Instructions for imitation wood paint and top 10 suitable compositions

Imitation wood, or faux wood, is a finishing material similar to siding. The difference is in the thickness of the board and the end result. Panels that imitate wood are wider and thicker, have no steps on the outside, like a lining. They are arranged horizontally. The wall looks like it's made of real logs. The panels are made from conifers. Therefore, the imitation of a bar is subject to painting, varnishing and other types of finishing of natural wood.

Targets and objectives

The exterior and interior walls of the buildings are lined with a false beam. In either case, the wood must be treated to prolong the life of the siding. The wooden facade is exposed to precipitation, cold and ultraviolet rays. Indoors, the panels are exposed to high temperatures, humidity or dry air.Both types of coatings are sensitive to mechanical damage: shocks, scratches. Untreated panels are less easy to clean, destroyed by household chemicals. Therefore, the main purpose of imitation wood paint is to protect against harmful environmental influences.

Finish Coating Task:

- protect from external moisture, ultraviolet radiation;

- prevent the appearance of fungi, xylophagous beetles;

- do not interfere with the evaporation of moisture from the walls;

- maintain the shape and structure of the tree.

Faux painted wood is less susceptible to warping and cracking, but only if durable paints and varnishes are used. A poor quality siding will crack first, and the panels will follow. Apart from the practical purpose, painting has an aesthetic purpose. A bar made of inexpensive material receives a noble look from valuable wood with the help of finishing. Staining and toning allow you to match the cobblestone interior walls to the color palette and style of the room.

Advantages and disadvantages

The panels of a faux wood are connected like a lock. Their natural color depends on the type of wood from which they are made: light species - pine, larch, dark - ash, oak, beech.

The parameters of the panels imitating wood allow them to be adapted to large and small displacement surfaces:

| Name | Dimensions (edit) |

| Thickness | 16-37mm |

| Width | 110mm and above |

| Length | 2-6 meters |

According to the type of processing, natural wood and thermal wood are divided. The second type of panels has less thermal conductivity and is less prone to rotting.

General positive aspects of raised beam cladding:

- the finish is safe for health and the environment, as the panels are made of an environmentally friendly material;

- less weight compared to natural wood, so the imitation can be mounted on bases that are not designed for heavy loads;

- inside the room, heat and sound insulation increases, it is not necessary to lay insulating material between the wall and imitation panels;

- thanks to the interlocking connection, the panels are quickly assembled and easily replaced in the event of damage.

Faux wood is a rare finishing material with a short list of drawbacks:

- flammable, like any wood product;

- sensitive to harmful atmospheric influences.

Some disadvantages are eliminated by painting and varnishing. Imitation wood is popular for its many advantages, which also include a wide range of prices for different types of wood and beauty.

Appropriate dyes

Most paints and varnishes for woodwork are suitable for the imitation bar design, but each has advantages and disadvantages.

Impregnation

The compositions are divided into three protection groups:

- antipenes - from fire;

- antiseptics - against insects and mold;

- bioprene - universal.

Positive qualities of impregnation for wood:

- not have an unpleasant odor;

- dry quickly;

- not emit toxic substances;

- can be applied on damp surfaces.

Water-based impregnations are more commonly used. The first disadvantage is that the compounds lift the fibers of the wood panels. Therefore, before applying the water-based impregnation, the wood should be slightly moistened, and the next coating should be applied after it is completely dry.

Other disadvantages:

- superficial penetration;

- not suitable for protecting wooden panels in damp rooms.

Organic impregnations penetrate deeper into the structure of the tree and are more resistant to moisture, but smell bad. Their protective properties last from three months to six months.

Bleach

The compositions are used to lighten the natural dark color of wood, there are chloride and oxygen.

Gloves and safety glasses should be worn when handling bleaches. Residual salts are washed off the surface with citric acid dissolved in water at the rate of 40 grams per liter.

Natural linseed oil

The oil covers the panels with a transparent film, which favorably emphasizes the grain of the wood. Linseed oil is used to treat ceilings and small structures that are not subject to friction.

