliness, absence of toxic components;

- saving the consumption of materials for finishing.

Defaults:

- instability to adverse environmental factors;

- final finish only after complete drying of the floor.

Ranking of the best brands of acrylic primers

To achieve the desired result, it is necessary to purchase high-quality acrylic primers with the required technical properties. Below are popular and proven manufacturers of primers.

St. Mark

The Italian company is one of Europe's leading manufacturers of finishing products. Manufacturing technologies are constantly updated, so the quality of products remains unchanged.

Portici Acrylic Primer for Interior Finish is suitable for plaster, concrete and drywall. The composition penetrates deep into the structure of the base, provides perfect adhesion. For a high quality result, it is enough to apply one layer, the coating dries in 40 minutes.

"Lakra"

The Russian company produces finishing products on the best modern equipment with the passage of production control at all stages, uses high-quality foreign raw materials.

Acrylic primers from the Lakra company are presented on the market in a large assortment, so there is no difficulty in choosing a suitable composition. In addition, almost all types of acrylic products have an antifungal effect.

"North"

A Russian manufacturer specializing in building and finishing materials produces acrylic primers, which in terms of quality characteristics are not inferior to many foreign analogues. In addition to production workshops, the company "Nord" has laboratories, where they develop original technologies for creating products.

"Nortex-Grunt" Acrylic Primer is suitable for coating wood, masonry, concrete, stone, interior and exterior, as well as plaster and gypsum blocks. The composition includes antifungal components. Primer is consumed sparingly. It is colorless, but you can add a pigment of the desired tone to it.

Stacks

A large Russian manufacturer produces universal and environmentally friendly products using modern technologies, in accordance with global quality requirements.

Acrylic water-based "Halo" primer is inexpensive, while it is suitable for exterior and interior decoration, contains antiseptic components, makes the surface absorbency uniform everywhere. A ready-to-use primer is being put in place. After application, it dries in one hour maximum.

How to work with an acrylic primer

Various tools are used to apply the primer:

- Brush. A neat but time-consuming working method. The minimum consumption is 80 g/m2.

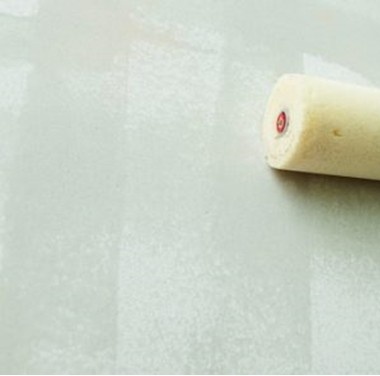

- Paint roller. Provides fast, even surface coverage. Consumption - 100 g/m2.

- Spray gun. Convenient working method, especially if the area is large. But not profitable. Soil consumption exceeds 120 g/m22.

The consumption of acrylic primer is determined by the surface to be coated. The table contains standard values, but they do not always coincide with the information specified in the manufacturer's instructions. Therefore, it is best to focus on the recommendations on the label and also perform a test application of the primer on a small section of the wall.

| Processed material | Soil consumption rate per layer, g/m2 |

| concrete | 350 |

| drywall | 100 |

| plaster, putty | 350 |

| decorative coating | 200 |

| metal | 100 |

| drink | 120 |

| aerated concrete, wood-based panels | 150 |

For successful treatment with an acrylic primer, follow the following algorithm:

- Prepare the composition according to the instructions on the label.

- Using a suitable tool, cover the surface. Let dry.

- When the first coat is dry, apply the second. If necessary - the third.

- Wait until it is dry. Proceed to final finishing.

Drying time

Drying times vary for different acrylic primers. It is influenced by the surface structure, the thickness of the superimposed layer, the microclimatic conditions. A water-based primer, for example, dries in an hour on average. Most acrylic primers dry between 4 and 12 hours.

The primer will dry faster, if you apply a thinner layer, increase the temperature.

Storage conditions

The shelf life and production date are not the same for the different primers, they are indicated on the label. For example, for deep acrylic floor, it is 12 months. But the expiration date is valid only if the rules of conservation of the composition are respected.

The acrylic primer should be stored:

- in a tightly closed factory container;

- in a shaded place;

- away from radiators and other heat sources;

- in a place where the temperature does not fall below 0°C.

After opening the container and pouring the earth, the shelf life is significantly reduced. Dilute exactly as much primer as needed for the work day.

Recommendations from the masters

In order for the primer to reliably protect the surface, consider the following recommendations when purchasing and using it:

- Choose a universal primer for coating different materials at the same time.

- Use a facade primer for exterior walls. For domestic - environmentally friendly.

- If you need an odorless, quick-drying compound, use a water-based or latex primer.

- Ask the seller for a quality certificate. Quality products should have it. Do not buy a primer that does not meet the requirements of GOST.

- Thoroughly mix the finished acrylic solution before use.

- Do not treat the same surface with different types of primer.

- Smooth surfaces such as plasterboard should be covered with a paint roller. This is not only convenient, but also saves material.

- Cover the raised surfaces with a brush. Treat corners and hard-to-reach areas the same.

- Before work, especially if you plan to use a spray gun, wear goggles and a respirator.

- Take your time applying the last coat until the first coat of primer is completely dry. You may need to apply a second coat for a good result.

When choosing an acrylic primer, carefully read the composition. The working properties of the solution depend on the components: antifungal, anti-corrosion, fortifying. The certificate must indicate not only the components, but also their percentage.

Water-based primers are economical, for solutions based on organic resins, consumption is higher. Pay attention to the pigment content if the final finish is a clear lacquer.