What are glaze paints and their types, how to choose a brand and use

Glazing coating is used in order to preserve the original pattern of the material, the paint provides tight adhesion to wood, protects against moisture, but at the same time gives an interesting shade. The glaze is translucent, but when mixed with an acrylic or alkyd base, it can provide any selected shade. The peculiarity of the colored coating is the creation of a unique pattern on the surface.

General Information Processing Compositions

Glazing is the technique of staining wood, the result of which is the reception of deep saturated patterns. The effect is achieved by applying translucent coatings. Glaze or glaze paints are usually called special translucent compositions, which are widely used in construction or industry.

If you varnish a wooden surface with a pronounced texture, you can get a glossy surface with a smooth surface and preserving the texture of the wood.

If you use a glaze to cover the plaster, you can expect an unusual volumetric surface. In addition to volume, you can change the hue by adding color.

Advantages and disadvantages

The window paint is suitable for indoor and outdoor use. It is suitable for the realization of the final decorative layer and consolidates the result.

| Advantage | The description |

| Moisture resistance | Materials are moisture resistant |

| Prevent sun exposure | Additionally tested for UV influence |

| Protection against dust and dirt | The top layer prevents dust from settling |

| Ease of use | Can be applied in any convenient way |

| No stains during work | Does not run after application |

Technologists mention such a glaze property as drying speed. Compared to other paints and varnishes, glaze paints dry in 3-4 hours. If necessary, after that, repeated layers are applied to the lower layer in order to achieve the desired shade.

The disadvantage of glaze paints is the need to comply with temperature indicators. When using coatings, moisture values must be taken into account. They affect the basic characteristics of paints. Products intended for outdoor use differ significantly from the compositions applicable to surfaces located inside various premises. Cannot replace formulations.

Main areas of application

Glazing paints are used after exterior or interior work. This is one of the finishing steps. Paints emphasize the characteristic relief of natural wood, and also give a glossy look to smooth surfaces.

Varieties

In order to choose the right composition, it is necessary to take into account the differences between the existing varieties of enamel paints. Some of them are intended only for interior decoration, others are suitable for exterior wall decoration.

Paints and varnishes

Glazing paints and varnishes - compositions on a translucent basis. The mixtures fix the final coating even on wooden surfaces:

- acrylic and oil paints are suitable for interior decoration;

- for exterior walls, polyurethane or alkyd-urethane compounds are used.

Reference! VGT paints are suitable for interior work. They are ecological and technologically efficient compounds that stand out for their wear resistance and durability.

The varnish provides a durable finish. It is used to decorate the walls of a house from the outside, like wooden boards. Well suited for log cabins, protects against moisture and dirt. Glaze varnishes are available in matt, semi-matt or glossy versions. They give a characteristic shine and level the surface.

Antiseptics

Antiseptic paints are compounds that protect wood from moisture and various formations. The top coat provides a natural semi-gloss shine. Antiseptic compositions dry quickly, do not require the application of several layers to achieve a result. The composition of the fixing antiseptic is supplemented with an alkyd or modified alkyd resin, as well as various oils with antiseptic properties. It is recommended to apply antiseptic glazing immediately after installing the frame. A thin layer makes the coating an obstacle to the spread of mold, blackening, blue discoloration.

Attention! Antiseptics begin to show wear resistance 4 weeks after application.

How to paint correctly

Paints and varnishes belonging to the glazing category are applied like conventional traditional paints. Before use, it is necessary to carefully prepare the surface to be treated.

Surface preparation

To ensure maximum adhesion, the old layer of paint is completely removed. Remove accumulated dirt with a spatula or construction hair dryer. If necessary, use coarse sandpaper or an abrasive wheel.

Irregularities and cracks are sealed with putty, the surface is leveled and treated with a degreaser or solvent. This helps remove any remaining oily stains or hard-to-reach dirt particles.

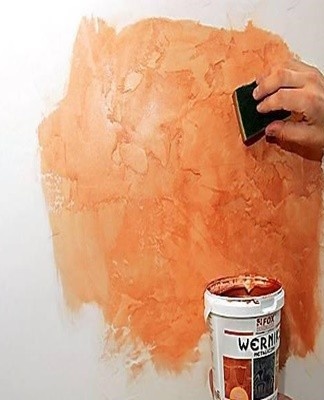

Dyeing

Paint is applied to the treated surface with a soft sponge, brush or special construction gloves. The strokes are wide, directing them in different directions. Smooth strokes will provide even surface coverage. It is recommended to dilute the first layer of glaze with water or solvent. After the first layer is completely dry, the next layer is applied undiluted.

Calculation of consumption

Criteria to consider when calculating the amount of paint:

- method of application;

- the quality of the tool used (roller, brush, spray);

- surface characteristics: roughness, absorbency;

- painted surface area.

To plan the purchase of consumables, you must:

- determine the area to be painted;

- then divide the indicator by the value indicated on the packaging as material consumption;

- multiply by the number of assumed layers;

- it is recommended to round the resulting number to the nearest whole number.

Attention! When working with tinting elements, a small margin should be left.

Recommendations for choosing a brand

Manufacturers of glazing materials recommend purchasing products taking into account the characteristics of the treated surface. Manufacturing companies indicate the preferred type of surface on the packaging of the boxes to make it easier for customers to choose.

For timber after felling

The tree after felling must be treated with an antiseptic. This helps protect the material from rotting or mold. Antiseptic solutions are applied with a spray, paying special attention to the contact points of the logs. BiO LASUR by PROSEPT is a topcoat with a decorative effect.

For logs with natural humidity

Paintings exposed to water have special characteristics. It is recommended to apply them in 2 or 3 layers. This allows you to achieve the maximum result. Valtti Color by Tikkurila is designed to paint log walls and horizontal surfaces naturally exposed to moisture.

For the treatment of rafters

The rafter system requires special treatment. The structure is mobile type and is designed to contain elements. Valtti Color Satin paint is an enamel paint used to treat external sawn and planed wooden surfaces.

For the prevention of fungus and mold

Valtti Color Extra promotes the formation of a protective film that looks like varnish.

For baths and saunas

Baths and saunas are recommended to be treated with compounds that protect the tree from moisture and premature decay. Constant exposure to steam and high temperatures contributes to the active aging of wood, so it is important to choose compounds that additionally protect surfaces. The bath lacquer, which contains Aqualak Eurotex Sauna wax, can be applied to all interior surfaces, with the exception of the canopy.

To stain wood

Wood of different ages and types of processing is painted with glaze paints with pronounced antiseptic qualities. SENEZH AQUADECOR is an antiseptic from a Russian manufacturer. It is applicable for indoor and outdoor use.

For decorative plaster

Processing plaster with glaze paints performs several tasks at the same time:

- emphasizes texture;

- enriches the color gamut;

- improves contouring;

- creates a unique decorative hold.

Gallery Glaze is a translucent layer that creates a pearlescent effect on textured and smooth surfaces.

Additional tips and tricks

Glaze paints are applied in different ways to prepared surfaces. The choice of tool depends on several factors:

- Sponge. The main method of application is the use of a synthetic sponge. This helps to emphasize the texture characteristics of the canvas.

- The brush is wide. This tool is essential when painting in corners or hard-to-reach areas.

- Roll. It is recommended to use it for large areas.

- Construction mitt. Special tool for processing Venetian plaster.

- Rubber sponge. The adjuster reduces the contrast.

- The spatula is wide.Helps to apply a thin layer of glazing compound on decorative plaster with a special relief.

When processing the surface, it should be borne in mind that the next layer is superimposed on the previous layer, provided that it is completely dry.