Despite the laborious application process, the oil coating retains the properties of wood, which is especially important for valuable species.

Natural drying oil

The improved version of olive oil hardens better on wood due to chemical additives in the composition and heat treatment during manufacture.

Hemp oil is sometimes substituted for olive oil. Chemistry has not managed to completely overcome nature - the strength of the coating is significantly lower than that of paints and varnishes. Drying oil is applied to dry, degreased panels at 80 percent humidity. Uneven oil distribution leads to staining.

Wax

Compositions based on natural wax and its analogue, paraffin, are often used to process wooden panels.

The disadvantages also include abrasion, but worn places are easy to restore.

Stain

Stains, or stains, are divided into water and organic, powder and liquid.

The stain enhances the wood grain of the panel. After staining, the wood must be varnished, otherwise it will remain vulnerable to atmospheric and mechanical influences.

Azure blue

The popular stain compound does not overlap the natural pattern of the wood panels. Azure is similar to varnish, but has lower covering power.

Damaged Azure is easily restored. For the treatment of imitation of a bar, thin-layer and medium-layer compositions, prone to abrasion, are suitable.Thick layer glazes are used on small elements and are distinguished by surface penetration.

Aqualak

The difference between the composition and the usual varnish is the water base. The hardcoat is formed from acrylic.

For long intervals between applications, the coating does not spread evenly.

Acrylic coatings

Acrylic paints are suitable for facade and interior imitation of wood. In some formulations, defoamers are added to increase heat resistance, but their price is higher.

Latex paints

Compounds containing rubber are durable and adhere well to the smooth surface of the finishing beam.

One coat of latex paint dries in 20 minutes. Low-grade paints are not suitable for facades.

How to choose the right paint

When choosing compositions for dyeing a false beam, the following general properties are taken into account:

- weather resistance;

- respect the environment;

- level of vapor permeability;

- lifetime.

If varnish is applied to the paint, it is better to purchase formulations from one manufacturer.Paints and varnishes of different brands are worse combined due to the difference in additional components, therefore, the service life of the coating is reduced.

Outside the house

To paint the exterior walls, choose wooden facade paints adapted to the climatic conditions of the region. Compositions for outdoor use can withstand a wide range of temperatures - from -50 to + 50 degrees.

Interior decoration of the premises

Before painting, choose between a transparent coating and an opaque coating. As with the choice of colors, the decision depends on individual preferences and the overall stylistic design of the house.

How to properly prepare the surface

The facade and interior imitation of wood are prepared in the following way:

- they clean the old emery paints or clean the new panels for better adhesion to the future coating;

- wood dust is wiped off with a dry cloth;

- treat the wood with an antiseptic impregnation or stain.

To increase adhesion and more reliable protection against rotting, imitation wood can be treated with a wood primer compatible in composition with paint or varnish.

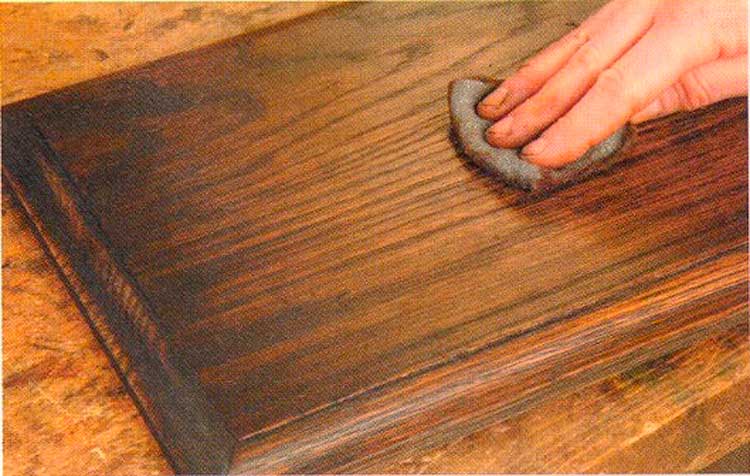

Before varnishing, it is recommended to additionally clean the panels with a wire brush or sponge in the direction of the grain.

Dyeing methods

In order to achieve a durable and beautiful coating, it is important to observe the technology of painting faux wood with different compositions.

Regular paints

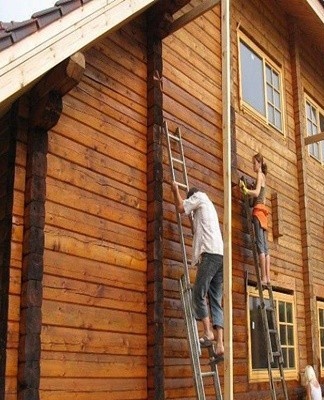

Coloring compositions are applied in two layers to the wood inside the room and in three layers to the imitation of the facade.

How to paint the panels:

- stir the paint, if necessary dilute it to medium viscosity with a solvent;

- start painting from the upper panels to the lower panels;

- apply the composition by roller or brush in a thin layer;

- carefully paint the corners, do not leave transparent places in the center.

The following layers are applied after drying of the previous ones.

Varnish application

Imitation of wood is varnished over the paint and immediately after preparing the surface.

Procedure:

- a thin first layer is evenly applied with a brush;

- after drying, grind with emery;

- cover the surface with a second coat of varnish.

Apply a third coat if necessary. The previous layers must be sanded so that the composition fills the grooves of the wood well and the coating is even. The more layers, the more intense the toning color.

Textured coloring

To preserve the wood pattern, the imitation wood is coated with glaze after preparation. The aging technique is also used:

- the surface is varnished;

- after drying, a thin layer of white water-based paint is applied;

- without waiting for complete drying, it is carried out on the painted surface with a dry cloth and partially cleaned of the white coating.

This way you can paint interior walls from a fake beam.

Features of the use of impregnations, wax and other paint materials

Impregnations and stains are applied along the fibers of the wood, moving gradually from bar to bar. The brush is dipped in the compositions to the middle so that the excess does not spread on the panels. Random drops should be immediately distributed on the surface, otherwise they will stick out under the dried coating.

For hair removal, a cloth is more often used, less often brushes.A small amount of the composition is rubbed in until an even, glossy layer forms. It is important to let the wax dry, but not to harden. The finished coating is wiped with a cotton cloth.

Additional tips and tricks

In order for the coating to serve for a long time, when finishing wood, it is worth paying attention to the following points:

- sanding clean wooden panels - this way you can avoid lifting the upper fibers, otherwise the surface will become rough and the dried coating will crack;

- carry out work outdoors and indoors at temperatures above 12 degrees Celsius;

- sanding intermediate coats of paint or varnish to form an even coating and avoid staining;

- apply new coats with clean brushes and rollers;

- do not apply paint in one thick layer - the coating will dry on the outside, but will remain wet on the inside and crack. The simulation panels are painted in several thin layers.

To check formulation compatibility and evaluate color, it is recommended that varnishes, paints and stains be tested on a separate panel.

Working examples

Imitation wood adorns the facade of the house, giving it the look of a hunting lodge or a log house. Horizontal panels are combined with other natural and artificial finishing materials: glass, stone, metal. Thanks to the smooth surface, wood finishes look organic in rooms decorated in modern and classic styles.

How to use imitation wood:

- combine with plaster - the facade looks elegant, the tandem of wood and plaster also looks original in the interior;

- overlap all exterior walls - a classic version of using a false beam;

- combine with the stone finish of the foundation - for lovers of solid buildings in the eco-style;

- highlight the exterior walls of the attic with a false beam - the design harmonizes with a stone facade and wrought iron decorative elements.

In the interior space of the house, prefabricated panels are used to decorate the hall, corridors and separate walls of rooms. Faux wood is suitable for zoning space, decorating stairs, and less often on the ceiling.